How Supply Chain Management Software Drives Efficiency and Profit?

Discover how Supply Chain Management Software transforms business operations by streamlining workflows, cutting costs, and enhancing productivity. From real-time data to workforce wellness, this blog explores how the right technology can drive both efficiency and long-term profit for modern businesses.

In a highly competitive and globalized market, companies are under increasing pressure to streamline operations, reduce costs, and deliver faster—all while maintaining safety, quality, and employee well-being. One of the most powerful tools enabling this transformation is Supply Chain Management Software. From procurement to delivery, this software helps businesses optimize every step of their supply chain, resulting in improved efficiency and greater profitability.

What’s more, when integrated with solutions like Occupational Health & Safety Software, Employee Health Software, Quality Management Systems, and Occupational Health Services, it creates a holistic ecosystem where both operational excellence and workforce welfare are prioritized.

What Is Supply Chain Management Software?

Supply Chain Management Software refers to a suite of digital tools designed to manage and streamline supply chain activities, including sourcing, inventory management, logistics, order processing, and supplier relationships. Modern SCMS solutions provide real-time data, predictive analytics, automation, and integration capabilities that help businesses make smarter, faster decisions.

Core Functions of SCMS Include:

-

Inventory and warehouse management

-

Supplier and vendor coordination

-

Demand forecasting

-

Procurement automation

-

Logistics and transportation optimization

-

Risk assessment and compliance tracking

Efficiency Starts with Visibility and Automation

One of the main reasons companies adopt SCMS is the real-time visibility it offers. By providing a unified view of operations, the software enables businesses to monitor and manage every link in the supply chain. This eliminates bottlenecks, reduces duplication of efforts, and prevents costly errors such as overstocking or delayed shipments.

Automation Boosts Speed and Reduces Human Error

With automation, tasks such as order processing, invoice generation, shipment tracking, and inventory updates are handled faster and more accurately. This not only accelerates the workflow but also reduces reliance on manual labor, freeing staff to focus on higher-value tasks.

For example, a manufacturer using SCMS can automatically reorder raw materials when inventory drops below a defined threshold. This proactive approach prevents production delays and improves customer satisfaction.

Driving Profit Through Data-Driven Decisions

Another major benefit of Supply Chain Management Software is its ability to analyze historical and real-time data. This empowers businesses to:

-

Forecast demand more accurately

-

Optimize procurement and reduce material costs

-

Minimize waste and transportation expenses

-

Improve delivery timelines

When you have access to predictive analytics, you can respond swiftly to market changes, avoid disruptions, and negotiate better terms with suppliers. This data-centric approach ensures resources are used wisely, leading to higher profit margins.

Integration with Quality Management System

A Quality Management System ensures that products and services consistently meet customer expectations and regulatory standards. When integrated with SCMS, it enables companies to track quality metrics across the entire supply chain—from supplier performance to product delivery.

Benefits of Integration Include:

-

Real-time tracking of quality issues and non-conformances

-

Supplier audits and compliance management

-

Faster corrective and preventive actions

-

Reduced product recalls and rework costs

With QMS integration, companies not only maintain compliance but also uphold their reputation for delivering high-quality products—an essential factor in long-term profitability.

Promoting Health and Safety in the Supply Chain

Efficiency and profitability are not just about speed and cost—they also depend on maintaining a safe and healthy work environment. Occupational Health & Safety Software plays a crucial role in managing risks associated with supply chain operations, especially in manufacturing, logistics, and warehousing.

How It Supports Supply Chain Efficiency:

-

Tracks incidents and near-misses in real time

-

Identifies high-risk processes and recommends improvements

-

Ensures compliance with safety regulations

-

Automates training and safety audits

By reducing workplace accidents and promoting safety, businesses avoid costly downtime, fines, and reputational damage. This, in turn, contributes to both operational stability and profit.

Supporting Workforce Wellness with Employee Health Software

A resilient supply chain relies heavily on the health and well-being of its workforce. Employee Health Software helps companies monitor and manage employee wellness across supply chain functions.

