Unlocking $100M+ in Predictive Maintenance Value Through Edge Infrastructure

Industrial companies are sitting on a predictive maintenance goldmine worth hundreds of millions in potential savings, yet most struggle to expand beyond successful pilots. The pattern is distressingly familiar: A team implements predictive maintenance for a critical asset, proves the value with impressive projected ROI metrics, then hits an insurmountable wall when trying to scale across […] The post Unlocking $100M+ in Predictive Maintenance Value Through Edge Infrastructure appeared first on Unite.AI.

Industrial companies are sitting on a predictive maintenance goldmine worth hundreds of millions in potential savings, yet most struggle to expand beyond successful pilots. The pattern is distressingly familiar: A team implements predictive maintenance for a critical asset, proves the value with impressive projected ROI metrics, then hits an insurmountable wall when trying to scale across multiple production lines, plants, or regions. What separates the companies achieving enterprise-wide success from those stuck in perpetual pilot mode? The answer lies not in better algorithms or more sensors, but in the underlying infrastructure connecting them.

The Scaling Barrier

While the industry focuses on sophisticated AI algorithms and sensor technology, the true challenge of predictive maintenance is decidedly more practical: scaling. The typical journey begins with a single high-value asset—a compressor, turbine, or piece of production-critical equipment—with substantial costs for unplanned. Companies outfit this equipment with sensors, develop analytics models, and connect it to visualization platforms, often seeing 30% reduction in unplanned downtime. Yet when attempting to replicate this success across multiple assets or facilities, they encounter a web of disparate hardware, inconsistent connectivity, and integration nightmares that bring expansion to a standstill.

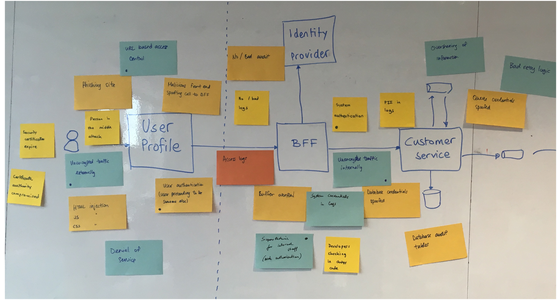

Many organizations approach predictive maintenance as a software problem, purchasing a solution and expecting immediate results. But the reality is more complex. Different plants have different equipment vintages, network architectures, and operational technologies. Due to infrastructure differences, the solution required for a compressor in Plant A might require significant customization for an identical compressor in Plant B. Without a standardized foundation to handle this diversity, companies recreate their solutions for each asset and location, multiplying costs and complexity.

The result? Islands of predictive maintenance excellence in a sea of traditional maintenance practices, with the promised enterprise-wide transformation perpetually out of reach.

