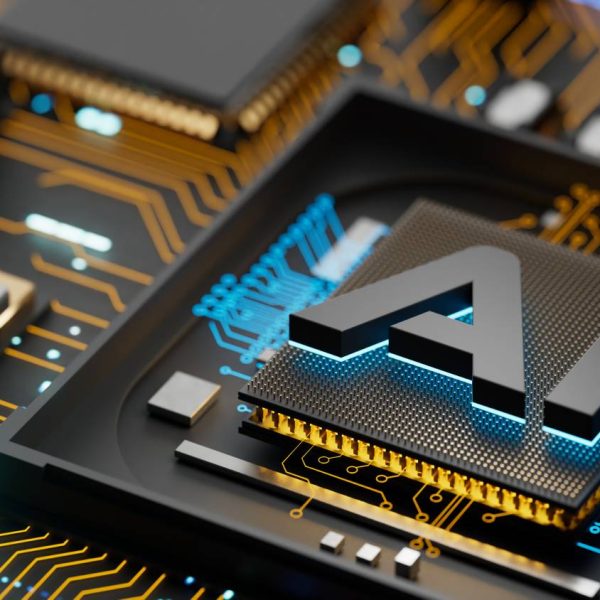

Aluminum Nitride Ceramic Resistors: High Performance for High Frequency and High Power Applications

In today's fast-paced technological landscape, the demand for high-performance electronic components continues to grow. Aluminum nitride (AlN) ceramic resistors stand out as a premier solution for applications requiring exceptional thermal management, high power handling, and reliability in high-frequency environments. Here's why these resistors are the ideal choice for your next project: Exceptional Thermal Performance Aluminum nitride ceramic resistors are renowned for their high thermal conductivity, ranging from 170 to 220 W/m·K. This makes them one of the best ceramic materials for heat dissipation, outperforming traditional alumina substrates by up to 9.5 times. Combined with their low thermal expansion coefficient, which closely matches that of silicon, these resistors ensure stable performance even under extreme temperature variations. High Power Handling and Electrical Insulation These resistors are designed to handle high power levels, with some models offering up to 6 watts of power dissipation in compact packages like 2512. Their excellent electrical insulation properties make them ideal for applications where safety and reliability are critical. Additionally, aluminum nitride substrates provide superior compatibility with high-frequency circuits, ensuring minimal parasitic capacitance and inductance. Applications Across Industries Aluminum nitride ceramic resistors excel in a variety of demanding applications: High-frequency circuits: Ideal for telecommunications and RF applications, these resistors operate efficiently at frequencies up to 40 GHz. High-power energy absorption: Perfect for power supplies, braking systems, and switching applications where efficient heat dissipation is crucial. Precision environments: Their stability and low temperature coefficient (as low as ±25 ppm/°C) make them suitable for precision thin-film applications. Why Choose Aluminum Nitride? Superior heat dissipation: Efficient thermal management ensures longer component lifespan and reduced failure rates. High mechanical strength: Robust construction withstands harsh environmental conditions. Customizable solutions: Through innovative thick-film printing processes, resistors can be tailored to meet specific power and performance requirements. Conclusion Aluminum nitride ceramic resistors represent the pinnacle of high-performance electronic components. Their combination of high thermal conductivity, low thermal expansion, and excellent electrical insulation makes them indispensable for modern high-frequency and high-power applications. Whether you're designing for telecommunications, power electronics, or precision instrumentation, these resistors deliver unmatched reliability and efficiency. www.eak.sg Upgrade your designs today with aluminum nitride ceramic resistors—the future of high-performance electronics.

In today's fast-paced technological landscape, the demand for high-performance electronic components continues to grow. Aluminum nitride (AlN) ceramic resistors stand out as a premier solution for applications requiring exceptional thermal management, high power handling, and reliability in high-frequency environments. Here's why these resistors are the ideal choice for your next project:

