The Future of Manufacturing with Microsoft Dynamics 365 is Here—Are You Ready?

Industry 4.0 has found itself a major topic of discussion in recent years. Manufacturing remains at the center of this revolution. Modern technologies are reshaping supply chains, production lines and customer expectations. To ensure success, you need to evolve. Microsoft Dynamics 365 is at the forefront of this transformation, offering a comprehensive suite of tools which can be fundamental in making your business future-proof. In this article, we will be taking a look at how Microsoft Dynamics 365 is shaping the future of manufacturing, and the most important question – are you ready? ** AI in Microsoft Dynamics 365 – Paving the Way for Smarter Manufacturing ** Artificial Intelligence is embedded directly into different Dynamics 365 modules like Supply Chain Management, Sales and Customer Insights. AI models in D365 allow businesses to unlock deeper insights, streamline operations and predict future outcomes with considerable accuracy. Here are some of the ways Microsoft is leveraging AI technology within Dynamics 365: Predictive Maintenance: Dynamics 365 uses real-time sensor data from your production line to predict potential equipment failures, long before they become a reality. This helps you to take proactive actions, effectively reducing downtime and maintenance costs. Intelligent Order Management: AI in Dynamics 365 ERP modules can streamline the order lifecycle by routing orders in real-time to the best fulfillment option based on factors like inventory levels, delivery timelines and logistics costs. Microsoft Copilot AI: Microsoft Copilot is a digital AI assistant that is integrated across all Dynamics 365 modules. You can engage with it conversationally and execute a wide range of tasks including generating reports, summarizing meetings, or even providing insights from your data. *Real-Time Visibility with Intelligent IoT Integration * Internet of Things (IoT) has become mainstream in modern manufacturing operations. However, businesses, especially medium-scale enterprises, often feel that they don’t get enough value out of it. But with the latest advancements in Dynamics 365, you can tap into the full potential of your IoT network. Dynamics 365 integrates seamlessly with Azure IoT which makes it easy to ingest data in real time from machines, devices and sensors on the factory floor. This gives you real time insights into equipment performance, energy consumption, and identify operational bottlenecks. Here are some of the scenarios in which it can help your manufacturing business You will be able to monitor environmental conditions to maintain quality standards. Managers will be able to adjust production flow based on the rate of equipment utilization. It can also play a fundamental role in running operational simulations, which will help in planning and strategizing. By gathering constant feedback from the factory floor, and real-time data analytics, you can operate with increased agility and take proactive actions that save you money and also give you a competitive edge. Are You Ready for Digital Transformation with Dynamics 365? Now, the important question is – is your business equipped to embrace the future of manufacturing by tapping into Dynamics 365? Several manufacturers are held back by legacy systems, data silos or even resistance from their employees to change. This is what prevents them from digitally transforming their operations for the future with the help of Microsoft Dynamics 365. Now, here are some of the important questions that you need to ask to assess your readiness for moving to Dynamics 365 Are you currently running cloud-based systems, or do you still rely on dated on-premises solutions? Does your workforce possess the necessary skills to work with AI, automation and next generation automation? How quickly do you think your team can adapt to any possible supply chain disruptions or shifts in customer demands? Are your ERP and CRM systems integrated with each other, or do they work in silos? Answers to these questions will provide you with a roadmap for the approach that you need to take when it comes to starting with Dynamics 365. This will also help you to set realistic goals and milestones and set the right expectations when you are looking to switch from your existing processes to Dynamics 365. *How Can a Consultant Help You Implement Dynamics 365? * Now, one of the most common questions that businesses have is whether they should work with a Dynamics 365 consultant. Well, there is no definite answer to this question. It depends on the kind of infrastructure and IT support you have and whether or not they will be able to support your operations when you are making the transition to Dynamics 365. Working with a certified Microsoft 365 consultant does have its own advantages. Here are few key ones: *Accurate Discovery and Readiness Assessment * Analyzing your existing

Industry 4.0 has found itself a major topic of discussion in recent years. Manufacturing remains at the center of this revolution. Modern technologies are reshaping supply chains, production lines and customer expectations. To ensure success, you need to evolve. Microsoft Dynamics 365 is at the forefront of this transformation, offering a comprehensive suite of tools which can be fundamental in making your business future-proof.

