Innovations in Modular Engineering Solutions: Revolutionizing the Oil and Gas Sector

Modular engineering is transforming the oil and gas sector with faster, safer, and more cost-effective construction methods. This article explores cutting-edge trends such as automation, sustainability, and digitalization, and highlights the pivotal role of industrial engineering in optimizing modular systems. Discover how these innovations are improving project outcomes, reducing environmental impact, and shaping the future of energy infrastructure.

In the ever-evolving oil and gas industry, modular engineering solutions are at the forefront of innovation, offering cost-effective, flexible, and efficient alternatives to traditional construction methods. As the demand for energy continues to grow, the need for innovative technologies that can streamline operations and reduce environmental impact has become increasingly crucial. At the heart of this transformation lies industrial engineering, which plays a pivotal role in optimizing modular systems, processes, and resources. In this article, we will explore the latest trends and technologies in modular engineering solutions—and how industrial engineering is driving efficiency and sustainability in the oil and gas sector.

The Rise of Modular Construction

Modular construction involves prefabricating components of a project in a controlled environment, such as a factory, and then transporting and assembling them on-site. This approach has gained significant traction in the oil and gas industry due to its numerous benefits, including:

Improved Quality Control

By fabricating components in a controlled environment, modular construction ensures consistent quality and reduces the risk of defects. Industrial engineering techniques such as Six Sigma and statistical process control further enhance this quality by identifying and eliminating variability.

Reduced Construction Time

Modular construction allows for parallel fabrication and on-site assembly, significantly reducing project timelines. Industrial engineers streamline these workflows by optimizing supply chains, resource allocation, and assembly line operations.

Cost Savings

Modular construction can lead to cost savings through reduced labor costs, efficient material usage, and minimized on-site waste. Cost-benefit analysis and lean manufacturing principles, staples of industrial engineering, are key to identifying areas for savings.

Enhanced Safety

By shifting a substantial portion of the construction process to a controlled environment, modular construction reduces the risks associated with on-site work, such as exposure to harsh weather conditions and potential accidents. Industrial engineers design workflows and systems to improve worker safety and ergonomics.

Emerging Trends in Modular Engineering Solutions

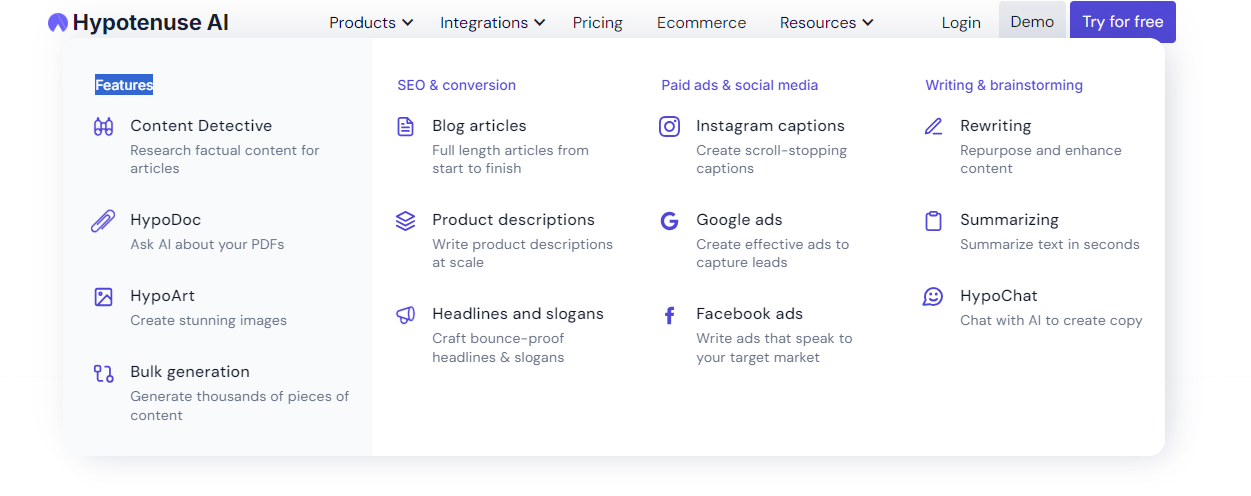

Automation and Robotics

The integration of automation and robotics in modular fabrication is revolutionizing the industry. Advanced technologies, such as BIM (Building Information Modeling) and 3D printing, are streamlining the design and fabrication process, reducing errors and improving efficiency. Industrial engineering plays a critical role in integrating these technologies into manufacturing systems and optimizing production lines.

