Transforming Paper Production - How O3ai Cut OEE Losses by 25%

How O3ai transformed quality and maintenance results in a paper factory In the fiercely competitive paper production industry, efficiency and quality control are paramount. Obeikan Paper Industries, a major player producing 220,000 tons of paper and cardboard annually, faced some key challenges. O3ai's smart factory solution turned things around, leading to improved efficiency in maintenance and quality management. Challenges in Traditional Paper Manufacturing Before O3ai, Obeikan grappled with two primary issues: ● quality control – monitoring was manual, periodic, and couldn't provide real-time feedback, leading to delayed responses to production faults. ● maintenance efficiency – bogged down by manual planning and inefficient work order management systems, which contributed to missed OEE targets. O3ai's Technological Intervention O3ai implemented its platform alongside IIoT tech across one of Obeikan's paper factories. It transformed key areas: ● Quality Management O3ai automated and centralized quality control. This enabled real-time monitoring and faster response to quality issues. Overall, the number of rejects was reduced and overall product quality improved. ● Autonomous Maintenance Maintenance workflows were streamlined and made more proactive with automated maintenance requests. This reduced the processing time of work orders. Impressive Results in Quality Management & Maintenance O3ai made a big impact on operations: ● 16% Reduction in NCRs Real-time quality monitoring allowed for immediate corrections. ● 57% Reduction in Work Order Processing Time Quicker responses to maintenance issues led to boosted uptime. ● 25% Cut in OEE Losses Enhanced maintenance and quality control led to fewer production interruptions, directly boosting OEE scores. The Future of Paper Production with O3ai The potential of smart factory technology and AI is incredible. Automating and streamlining key processes and enabling real-time data analysis will transform any factory. As industries worldwide push towards higher levels of sustainability and efficiency, embracing technologies like those offered by O3ai will help them get there.

