MIT Chemical Engineers Develop New Way To Separate Crude Oil

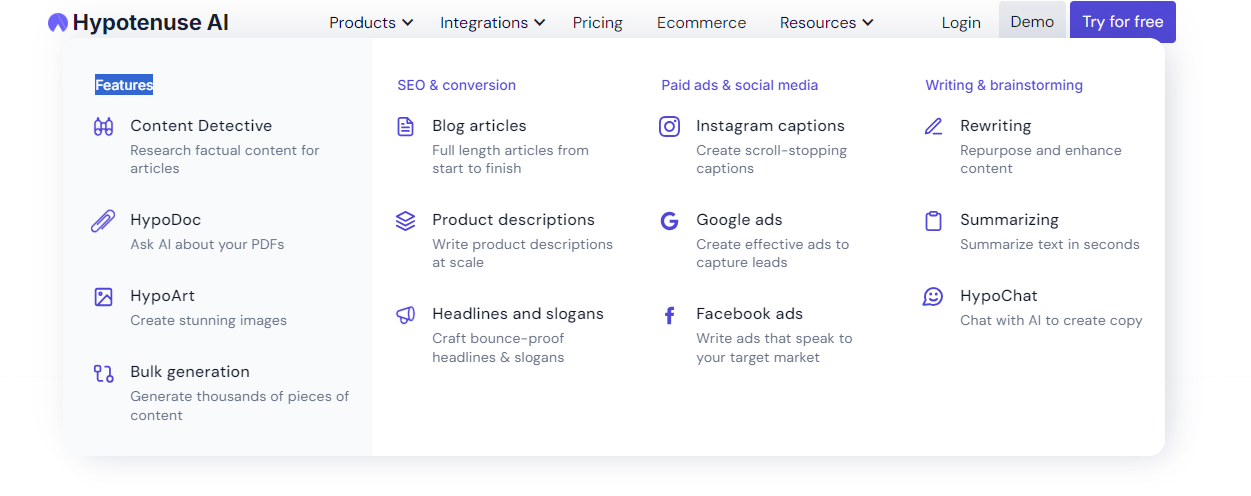

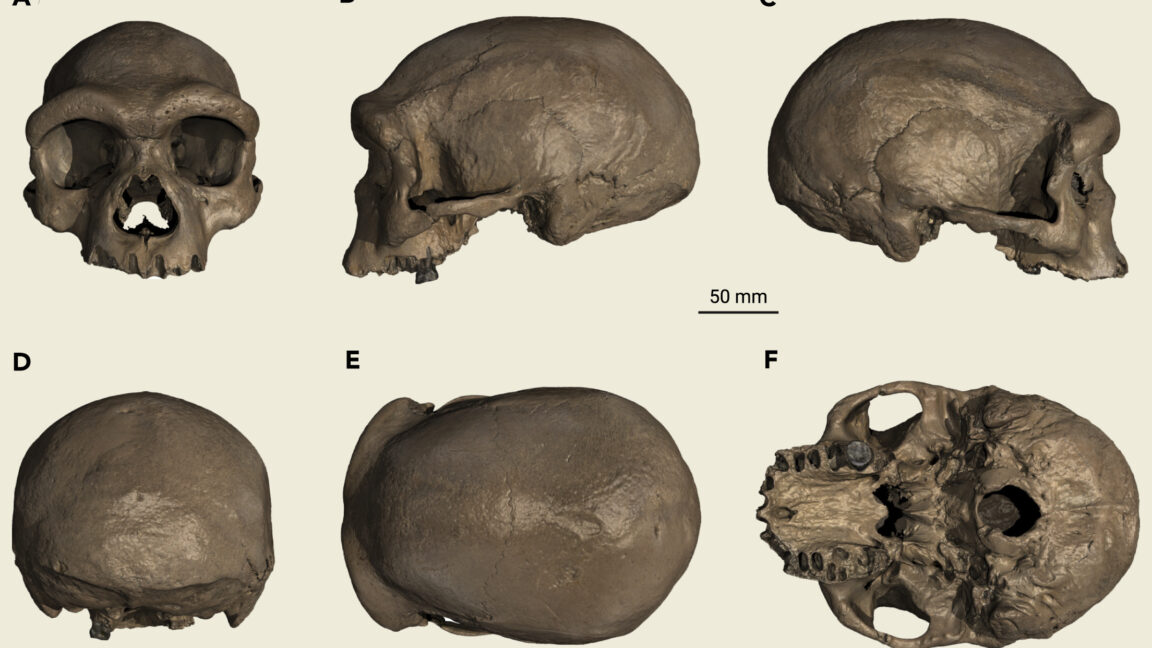

Longtime Slashdot reader fahrbot-bot shares a report from the Cool Down: A team of chemical engineers at the Massachusetts Institute of Technology has invented a new process to separate crude oil components, potentially bringing forward a replacement that can cut its harmful carbon pollution by 90%. The original technique, which uses heat to separate crude oil into gasoline, diesel, and heating oil, accounts for roughly 1% of all global energy consumption and 6% of dirty energy pollution from the carbon dioxide it releases. "Instead of boiling mixtures to purify them, why not separate components based on shape and size?" said Zachary P. Smith, associate professor of chemical engineering at MIT and senior author of the study, as previously reported in Interesting Engineering. The team invented a polymer membrane that divides crude oil into its various uses like a sieve. The new process follows a similar strategy used by the water industry for desalination, which uses reverse osmosis membranes and has been around since the 1970s. [The membrane excelled in lab tests. It increased the toluene concentration by 20 times in a mixture with triisopropylbenzene. It also effectively separated real industrial oil samples containing naphtha, kerosene, and diesel.] Read more of this story at Slashdot.

Read more of this story at Slashdot.

![[The AI Show Episode 154]: AI Answers: The Future of AI Agents at Work, Building an AI Roadmap, Choosing the Right Tools, & Responsible AI Use](https://www.marketingaiinstitute.com/hubfs/ep%20154%20cover.png)

![[The AI Show Episode 153]: OpenAI Releases o3-Pro, Disney Sues Midjourney, Altman: “Gentle Singularity” Is Here, AI and Jobs & News Sites Getting Crushed by AI Search](https://www.marketingaiinstitute.com/hubfs/ep%20153%20cover.png)

![[DEALS] Internxt Cloud Storage Lifetime Subscription (20TB) (89% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

![GrandChase tier list of the best characters available [June 2025]](https://media.pocketgamer.com/artwork/na-33057-1637756796/grandchase-ios-android-3rd-anniversary.jpg?#)