In this article, we will be taking a look at how Microsoft Dynamics 365 is shaping the future of manufacturing, and the most important question – are you ready?

**

AI in Microsoft Dynamics 365 – Paving the Way for Smarter Manufacturing

**

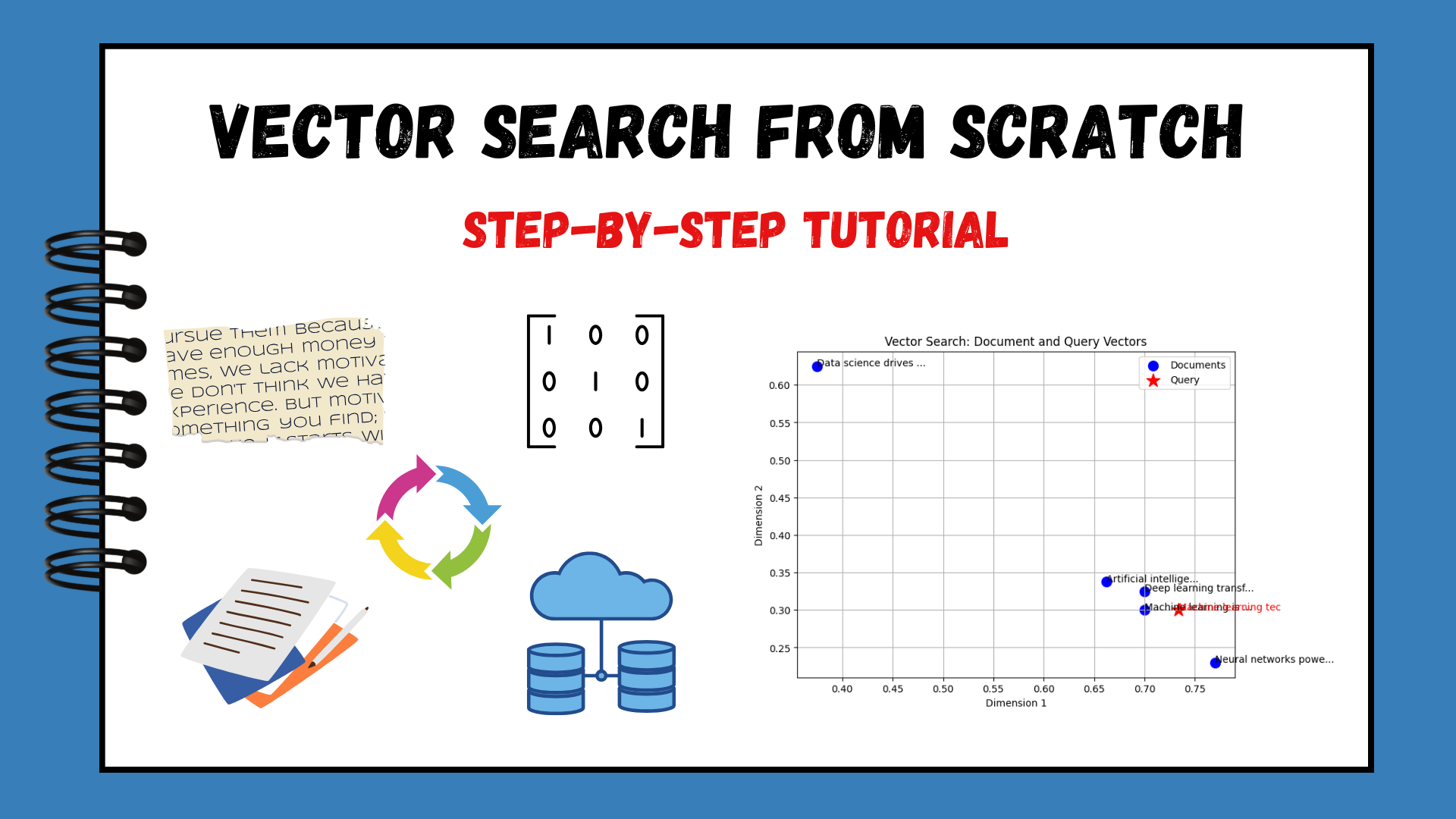

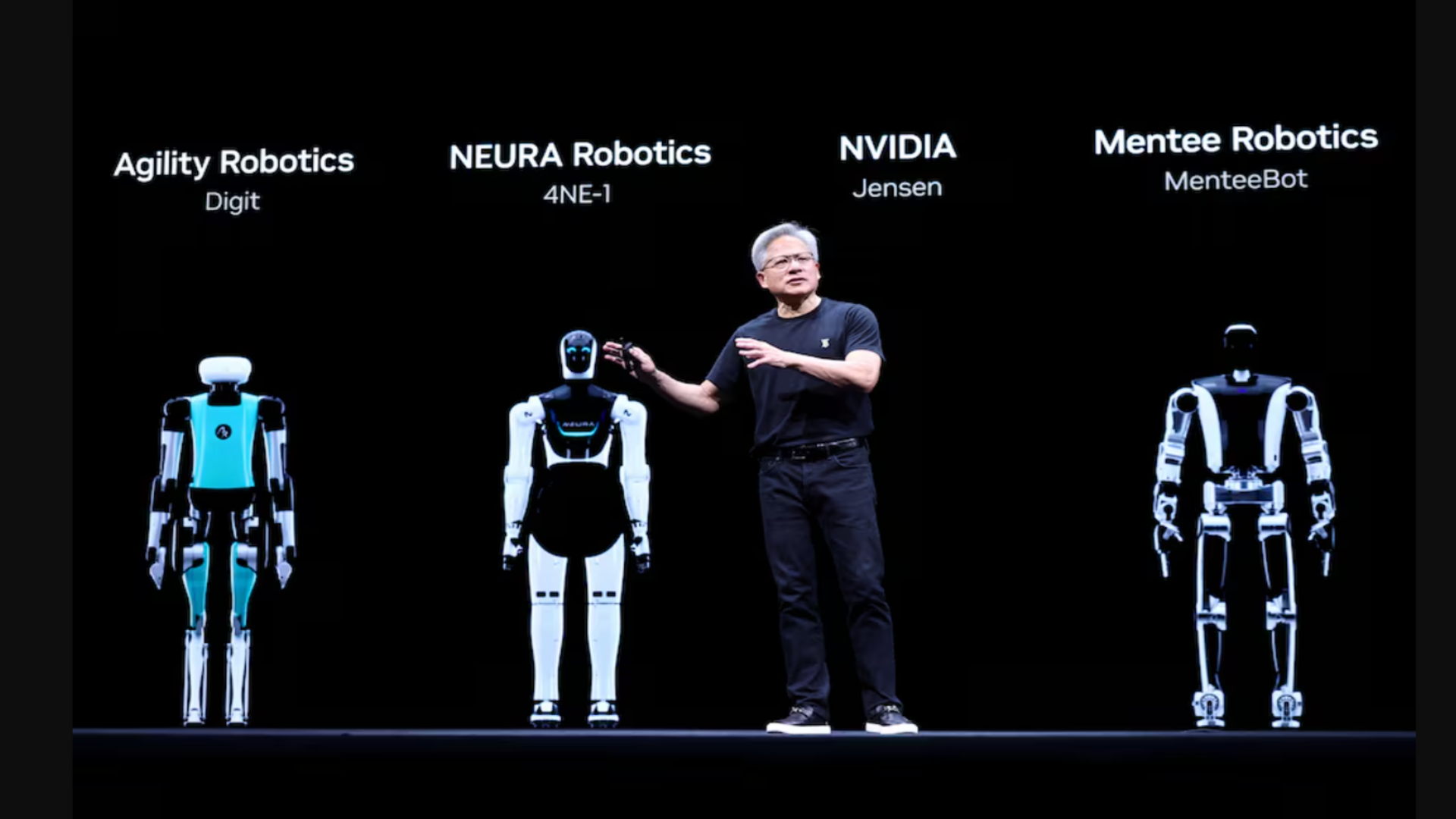

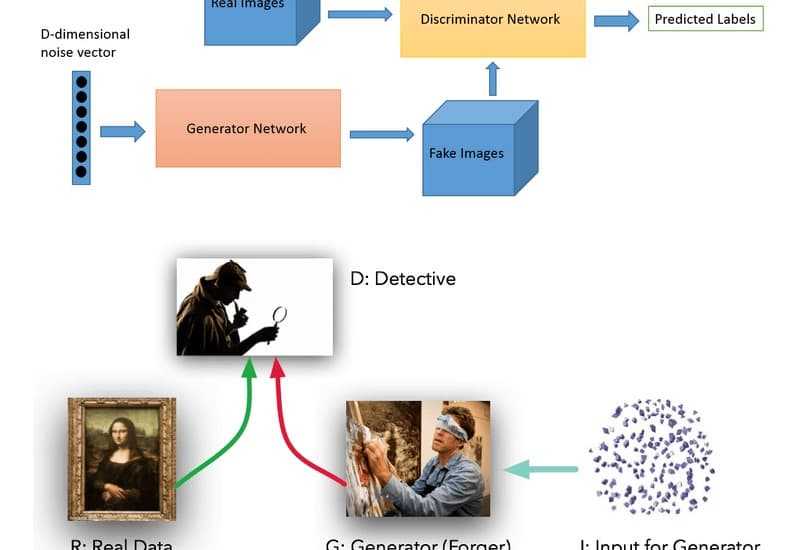

Artificial Intelligence is embedded directly into different Dynamics 365 modules like Supply Chain Management, Sales and Customer Insights. AI models in D365 allow businesses to unlock deeper insights, streamline operations and predict future outcomes with considerable accuracy.