The Data Dilemma

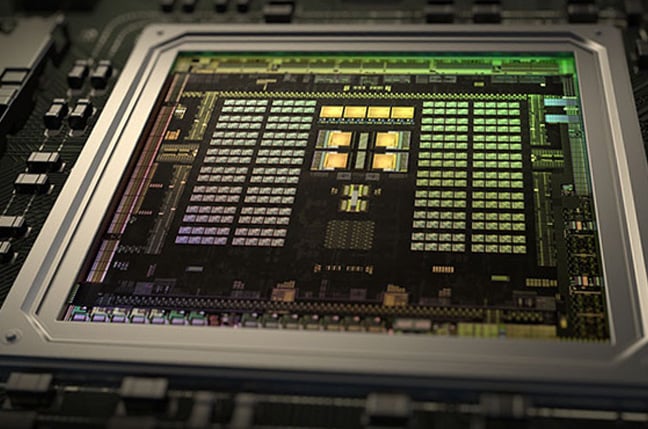

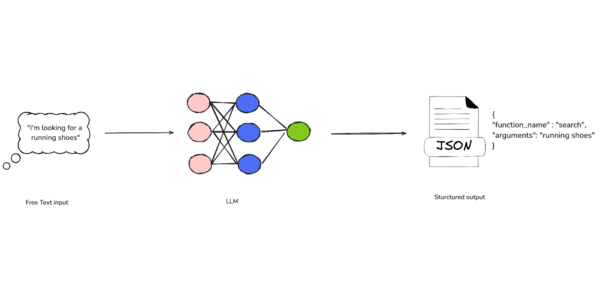

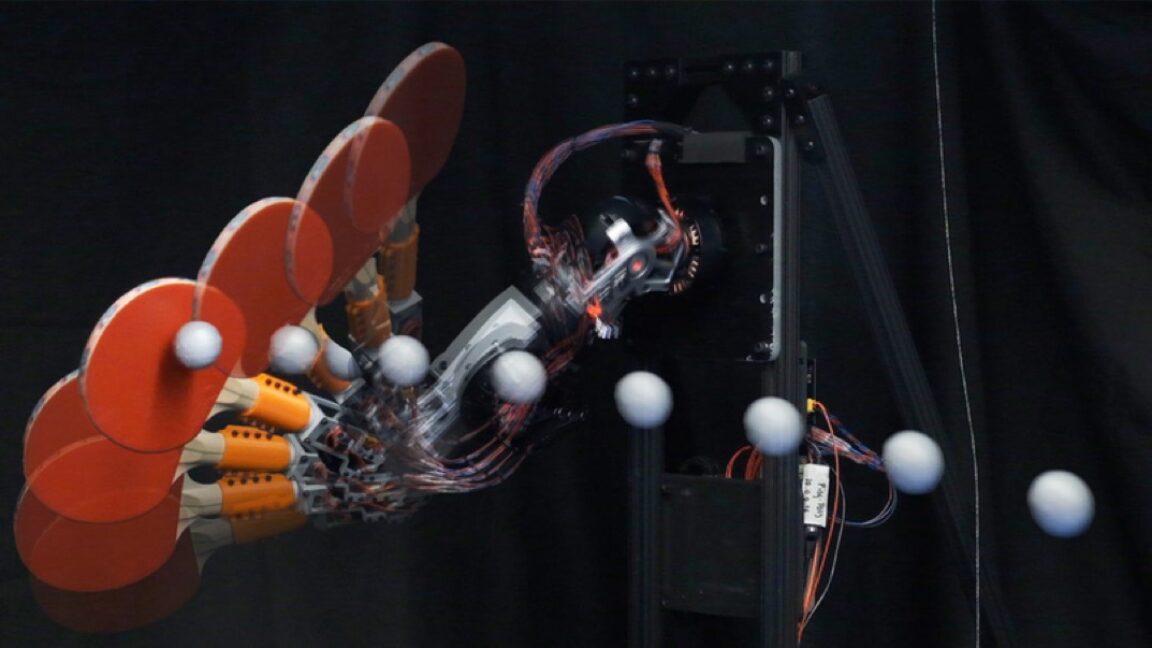

The proliferation of industrial sensors creates a data challenge of staggering proportions. A single industrial pump might generate 5GB of vibration data daily—multiply that across hundreds of assets and multiple plants, and the bandwidth and cloud computing costs become prohibitive. The traditional approach of sending all data to centralized cloud platforms creates latency issues that render real-time analytics impossible in time-critical applications.

Consider oil and gas operations where 20-30 minutes' warning of compressor failure can prevent catastrophic cascading failures—cloud latency simply isn't an option. In manufacturing, where unplanned downtime costs average $260,000 per hour, every minute of latency represents thousands in potential losses. This “data gravity” challenge requires processing at the source, filtering what travels to the cloud, and maintaining consistent analysis capabilities across diverse operational environments.

Successful implementations recognize that edge computing isn't just about bandwidth savings—it's about creating the real-time intelligence layer that makes predictive maintenance actionable when and where it matters most.

The Integration Imperative

Predictive maintenance delivers its full value only when integrated with enterprise systems. When a predictive model identifies an impending failure, that intelligence must flow seamlessly into maintenance management systems to generate work orders, ERP systems to order parts, and production planning systems to minimize disruption. Without this integration, even the most accurate predictions remain academic exercises rather than operational tools.

