Inside the Amazon lab that could change the way we recycle plastic

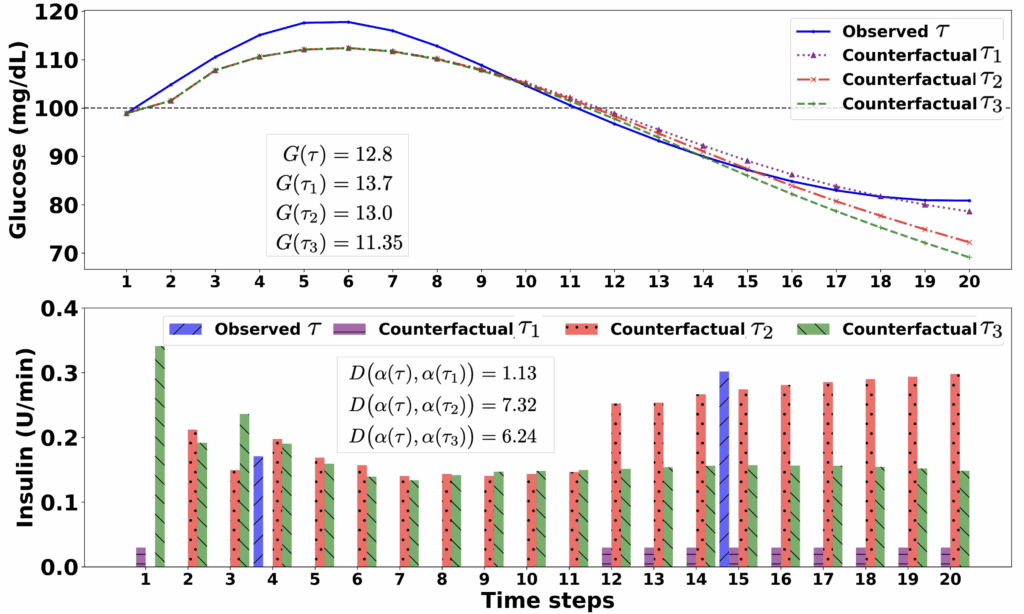

There’s no question that Amazon is known for its packaging. Boxes and mailers with the ubiquitous smile logo now dot the porches of every neighborhood in the country. And with the company’s 2017 purchase of Whole Foods, it became a major player in food packaging as well, wrapping everything from produce to potato chips. Since then, the chain has expanded to 535 locations and increased its sales 40%. That means that every day, millions of people take home some food wrapped in plastic from Whole Foods—but probably rarely think about the packaging. But in a nondescript warehouse in a still-industrial part of Seattle, five scientists at Amazon’s Sustainable Materials Innovation Lab are trying to design a better package.This work is twofold. First, researchers are putting dozens of bio-based plastics through a gauntlet of tests on things like tensile strength, tear strength, and seal strength to see how they compare to their fossil-fuel-based counterparts. Second, they’re working with a handful of partners to make sure that when this packaging hits the market, there’s a recycling infrastructure already in place that can support it.[Photo: courtesy Amazon]“Our long-term objective is to enable simplicity and recycling of plastics in the same way that you have paper today,” says Alan Jacobsen, the director of Materials and Energy Sciences at the lab. “You don’t need to know, is it a 1, 2, 3, 4. You just throw it.”The intense focus on circularity sands in stark contrast to the overconsumption that Amazon’s business model entails—and the vast amounts of junk it distributes, particularly with the recent launch of Haul, where every item is under $20. Jacobsen, for his part, says that he knows people are going to buy products at “a range of price points. . . . We try to figure out how to enable that in the most sustainable way.” And the company says it intends to make the research and technology available beyond Amazon, which means that if it’s successful, it could lead to a fundamental change in packaging—and recycling—throughout the economy.[Photo: courtesy Amazon]The challenges of designing food packagingLast October, Amazon announced that it had swapped out all of its plastic fillers with paper, part of its overall commitment to reducing plastic use. Paper isn’t just more environmentally friendly than plastic, it also has much higher rates of recycling (68% compared to 6%). “When you’re at home recycling paper, you just throw it in the bin and you know it’s going to get recycled,” Jacobsen says. “Because it’s easier to recycle, it’s recycled more.”But for some applications, paper just isn’t a viable solution. That’s especially true for food packaging “because of the physical properties of the material,” says Jacobsen. “Sometimes this has to do with the tear strength or puncture strength; sometimes it has to do with the moisture barrier properties or oxygen barrier properties—just properties that it is not possible for paper to meet.”Food packaging has to keep potato chips crispy and pretzels salty and baby carrots wet; it has to be tough enough that a pile of apples don’t tear open the bag, with a seal strong enough that frozen peas don’t spill all over the floor (while still being easy to open). Food has way more demands of its packaging than something like a book, a tube of lipstick, or even a set of dishes. The default solution to this has always been plastic. But Jacobsen and his team are working on a replacement: biopolyesters. That means the plastic is biodegradable and uses biological materials, waste, or recycled content as the feedstock (or raw material used to make the plastic). [Photo: courtesy Amazon]But this packaging doesn’t just have to be developed, tested, and produced—Amazon also wants it to be easily recyclable, which is where things get even more complicated. Our current recycling infrastructure is finicky: It’s not good at differentiating between different types of plastic, and if it gets confused, it errs on the side of landfill. (Because if the different types of plastic get bundled together, it downgrades the entire bale, which means less money for the recycling facility.)Jacobsen and his team want to eliminate this problem entirely. They want to make biopolyesters that are a blend of feedstocks (including different types of recycled plastic) and then have recycling plants (called “materials recovery facilities,” or MRFs) be able to take it all in, easily separate it, and find a home for these streams.“But one new type of material is not going to work,” says Jacobsen. “You’re going to need a range of different materials. You often have to blend these materials together. You have to put them in different layers to meet the requirements for a particular application.” But most recycling facilities aren’t set up to deal with these kinds of mixed waste streams in a single piece of packaging. So Amazon is working with a network of other companies to help redesign the plastic recycling infrastructur