Here are some of the ways Microsoft is leveraging AI technology within Dynamics 365:

Predictive Maintenance: Dynamics 365 uses real-time sensor data from your production line to predict potential equipment failures, long before they become a reality. This helps you to take proactive actions, effectively reducing downtime and maintenance costs.

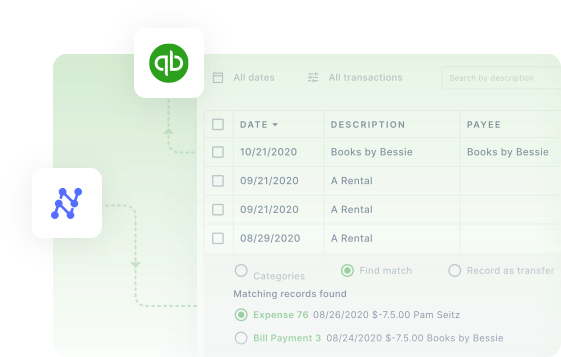

Intelligent Order Management: AI in Dynamics 365 ERP modules can streamline the order lifecycle by routing orders in real-time to the best fulfillment option based on factors like inventory levels, delivery timelines and logistics costs.

Microsoft Copilot AI: Microsoft Copilot is a digital AI assistant that is integrated across all Dynamics 365 modules. You can engage with it conversationally and execute a wide range of tasks including generating reports, summarizing meetings, or even providing insights from your data.

*Real-Time Visibility with Intelligent IoT Integration *

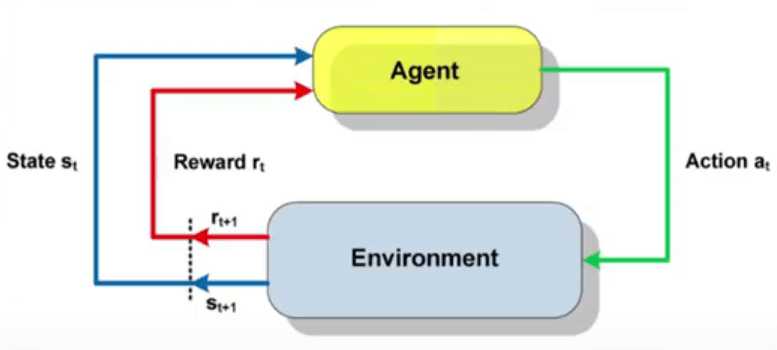

Internet of Things (IoT) has become mainstream in modern manufacturing operations. However, businesses, especially medium-scale enterprises, often feel that they don’t get enough value out of it.

But with the latest advancements in Dynamics 365, you can tap into the full potential of your IoT network.