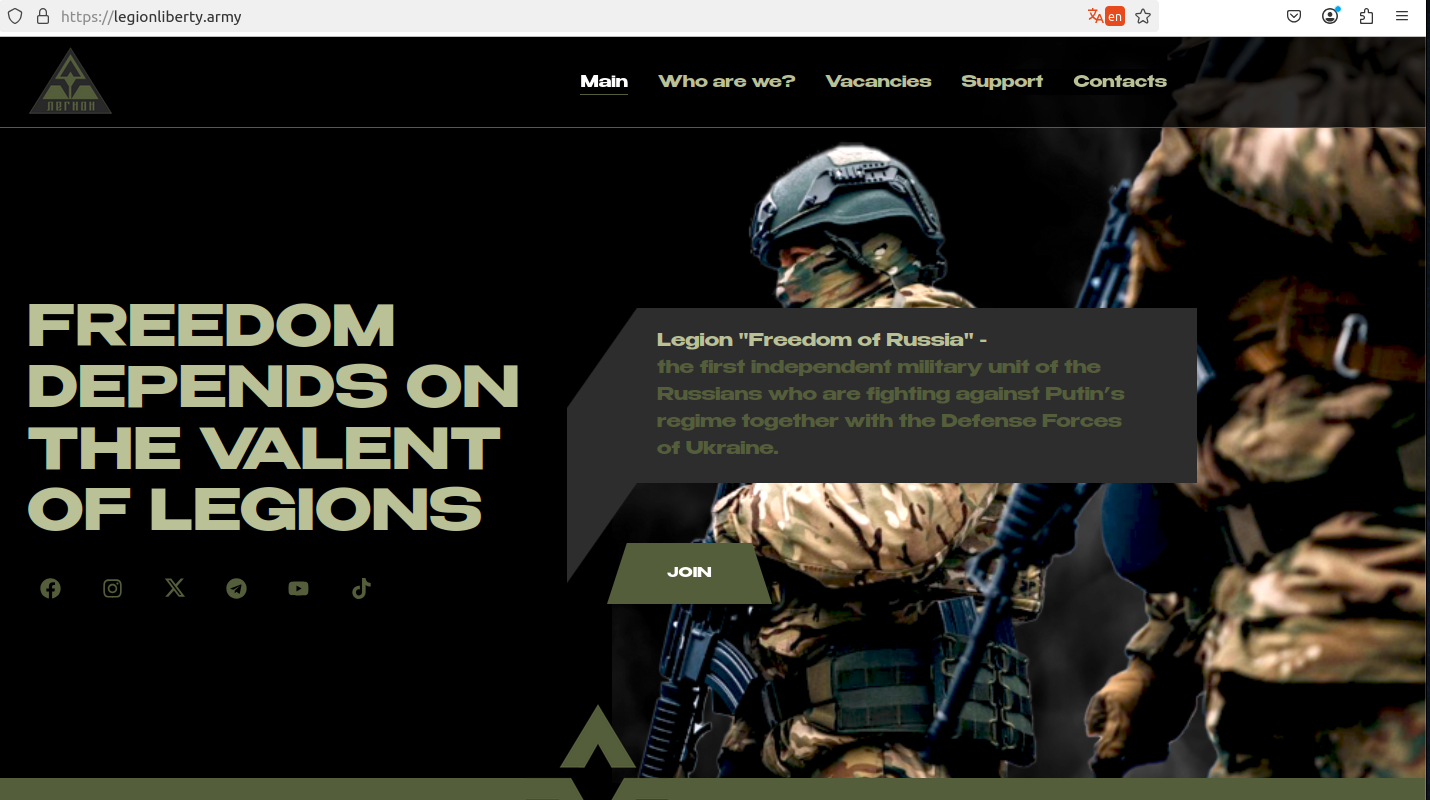

How O3ai transformed quality and maintenance results in a paper factory

In the fiercely competitive paper production industry, efficiency and quality control are paramount.

Obeikan Paper Industries, a major player producing 220,000 tons of paper and cardboard annually, faced some key challenges.

O3ai's smart factory solution turned things around, leading to improved efficiency in maintenance and quality management.

Challenges in Traditional Paper Manufacturing

Before O3ai, Obeikan grappled with two primary issues:

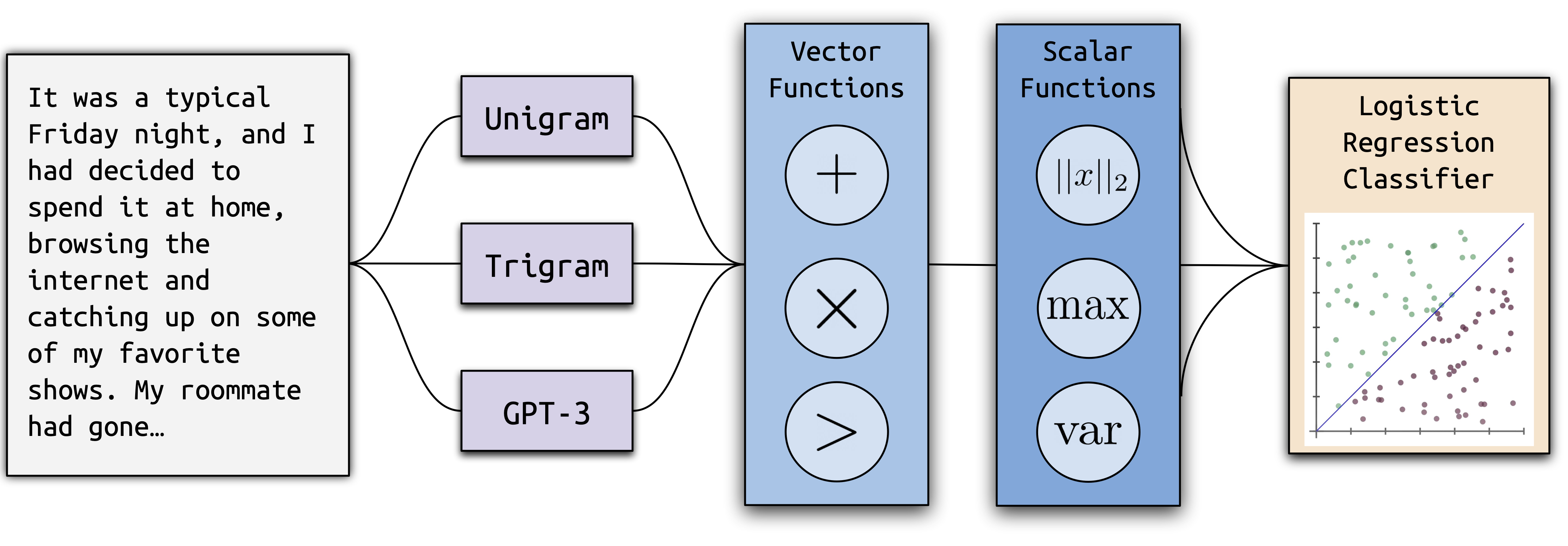

● quality control – monitoring was manual, periodic, and couldn't provide real-time feedback, leading to delayed responses to production faults.

