"How Renting Industrial Equipment Can Improve Workflow Efficiency in Construction and Logistics Projects"

How Renting Industrial Equipment Can Improve Workflow Efficiency in Construction and Logistics Projects When managing a construction site or a logistics warehouse, productivity and cost-efficiency are always at the forefront. While many companies focus on hiring qualified labor and improving project timelines, one often overlooked area is equipment procurement strategy. In this article, we’ll explore how renting industrial equipment instead of purchasing it can streamline operations and reduce both financial and logistical overhead. Why Renting Equipment Is a Smart Move Many project managers and technical teams still rely on buying equipment that is only used occasionally. However, this traditional model leads to: High upfront investment Continuous maintenance costs Equipment depreciation Space problems for storage On the other hand, renting offers a more flexible and scalable alternative, especially for temporary projects or variable workloads. Key Equipment Categories to Rent Below are some of the most commonly rented equipment types in construction and logistics: 1. Aerial Work Platforms (AWPs) These platforms are essential for safe work at height. Depending on the task, you can rent: Scissor lifts Articulating boom lifts Telescopic platforms Crawler platforms Each type is suited for specific site conditions and elevation needs. 2. Forklifts and Material Handling Equipment Forklifts are crucial for moving heavy loads in warehouses and construction environments. Common types include: Diesel forklifts Electric forklifts Reach trucks Pallet stackers Instead of investing in multiple machines, renting provides access to exactly what is needed for the job at hand. 3. Auxiliary Equipment and Tools Additional tools such as generators, pallet jacks, compressors, and scaffolding are often required to support the core project tasks. Renting this secondary equipment ensures minimal idle inventory. Real-Life Case: Small Construction Company in Spain A small company working on mid-scale construction projects in Valencia, Spain, improved its operational efficiency by switching to an equipment rental model. They outsourced all their material handling and elevated work platforms through a local provider, significantly cutting costs and reducing idle time for tools.

How Renting Industrial Equipment Can Improve Workflow Efficiency in Construction and Logistics Projects

When managing a construction site or a logistics warehouse, productivity and cost-efficiency are always at the forefront. While many companies focus on hiring qualified labor and improving project timelines, one often overlooked area is equipment procurement strategy.

In this article, we’ll explore how renting industrial equipment instead of purchasing it can streamline operations and reduce both financial and logistical overhead.