Features typically include:

-

Health risk assessments

-

Vaccination and health check tracking

-

Stress and fatigue monitoring

-

Integration with Occupational Health Services

Healthy employees are more productive, take fewer sick days, and are less likely to cause delays or errors. Integrating this software into your supply chain ecosystem ensures that the workforce remains fit, engaged, and aligned with organizational goals.

Future Outlook: Smart Supply Chains and IoT

As businesses look to the future, the role of SCMS will continue to evolve with the adoption of technologies like:

-

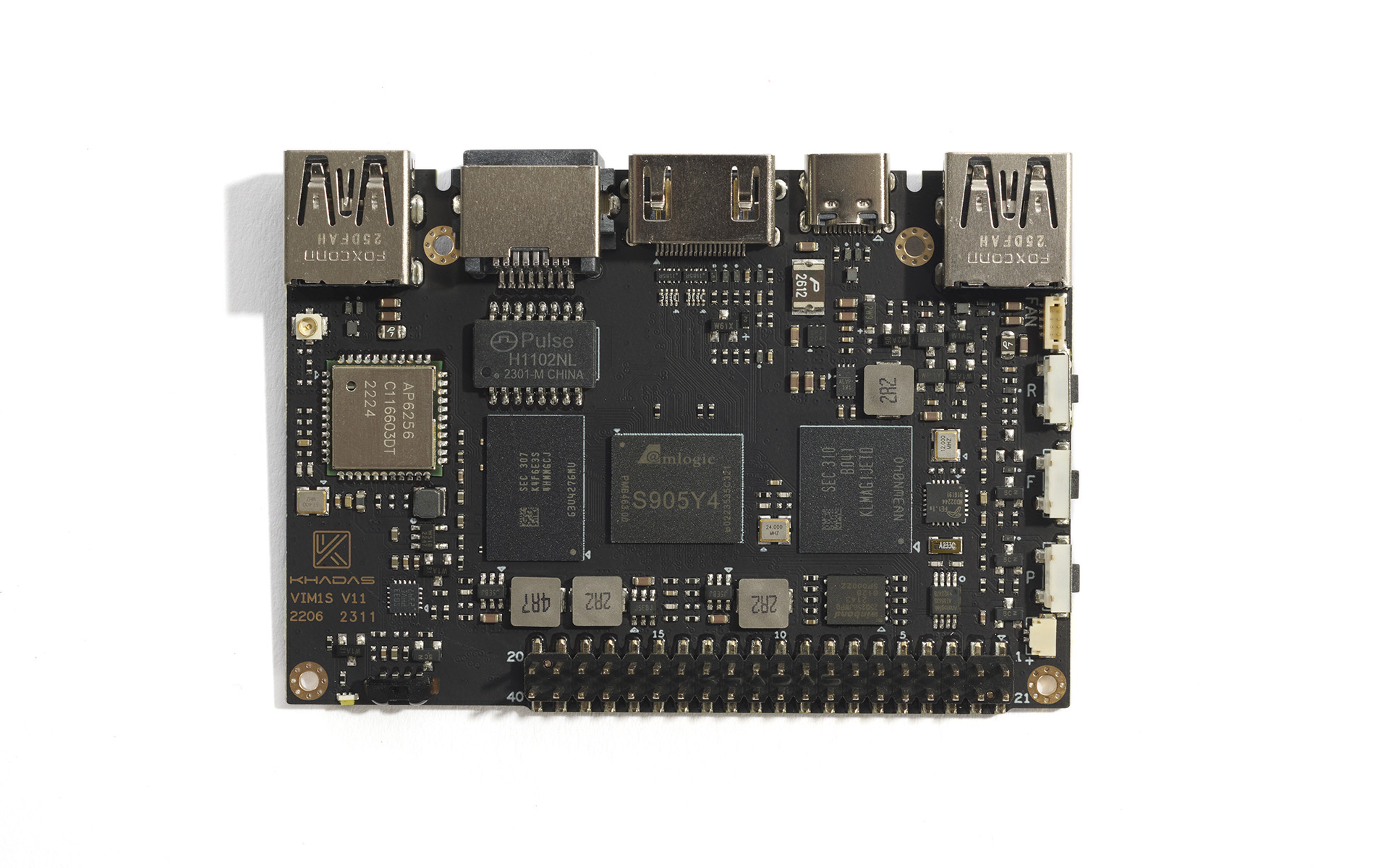

Internet of Things: Real-time asset tracking and environmental monitoring

-

AI and Machine Learning: Smarter demand forecasting and risk detection

-

Blockchain: Enhanced transparency and traceability

-

Cloud Integration: Centralized and scalable operations

Combined with a strong foundation in quality, health, and safety, these innovations will pave the way for smarter, more sustainable, and highly profitable supply chains.

Conclusion: It’s Time to Modernize

Efficiency and profit are no longer achieved by working harder they’re achieved by working smarter. Supply Chain Management Software, when integrated with tools like Occupational Health & Safety Software, Employee Health Software, and a Quality Management System, enables businesses to build agile, safe, and optimized supply chains that can adapt to any challenge.