Integrated Modular Solutions

Modular engineering solutions are becoming increasingly integrated, combining multiple systems and components into a single, pre-assembled unit. This approach reduces the number of connections and interfaces required on-site. Industrial engineers contribute by developing systems integration strategies that reduce complexity and maximize performance.

Sustainability and Environmental Considerations

As the industry focuses more on sustainability and environmental stewardship, modular engineering solutions are being designed with a greater emphasis on reducing the carbon footprint. This includes the use of renewable energy sources, such as solar and wind power, to power modular facilities and the implementation of eco-friendly materials and processes. Industrial engineers conduct life cycle assessments and energy optimization analyses to ensure that these solutions are both effective and sustainable.

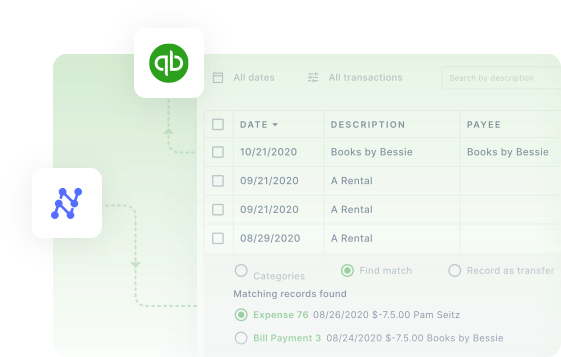

Digitalization and Smart Technologies

The adoption of digital technologies, including smart grids and IoT (Internet of Things) solutions, is transforming how energy is managed and distributed in modular engineering projects. These technologies enable real-time monitoring and optimization of energy systems. Industrial engineering tools such as systems modeling, predictive maintenance algorithms, and data analytics are crucial in managing this digital transformation.

Customization and Flexibility

Modular engineering solutions are becoming increasingly customizable, allowing for easy adaptation to specific project requirements. This flexibility is crucial in the oil and gas industry, where each project presents unique challenges and constraints. Industrial engineers develop modular design frameworks and configuration tools that allow rapid adaptation without compromising performance or safety.

Benefits of Modular Engineering Solutions

Reduced Project Risks

By shifting construction activities to a controlled environment, modular engineering solutions minimize the risks associated with on-site work, such as weather delays and safety hazards. Risk analysis methods from industrial engineering further support this reduction by proactively identifying potential bottlenecks or failures.

Improved Project Outcomes

Modular engineering solutions can lead to better project outcomes through enhanced quality control, reduced construction times, and cost savings. These outcomes are often the result of industrial engineering principles applied to process design and continuous improvement.

Increased Efficiency

Modular engineering solutions optimize operational efficiency by streamlining processes, reducing waste, and enabling real-time monitoring and optimization of energy systems. Industrial engineers use tools like value stream mapping and simulation modeling to drive efficiency at every stage.

Adaptability to Changing Needs

The flexibility of modular engineering solutions allows for easy adaptation to changing project requirements and market conditions, ensuring long-term viability and competitiveness. Industrial engineering supports this adaptability through dynamic planning models and scenario-based decision-making.

Conclusion

As the oil and gas industry continues to evolve, modular engineering solutions are poised to play a crucial role in driving innovation and efficiency. By integrating the core principles of industrial engineering, companies can unlock the full potential of modular construction and position themselves for success in an increasingly competitive and sustainable market. From enhanced quality

control to improved environmental stewardship and resource optimization, industrial engineering is the backbone that supports and advances the transformative power of modular solutions in the oil and gas sector.

![[The AI Show Episode 151]: Anthropic CEO: AI Will Destroy 50% of Entry-Level Jobs, Veo 3’s Scary Lifelike Videos, Meta Aims to Fully Automate Ads & Perplexity’s Burning Cash](https://www.marketingaiinstitute.com/hubfs/ep%20151%20cover.png)

![[DEALS] FileJump 2TB Cloud Storage: Lifetime Subscription (85% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

![From electrical engineering student to CTO with Hitesh Choudhary [Podcast #175]](https://cdn.hashnode.com/res/hashnode/image/upload/v1749158756824/3996a2ad-53e5-4a8f-ab97-2c77a6f66ba3.png?#)

![Apple Shares Official Trailer for 'The Wild Ones' [Video]](https://www.iclarified.com/images/news/97515/97515/97515-640.jpg)