There’s no question that Amazon is known for its packaging. Boxes and mailers with the ubiquitous smile logo now dot the porches of every neighborhood in the country. And with the company’s 2017 purchase of Whole Foods, it became a major player in food packaging as well, wrapping everything from produce to potato chips.

Since then, the chain has expanded to 535 locations and increased its sales 40%. That means that every day, millions of people take home some food wrapped in plastic from Whole Foods—but probably rarely think about the packaging. But in a nondescript warehouse in a still-industrial part of Seattle, five scientists at Amazon’s Sustainable Materials Innovation Lab are trying to design a better package.

This work is twofold. First, researchers are putting dozens of bio-based plastics through a gauntlet of tests on things like tensile strength, tear strength, and seal strength to see how they compare to their fossil-fuel-based counterparts. Second, they’re working with a handful of partners to make sure that when this packaging hits the market, there’s a recycling infrastructure already in place that can support it.

“Our long-term objective is to enable simplicity and recycling of plastics in the same way that you have paper today,” says Alan Jacobsen, the director of Materials and Energy Sciences at the lab. “You don’t need to know, is it a 1, 2, 3, 4. You just throw it.”

The intense focus on circularity sands in stark contrast to the overconsumption that Amazon’s business model entails—and the vast amounts of junk it distributes, particularly with the recent launch of Haul, where every item is under $20. Jacobsen, for his part, says that he knows people are going to buy products at “a range of price points. . . . We try to figure out how to enable that in the most sustainable way.” And the company says it intends to make the research and technology available beyond Amazon, which means that if it’s successful, it could lead to a fundamental change in packaging—and recycling—throughout the economy.

The challenges of designing food packaging

Last October, Amazon announced that it had swapped out all of its plastic fillers with paper, part of its overall commitment to reducing plastic use. Paper isn’t just more environmentally friendly than plastic, it also has much higher rates of recycling (68% compared to 6%). “When you’re at home recycling paper, you just throw it in the bin and you know it’s going to get recycled,” Jacobsen says. “Because it’s easier to recycle, it’s recycled more.”

But for some applications, paper just isn’t a viable solution. That’s especially true for food packaging “because of the physical properties of the material,” says Jacobsen. “Sometimes this has to do with the tear strength or puncture strength; sometimes it has to do with the moisture barrier properties or oxygen barrier properties—just properties that it is not possible for paper to meet.”