Whether you're a manufacturer, distributor, or retailer, the message is clear: to stay competitive, invest in the right systems. Let technology empower your operations and your people—and watch your profits grow.

![Top Features of Vision-Based Workplace Safety Tools [2025]](https://static.wixstatic.com/media/379e66_7e75a4bcefe14e4fbc100abdff83bed3~mv2.jpg/v1/fit/w_1000,h_884,al_c,q_80/file.png?#)

![[The AI Show Episode 152]: ChatGPT Connectors, AI-Human Relationships, New AI Job Data, OpenAI Court-Ordered to Keep ChatGPT Logs & WPP’s Large Marketing Model](https://www.marketingaiinstitute.com/hubfs/ep%20152%20cover.png)

![[DEALS] Microsoft Visual Studio Professional 2022 + The Premium Learn to Code Certification Bundle (97% off) & Other Deals Up To 98% Off](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

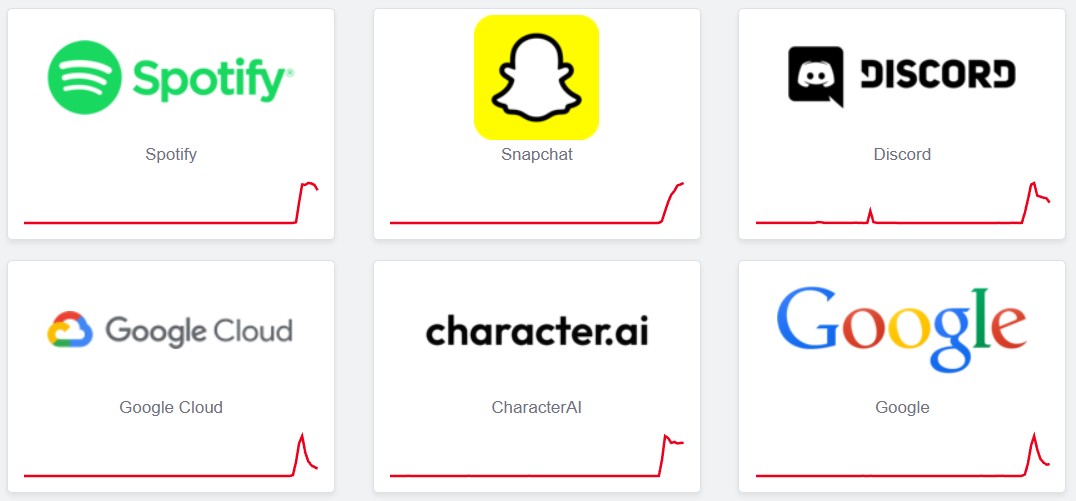

![PSA: Widespread internet outage affects Spotify, Google, Discord, Cloudflare, more [U: Fixed]](https://i0.wp.com/9to5mac.com/wp-content/uploads/sites/6/2024/07/iCloud-Private-Relay-outage-resolved.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Apple Shares Teaser Trailer for 'The Lost Bus' Starring Matthew McConaughey [Video]](https://www.iclarified.com/images/news/97582/97582/97582-640.jpg)