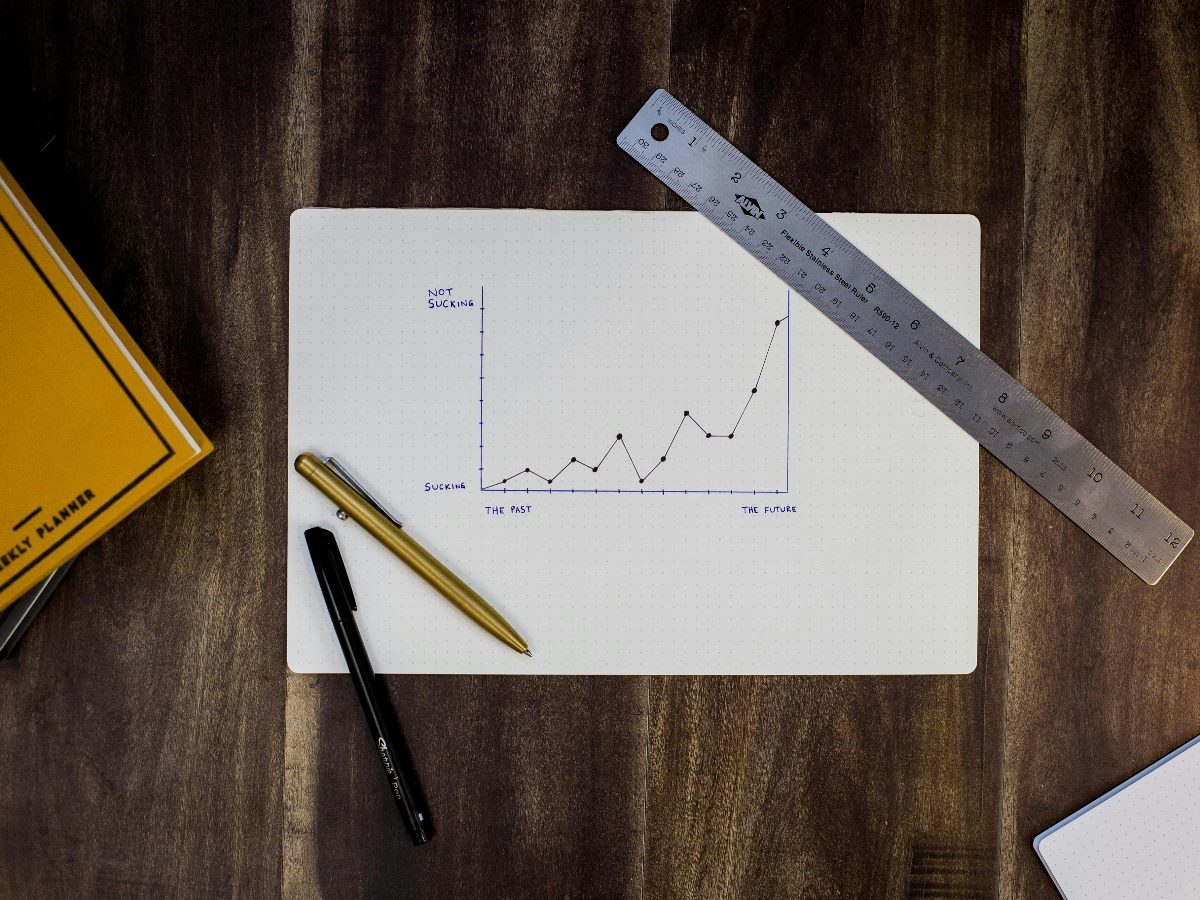

Why Renting Equipment Is a Smart Move

Many project managers and technical teams still rely on buying equipment that is only used occasionally. However, this traditional model leads to:

- High upfront investment

- Continuous maintenance costs

- Equipment depreciation

- Space problems for storage

On the other hand, renting offers a more flexible and scalable alternative, especially for temporary projects or variable workloads.

Key Equipment Categories to Rent

Below are some of the most commonly rented equipment types in construction and logistics:

1. Aerial Work Platforms (AWPs)

These platforms are essential for safe work at height. Depending on the task, you can rent:

- Scissor lifts

- Articulating boom lifts

- Telescopic platforms

- Crawler platforms

Each type is suited for specific site conditions and elevation needs.

2. Forklifts and Material Handling Equipment

Forklifts are crucial for moving heavy loads in warehouses and construction environments. Common types include:

- Diesel forklifts

- Electric forklifts

- Reach trucks

- Pallet stackers

Instead of investing in multiple machines, renting provides access to exactly what is needed for the job at hand.

3. Auxiliary Equipment and Tools

Additional tools such as generators, pallet jacks, compressors, and scaffolding are often required to support the core project tasks. Renting this secondary equipment ensures minimal idle inventory.

Real-Life Case: Small Construction Company in Spain

A small company working on mid-scale construction projects in Valencia, Spain, improved its operational efficiency by switching to an equipment rental model.

They outsourced all their material handling and elevated work platforms through a local provider, significantly cutting costs and reducing idle time for tools.

![[The AI Show Episode 143]: ChatGPT Revenue Surge, New AGI Timelines, Amazon’s AI Agent, Claude for Education, Model Context Protocol & LLMs Pass the Turing Test](https://www.marketingaiinstitute.com/hubfs/ep%20143%20cover.png)

-11.11.2024-4-49-screenshot.png?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

.png?#)

![Apple Debuts Official Trailer for 'Murderbot' [Video]](https://www.iclarified.com/images/news/96972/96972/96972-640.jpg)

![Alleged Case for Rumored iPhone 17 Pro Surfaces Online [Image]](https://www.iclarified.com/images/news/96969/96969/96969-640.jpg)

![Apple Rushes Five Planes of iPhones to US Ahead of New Tariffs [Report]](https://www.iclarified.com/images/news/96967/96967/96967-640.jpg)