Food packaging has to keep potato chips crispy and pretzels salty and baby carrots wet; it has to be tough enough that a pile of apples don’t tear open the bag, with a seal strong enough that frozen peas don’t spill all over the floor (while still being easy to open). Food has way more demands of its packaging than something like a book, a tube of lipstick, or even a set of dishes.

The default solution to this has always been plastic. But Jacobsen and his team are working on a replacement: biopolyesters. That means the plastic is biodegradable and uses biological materials, waste, or recycled content as the feedstock (or raw material used to make the plastic).

But this packaging doesn’t just have to be developed, tested, and produced—Amazon also wants it to be easily recyclable, which is where things get even more complicated. Our current recycling infrastructure is finicky: It’s not good at differentiating between different types of plastic, and if it gets confused, it errs on the side of landfill. (Because if the different types of plastic get bundled together, it downgrades the entire bale, which means less money for the recycling facility.)

Jacobsen and his team want to eliminate this problem entirely. They want to make biopolyesters that are a blend of feedstocks (including different types of recycled plastic) and then have recycling plants (called “materials recovery facilities,” or MRFs) be able to take it all in, easily separate it, and find a home for these streams.

“But one new type of material is not going to work,” says Jacobsen. “You’re going to need a range of different materials. You often have to blend these materials together. You have to put them in different layers to meet the requirements for a particular application.”

But most recycling facilities aren’t set up to deal with these kinds of mixed waste streams in a single piece of packaging. So Amazon is working with a network of other companies to help redesign the plastic recycling infrastructure to make it simple for their designs to always be made into something new.

Glacier—designing robots to go through the trash

Much of the recycling infrastructure in the United States is built on MRFs. These massive warehouses take in gobs of recycling—cardboard boxes and wine bottles and take-out containers and everything in between—and sort hundreds of tons of waste each day. But in the course of that sorting, a lot of otherwise recyclable stuff can get missed or thrown out, maybe because the machines can’t tell what it is, maybe because it gets mixed in with other items. That means a lot of theoretically recyclable materials get sent to the landfill, and also that a lot of bundles of recycled plastic are too degraded with other materials to be properly reused.

Glacier, a San Francisco-based company that Amazon invested in last fall, designed a robot to eliminate these pain points. It can sort through more than 30 different types of material, meaning the end bales are more accurate, and fewer items get trashed. (One company, for example, added a Glacier robot, and found that its paper bales were 17% more pure as a result.)

“Our society tends to view recycling as a nice alternative to landfilling our trash,” says Rebecca Hu-Thrams, one of the cofounders. “[But] we very much see recycling as an absolutely crucial pillar of society’s necessary transition toward circular manufacturing. In other words, recycling is at its core a way to get your hands on more raw feedstocks, more materials to turn into new stuff.”