● maintenance efficiency – bogged down by manual planning and inefficient work order management systems, which contributed to missed OEE targets.

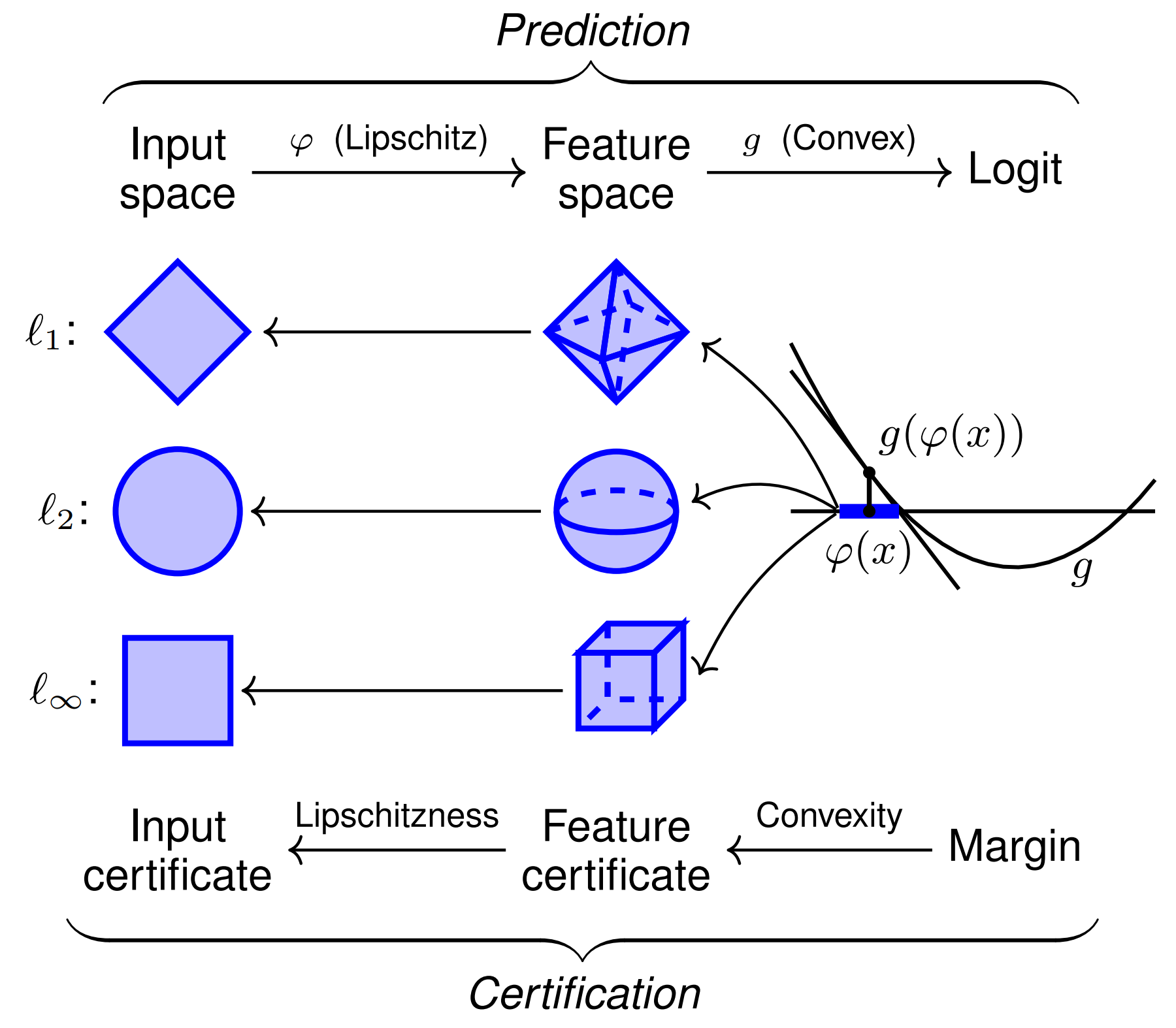

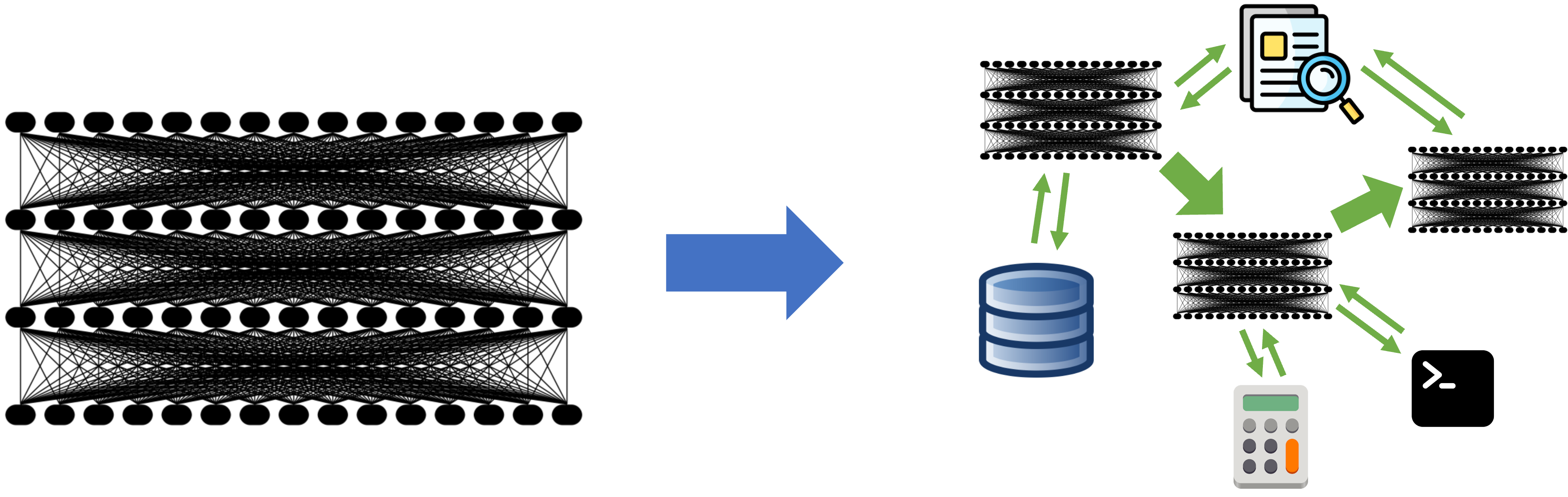

O3ai's Technological Intervention

O3ai implemented its platform alongside IIoT tech across one of Obeikan's paper factories. It transformed key areas:

● Quality Management

O3ai automated and centralized quality control. This enabled real-time monitoring and faster response to quality issues. Overall, the number of rejects was reduced and overall product quality improved.

● Autonomous Maintenance

Maintenance workflows were streamlined and made more proactive with automated maintenance requests. This reduced the processing time of work orders.

Impressive Results in Quality Management & Maintenance

O3ai made a big impact on operations:

● 16% Reduction in NCRs

Real-time quality monitoring allowed for immediate corrections.

● 57% Reduction in Work Order Processing Time

Quicker responses to maintenance issues led to boosted uptime.

● 25% Cut in OEE Losses

Enhanced maintenance and quality control led to fewer production interruptions, directly boosting OEE scores.

The Future of Paper Production with O3ai