The integration challenge multiplies exponentially across facilities with different legacy systems, protocols, and operational technologies. What works for connecting to a maintenance management system in one plant may require complete reconfiguration in another. Companies that successfully scale predictive maintenance build a consistent integration layer that bridges these gaps while respecting the unique requirements of each facility.

The most advanced organizations are taking this further, creating automated workflows that predict failures and trigger appropriate responses without human intervention. These include scheduling maintenance during planned downtime, ordering parts based on inventory levels, and notifying relevant personnel. This level of integration transforms predictive maintenance from a reactive tool into a proactive system that optimizes overall operations.

The ROI Acceleration

The economics of predictive maintenance follow a clear pattern: high initial investment with exponential returns at scale. In one example, a single high-value asset delivered $300,000 in annual savings through reduced downtime and maintenance costs. If you scale that across 15 similar assets in a plant, you're saving over $5 million. Extend to 10 plants, and the potential reaches more than $52 million.

Yet many companies struggle to move beyond those first critical assets because they didn't design with scale in mind. The cost of implementing predictive maintenance for the first asset is dominated by hardware, connectivity, model development, and integration costs. Without a standardized edge infrastructure, these costs are repeated for each new implementation rather than leveraged across deployments.

Successful companies build standardized edge infrastructure that creates a repeatable deployment model, dramatically reducing the incremental cost and complexity of each new asset. This approach transforms predictive maintenance from a series of one-off projects into a systematic enterprise capability with accelerating returns.

The Competitive Divide

The predictive maintenance maturity curve is rapidly separating industrial companies into two categories: those leveraging standardized edge infrastructure to achieve enterprise-wide transformation, and those trapped in an endless cycle of successful pilots and failed scaling attempts. With average downtime costs going from hundreds of thousands to more than a million dollars per hour, the cost of inaction grows every day.

The companies succeeding at scale aren't necessarily those with the most advanced algorithms or sensors—they're the ones that recognized early that edge infrastructure is the foundation that makes industrial intelligence possible at enterprise scale. As we enter an era where predictive is giving way to prescriptive maintenance, building this foundation isn't just about catching up—it's about ensuring your company has the infrastructure in place for the next wave of industrial intelligence.

The time to address the missing link in predictive maintenance is now. The technology is mature, the ROI is proven, and the competitive advantage for adopters is substantial. The only question remaining is whether your organization will be among those reaping the benefits of enterprise-wide predictive maintenance or still struggling to scale beyond pilots.

The post Unlocking $100M+ in Predictive Maintenance Value Through Edge Infrastructure appeared first on Unite.AI.

![[The AI Show Episode 150]: AI Answers: AI Roadmaps, Which Tools to Use, Making the Case for AI, Training, and Building GPTs](https://www.marketingaiinstitute.com/hubfs/ep%20150%20cover.png)

![[The AI Show Episode 149]: Google I/O, Claude 4, White Collar Jobs Automated in 5 Years, Jony Ive Joins OpenAI, and AI’s Impact on the Environment](https://www.marketingaiinstitute.com/hubfs/ep%20149%20cover.png)

![[FREE EBOOKS] Solutions Architect’s Handbook, The Embedded Linux Security Handbook & Four More Best Selling Titles](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

![How to Survive in Tech When Everything's Changing w/ 21-year Veteran Dev Joe Attardi [Podcast #174]](https://cdn.hashnode.com/res/hashnode/image/upload/v1748483423794/0848ad8d-1381-474f-94ea-a196ad4723a4.png?#)

_ArtemisDiana_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

![Sonos Father's Day Sale: Save Up to 26% on Arc Ultra, Ace, Move 2, and More [Deal]](https://www.iclarified.com/images/news/97469/97469/97469-640.jpg)

![Apple 15-inch M4 MacBook Air On Sale for $1023.86 [Lowest Price Ever]](https://www.iclarified.com/images/news/97468/97468/97468-640.jpg)