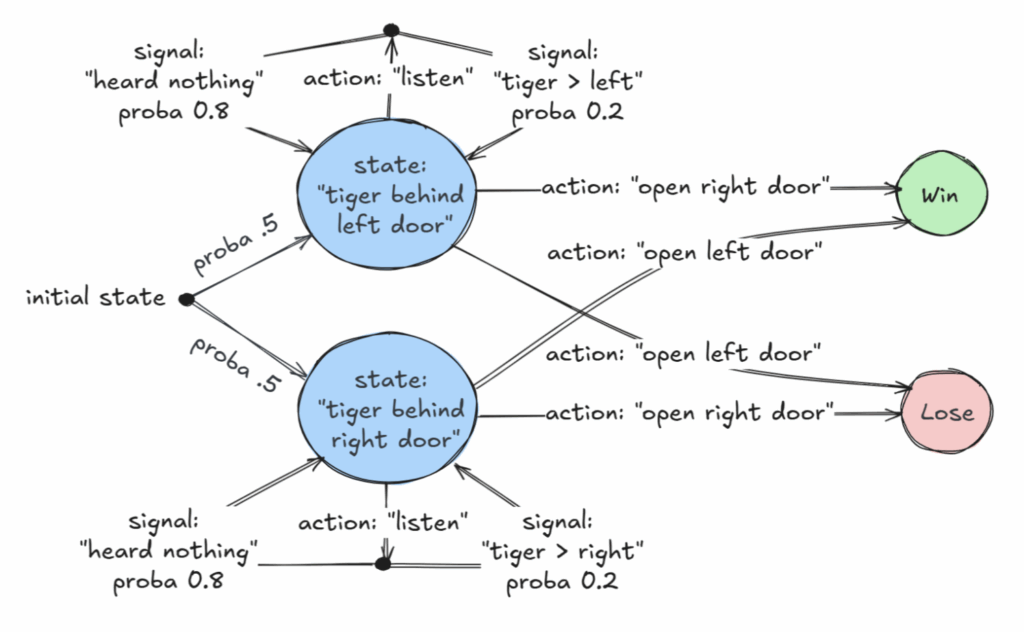

Hu-Thrams referenced a customer in the Midwest that installed one of Glacier’s AI camera’s on what’s known as a “last chance line,” where all the trash leaves the facility and there’s one more shot to pick out recyclable items. This facility quickly realized that about two-thirds of its total “leakage” was coming from beverage bottles; when they identified where and why this was happening, they were able to fix the issue.

“So in the span of a couple of weeks or less, they actually are now on track to rescue 15 million more of these PET bottles every single year that would’ve ended up in landfill,” says Areeb Malik, Glacier’s other cofounder.

Amazon plans to install one of these robotic systems in its lab next month. The goal is that as they develop new biopolyesters that are a mix of materials, they can simultaneously be training the system to recognize them and mark them as recyclable—never getting confused and thinking they belong in the trash.

“We want to make sure that once the materials are out in the market, we know that they’ll be identified in these systems right away,” says John Shane, a principal materials engineer who worked in Amazon’s lab for three years. “And we’ll be able to generate data sets here that we can share with Glacier and then they can share with their customers.” As that information is fed back to the companies, they’ll ideally be able to design packaging that’s easier to recycle (and better identified by the robot).

That’s a huge priority for Amazon, which plans to share what it learns from its biopolyester development. “We don’t want to own the IP and keep it to ourselves,” says Jacobsen. “We want everybody to have access; we have no financial motivation.”

EsterCycle—designing chemicals to break down the plastics

But even if Glacier’s tech scales up and is able to identify much more theoretically recyclable plastic, the current recycling infrastructure isn’t necessarily able to transform that into new products.

And that’s the problem EsterCycle is trying to solve. The Denver-based startup spun out of the National Renewable Energy Laboratory last August, after completing a successful project with Amazon on mixed recycling waste. Julia Curley was a postdoctoral researcher at NREL working on the project; she’s now EsterCycle’s founder and only full-time employee.

Curley stresses that EsterCycle isn’t looking to upend traditional recycling processes—it’s developing an entirely new one. The goal is to be additive to the current system, taking what MRFs now see as contaminated, lower quality plastic and transforming it into materials that can be made into new products.

Our existing system essentially collects bales of similar plastic; shreds, washes, and melts it; and then turns it into something new: It’s a mechanical process.

EsterCycle, on the other hand, is working on chemical recycling. “Plastics are made of these long chains of molecules called polymers,” Curley says. “And what we’re doing is actually cutting that chain into its individual components, kind of like taking apart a large string of Legos into its individual pieces. And then they can be remade into new plastics.” (Some environmental groups criticize wide-scale chemical recycling as being a pipe dream of Big Oil, although most of the research in this area thus far solely relates to fossil-fuel-based plastic.)

This will be especially relevant for compostable plastics, which are commonly used in food packaging. While this is still a small portion of overall plastic (just 1%, as of 2024), it’s projected to keep increasing—and our current infrastructure isn’t designed to recycle it. Curley says that currently, if too much of it is in a recycling bale, it will significantly lower the quality and price that a MRF can ask for it. Commercial composters, meanwhile, often don’t accept it either, because of contamination issues, or because they’re skeptical that it actually breaks down.

EsterCycle is now using a lot of these compostable plastics as feedstocks to demonstrate how well its chemical process works at breaking them down and making them usable for the supply chain.

As EsterCycle breaks down these kinds of plastics, the resulting “building blocks” can be sold to any kind of manufacturer. “The idea is that they can be drop-in additions to existing manufacturing, meaning the process doesn’t have to change at all,” Curley says.