The potential of smart factory technology and AI is incredible. Automating and streamlining key processes and enabling real-time data analysis will transform any factory.

As industries worldwide push towards higher levels of sustainability and efficiency, embracing technologies like those offered by O3ai will help them get there.

![[The AI Show Episode 142]: ChatGPT’s New Image Generator, Studio Ghibli Craze and Backlash, Gemini 2.5, OpenAI Academy, 4o Updates, Vibe Marketing & xAI Acquires X](https://www.marketingaiinstitute.com/hubfs/ep%20142%20cover.png)

![[DEALS] The Premium Learn to Code Certification Bundle (97% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

![From drop-out to software architect with Jason Lengstorf [Podcast #167]](https://cdn.hashnode.com/res/hashnode/image/upload/v1743796461357/f3d19cd7-e6f5-4d7c-8bfc-eb974bc8da68.png?#)

.png?#)

_Christophe_Coat_Alamy.jpg?#)

.webp?#)

![Apple Considers Delaying Smart Home Hub Until 2026 [Gurman]](https://www.iclarified.com/images/news/96946/96946/96946-640.jpg)

![iPhone 17 Pro Won't Feature Two-Toned Back [Gurman]](https://www.iclarified.com/images/news/96944/96944/96944-640.jpg)

![Tariffs Threaten Apple's $999 iPhone Price Point in the U.S. [Gurman]](https://www.iclarified.com/images/news/96943/96943/96943-640.jpg)