.png?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

_Paul_Markillie_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

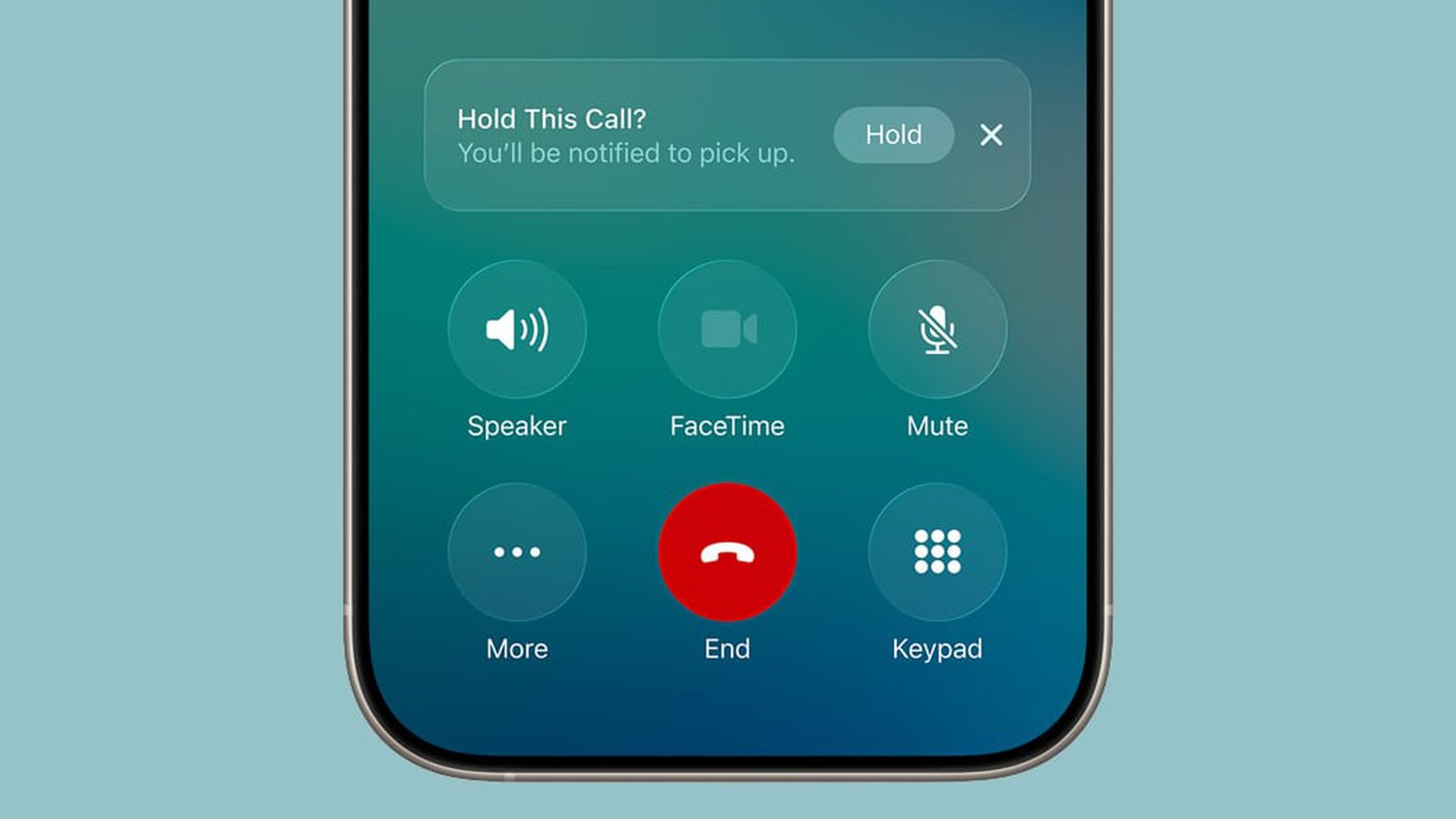

![It wasn't just you, Apple Intelligence was down [u]](https://photos5.appleinsider.com/gallery/64086-133417-IMG_2283-xl.jpg)

![Samsung has its own earthquake alert system with options Google should consider [Gallery]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/02/Galaxy-S25-Ultra-Titanium-Jadegreen-1.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![iPhone 18 Pro Models to Feature Under-Display Face ID, Keep Same Display Sizes [Rumor]](https://www.iclarified.com/images/news/97657/97657/97657-640.jpg)

![Apple M4 Mac Mini Drops to Just $469 — Save $130 [Lowest Price Ever]](https://www.iclarified.com/images/news/97659/97659/97659-640.jpg)

![Mobile Legends: Bang Bang [MLBB] Free Redeem Codes June 2025](https://www.talkandroid.com/wp-content/uploads/2024/07/Screenshot_20240704-093036_Mobile-Legends-Bang-Bang.jpg)

![It's Not Just You: Apple Intelligence is Down on iOS 26 and Other Betas [Fixed]](https://images.macrumors.com/t/p817t4gw5ljW1ROSxfadhn3mJew=/2500x/article-new/2025/06/iOS-26-Feature.jpg)