Exceptional Thermal Performance

Exceptional Thermal Performance

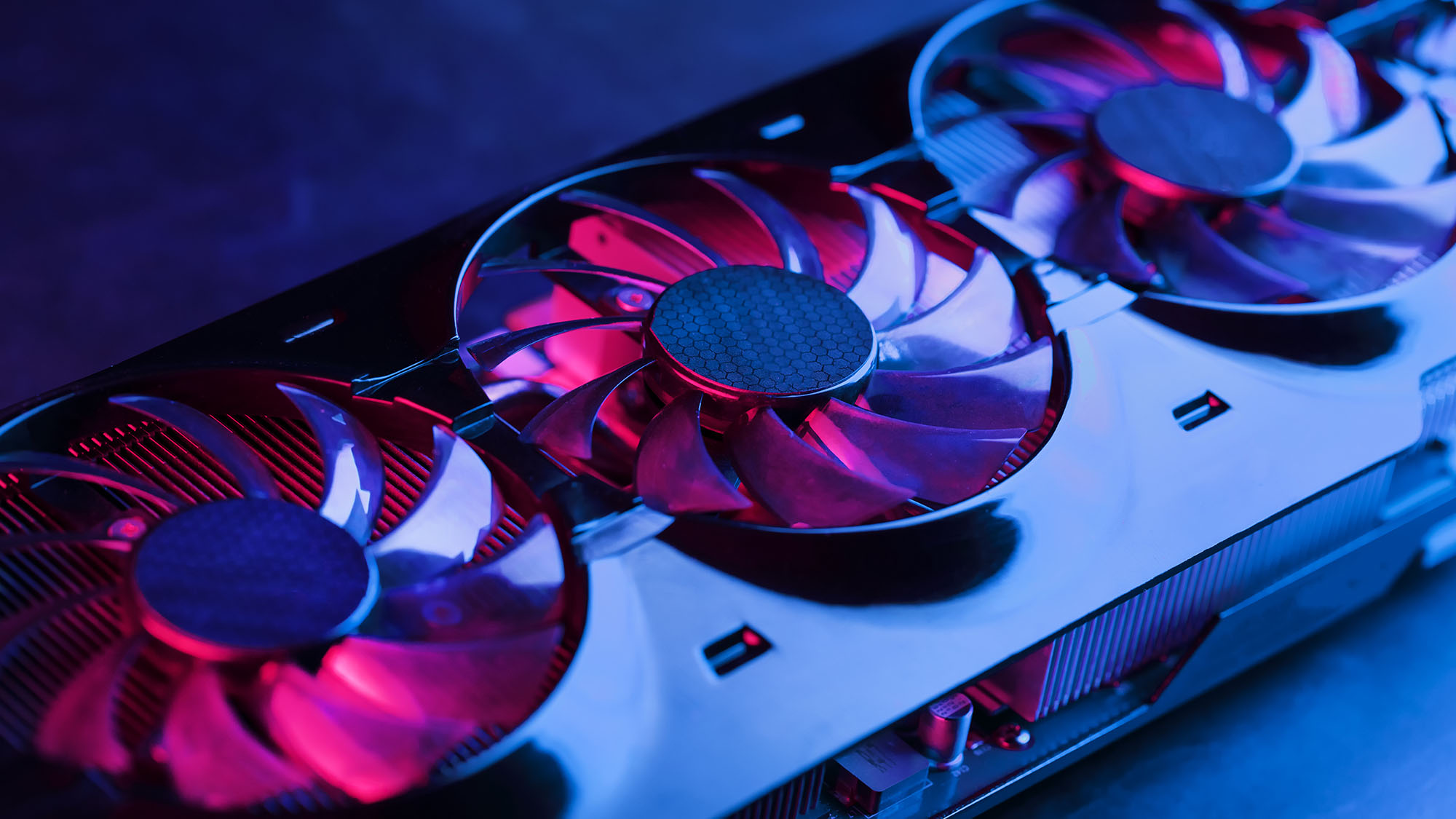

Aluminum nitride ceramic resistors are renowned for their high thermal conductivity, ranging from 170 to 220 W/m·K. This makes them one of the best ceramic materials for heat dissipation, outperforming traditional alumina substrates by up to 9.5 times. Combined with their low thermal expansion coefficient, which closely matches that of silicon, these resistors ensure stable performance even under extreme temperature variations.

High Power Handling and Electrical Insulation

These resistors are designed to handle high power levels, with some models offering up to 6 watts of power dissipation in compact packages like 2512. Their excellent electrical insulation properties make them ideal for applications where safety and reliability are critical. Additionally, aluminum nitride substrates provide superior compatibility with high-frequency circuits, ensuring minimal parasitic capacitance and inductance.

Applications Across Industries

Aluminum nitride ceramic resistors excel in a variety of demanding applications:

High-frequency circuits: Ideal for telecommunications and RF applications, these resistors operate efficiently at frequencies up to 40 GHz.

High-power energy absorption: Perfect for power supplies, braking systems, and switching applications where efficient heat dissipation is crucial.

Precision environments: Their stability and low temperature coefficient (as low as ±25 ppm/°C) make them suitable for precision thin-film applications.

Why Choose Aluminum Nitride?

Superior heat dissipation: Efficient thermal management ensures longer component lifespan and reduced failure rates.

High mechanical strength: Robust construction withstands harsh environmental conditions.

Customizable solutions: Through innovative thick-film printing processes, resistors can be tailored to meet specific power and performance requirements.

Conclusion

Aluminum nitride ceramic resistors represent the pinnacle of high-performance electronic components. Their combination of high thermal conductivity, low thermal expansion, and excellent electrical insulation makes them indispensable for modern high-frequency and high-power applications. Whether you're designing for telecommunications, power electronics, or precision instrumentation, these resistors deliver unmatched reliability and efficiency. www.eak.sg

Upgrade your designs today with aluminum nitride ceramic resistors—the future of high-performance electronics.

![[The AI Show Episode 143]: ChatGPT Revenue Surge, New AGI Timelines, Amazon’s AI Agent, Claude for Education, Model Context Protocol & LLMs Pass the Turing Test](https://www.marketingaiinstitute.com/hubfs/ep%20143%20cover.png)

.png?#)

.webp?#)

.webp?#)

.webp?#)

![[Fixed] Gemini app is failing to generate Audio Overviews](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/03/Gemini-Audio-Overview-cover.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![What’s new in Android’s April 2025 Google System Updates [U: 4/14]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/01/google-play-services-3.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Apple Seeds tvOS 18.5 Beta 2 to Developers [Download]](https://www.iclarified.com/images/news/97011/97011/97011-640.jpg)

![Apple Releases macOS Sequoia 15.5 Beta 2 to Developers [Download]](https://www.iclarified.com/images/news/97014/97014/97014-640.jpg)