Novamont—designing packaging to be recycled

Novamont, an Italian company, has been working on biodegradable and compostable products since its launch in 1990—and it’s exactly the kind of company that might buy those building blocks. Its Mater-Bi is used in things like shopping bags and packaging; while it was originally made out of fossil-fuel-produced polyesters, the company has been working to increase the amount of renewable content in this material.

While EsterCycle isn’t yet sending its feedstock their way, the idea is that ultimately, Novamont and similar companies would be able to seamlessly incorporate those biopolyesters into their products.

In the meantime, Amazon and Novamont are testing out bio-based plastic grocery bags in Amazon Fresh stores in Valencia, Spain. “That was a great application where paper was being used and it wasn’t meeting the requirements,” Jacobsen says. The grocery bags were being put in the fridge before being delivered to customers and because of the moisture, they were falling apart when people took them out. Switching to the plastic bags has “made it better for the folks that are delivering them and improved it all around.”

In the U.S., Jacobsen and his team have been testing out produce bags made from biopolyesters at some Whole Foods locations and at Amazon Fresh stores in the Seattle area. There, they have QR codes where customers can give feedback on the bags.

The Amazon lab collects that feedback, shares it with Novamont, and then they keep iterating on the design until it gets closer to what they want. “We learned that lettuce wilted faster [in the early bags],” says Jacobsen. “Is it the end of the world? Probably not, but to some customers, it’s not ideal.” Researchers at the lab could then take that feedback and reexamine the moisture barrier properties in the bags to see how that element could be adjusted.

Once these bags have been used, the goal is that they’re fed back into the recycling stream. To that end, Novamont is also conducting trials with one of Glacier’s AI models to ensure that the bags can be properly sorted once they reach a MRF. And then, of course, the ideal is that EsterCycle would be able to chemically break down the bags to be fed back into Novamont’s production system.

Designing a better recycling system—no matter who’s in the White House

Many of these developments are still years from being widely used in the market. That would seem compounded by the fact that the Trump administration appears actively hostile toward anything that benefits the environment and is cutting funding and staffing at research institutions across the country. (Just last week, 114 people were fired from NREL as part of massive cuts to the Department of Energy.)

Jacobsen admitted that it’s a bit of “a wait-and-see period,” and notes that while their funding isn’t necessarily dependent on the government, they do partner with government labs “where there’s an opportunity to accelerate progress.” He hopes that will continue to be possible over the next four years.

The Glacier team, meanwhile, is cautiously optimistic about what Trump means for their business. “Recycling in the waste industry as a whole tends to be extremely bipartisan,” says Glacier’s Hu-Thrams. “Whether you’re thinking about recycling from a climate crisis mitigation angle, or an onshoring and workforce development and job creation angle, there’s so many reasons why advancing recycling infrastructure and recycling efficiency is a really, really good thing to do for our society.”

Much of this work is also done at the state and local level, where decisions are more insulated from Trump’s rhetoric and slapdash executive orders. That’s where Jacobsen hopes to make the most progress, noting that cities like Seattle, San Francisco, and Denver are interested in incorporating these products into their recycling infrastructure.

It can be a bit jarring to try to square the innovations coming out of Jacobson’s team—and the genuine passion that they have for a fossil-fuel-free supply chain—with Amazon’s position as the largest online seller of stuff in the U.S. But our addiction to consumption—and Amazon’s commitment to fulfilling it—means that this cycle is unlikely to end anytime soon. Ensuring that it’s not wrapped in plastic made from fossil fuels is a big deal. And if they’re successful at transforming food packaging, it has implications far beyond just what we eat.

![[The AI Show Episode 156]: AI Answers - Data Privacy, AI Roadmaps, Regulated Industries, Selling AI to the C-Suite & Change Management](https://www.marketingaiinstitute.com/hubfs/ep%20156%20cover.png)

![[The AI Show Episode 155]: The New Jobs AI Will Create, Amazon CEO: AI Will Cut Jobs, Your Brain on ChatGPT, Possible OpenAI-Microsoft Breakup & Veo 3 IP Issues](https://www.marketingaiinstitute.com/hubfs/ep%20155%20cover.png)

.jpg?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

_Michael_Burrell_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)