Dynamics 365 integrates seamlessly with Azure IoT which makes it easy to ingest data in real time from machines, devices and sensors on the factory floor. This gives you real time insights into equipment performance, energy consumption, and identify operational bottlenecks.

Here are some of the scenarios in which it can help your manufacturing business

You will be able to monitor environmental conditions to maintain quality standards.

Managers will be able to adjust production flow based on the rate of equipment utilization.

It can also play a fundamental role in running operational simulations, which will help in planning and strategizing.

By gathering constant feedback from the factory floor, and real-time data analytics, you can operate with increased agility and take proactive actions that save you money and also give you a competitive edge.

Are You Ready for Digital Transformation with Dynamics 365?

Now, the important question is – is your business equipped to embrace the future of manufacturing by tapping into Dynamics 365?

Several manufacturers are held back by legacy systems, data silos or even resistance from their employees to change. This is what prevents them from digitally transforming their operations for the future with the help of Microsoft Dynamics 365.

Now, here are some of the important questions that you need to ask to assess your readiness for moving to Dynamics 365

Are you currently running cloud-based systems, or do you still rely on dated on-premises solutions?

Does your workforce possess the necessary skills to work with AI, automation and next generation automation?

How quickly do you think your team can adapt to any possible supply chain disruptions or shifts in customer demands?

Are your ERP and CRM systems integrated with each other, or do they work in silos?

Answers to these questions will provide you with a roadmap for the approach that you need to take when it comes to starting with Dynamics 365. This will also help you to set realistic goals and milestones and set the right expectations when you are looking to switch from your existing processes to Dynamics 365.

*How Can a Consultant Help You Implement Dynamics 365? *

Now, one of the most common questions that businesses have is whether they should work with a Dynamics 365 consultant.

Well, there is no definite answer to this question. It depends on the kind of infrastructure and IT support you have and whether or not they will be able to support your operations when you are making the transition to Dynamics 365.

Working with a certified Microsoft 365 consultant does have its own advantages. Here are few key ones:

*Accurate Discovery and Readiness Assessment

*

Analyzing your existing system is important to determine your approach. A consultant will help you in accurate analysis, identifying gaps, and the steps that need to be taken to align the platform with your business goals.

*Solution Design and Customization *

Your manufacturing operation is unique. Therefore, you need to get a solution that is as unique as your operations. A consultant will help you choose the right modules and integrate them with your existing systems and processes.

*Data Migration and Integration

*

Migrating data from your existing manufacturing ERP and CRM platforms to Dynamics 365 is crucial for implementing it for your business. A consultant ensures that the data is cleansed, mapped and transferred correctly. They will also assist you with managing user roles, security settings and business rules to enhance efficiency without causing disruption.

*Training and Support

*

User adoption is important to ensure the desired ROI from Dynamics 365. A certified consultant will offer you comprehensive training programs and documentation that will make your teams become confident users.

They will also monitor the system performance and offer support and continuously optimize the process and make it evolve as your needs and market demands change.

Microsoft Dynamics 365 is an intelligent, adaptable platform that is built for the future of manufacturing. It can help you make AI driven decisions, take proactive actions and understand customer behavior in a way that gives you a competitive advantage.

But just having access to the right technology is not enough. You need vision, leadership and of course, the right partner to power the transformation and ensure success.

So, get in touch with the right Dynamics 365 consulting partner and make your manufacturing operations ready to capitalize on the exciting opportunities in the future.

![[The AI Show Episode 156]: AI Answers - Data Privacy, AI Roadmaps, Regulated Industries, Selling AI to the C-Suite & Change Management](https://www.marketingaiinstitute.com/hubfs/ep%20156%20cover.png)

![[The AI Show Episode 155]: The New Jobs AI Will Create, Amazon CEO: AI Will Cut Jobs, Your Brain on ChatGPT, Possible OpenAI-Microsoft Breakup & Veo 3 IP Issues](https://www.marketingaiinstitute.com/hubfs/ep%20155%20cover.png)

![Rust VS Go VS TypeScript – which back end language is for you? With Tai Groot [Podcast #176]](https://cdn.hashnode.com/res/hashnode/image/upload/v1750974265013/73f79068-0087-4c39-8a8b-feea8cac873b.png?#)

.jpg?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)