How Microsoft shrunk its Surface devices

Microsoft has brought me inside the Surface hardware lab from time to time over the years, showing me how its engineers test the hinges and fabrics that go into its products. They're usually typical engineering demonstrations, but last month I was invited to Microsoft's headquarters in Redmond, Washington, to see how the company built its […]

Microsoft has brought me inside the Surface hardware lab from time to time over the years, showing me how its engineers test the hinges and fabrics that go into its products. They're usually typical engineering demonstrations, but last month I was invited to Microsoft's headquarters in Redmond, Washington, to see how the company built its two new smaller Surface Pro and Surface Laptop devices. And this time around, I was pleasantly surprised to be shown how Microsoft uses magnets, robots, drop tests, and smoke to perfect its laptop and tablet designs.

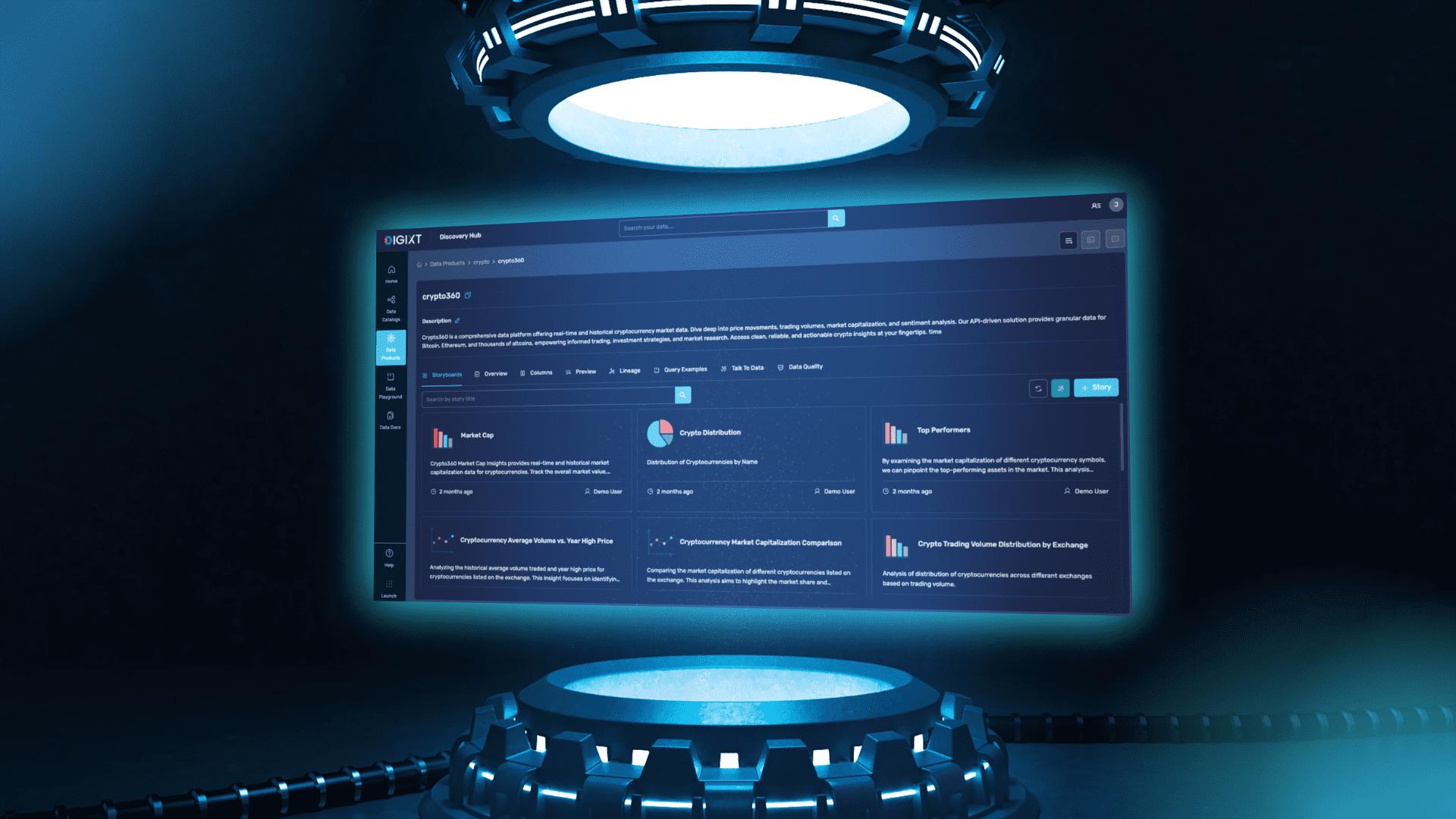

The first stop on the tour led me inside Microsoft's advanced prototype center, where Surface engineers are constantly creating prototypes to refine the fit and finish on a new product like the Surface Pro 12-inch. One of the new challenges for this device was getting the Surface Pen to attach to the rear of the tablet - and stay there.

Microsoft wanted the stylus to attach with one hand but still be tough enough to stay in place when you slide it into a backpack. Engineers designed different magnet combinations, then tested their effectiveness with machines that record the force and distance needed to remove the pen. The team the …

![[The AI Show Episode 146]: Rise of “AI-First” Companies, AI Job Disruption, GPT-4o Update Gets Rolled Back, How Big Consulting Firms Use AI, and Meta AI App](https://www.marketingaiinstitute.com/hubfs/ep%20146%20cover.png)

![Beats Studio Pro Wireless Headphones Now Just $169.95 - Save 51%! [Deal]](https://www.iclarified.com/images/news/97258/97258/97258-640.jpg)