Compound Press Bends, Punches and Cuts Using 3D Printed Plastic

It’s not quite “bend, fold or mutilate” but this project comes close– it actually manufactures a spring clip for [Super Valid Designs] PETAL light system. In the video (embedded below) …read more

It’s not quite “bend, fold or mutilate” but this project comes close– it actually manufactures a spring clip for [Super Valid Designs] PETAL light system. In the video (embedded below) you’ll see why this tool was needed: by-hand manufacturing worked for the prototype, but really would not scale.

The lights themselves might be worthy of a post, being a modular, open source DMX stage lighting rig. Today though we’re looking at how they are manufactured– specifically how one part is manufactured. With these PETAL lights, the lights slot into a base station, which obviously requires a connection of some sort. [Super Valid Designs] opted for a spring connector, which is super valid.

It’s also a pain to work by hand: spring steel needed to be cut to length, hole punched, and bent into the specific shape required. The hand-made springs always needed adjustment after assembly, too, which is no good when people are giving you money for objects. Even when using a tent-pole spring that comes halfway to meeting their requirements, [Super Valid Designs] was not happy with the workflow.

Enter the press: 3D Printed dies rest inside a spring-loaded housing, performing the required bends. Indeed, they were able to improve the shape of the design thanks to the precision afforded by the die. The cutting step happens concurrently, with the head of a pair of tin snips mounted to the jig, and a punch finishes it off. All of this is actuated with a cheap, bog simple , hand-operated arbor press. What had been tedious minutes of work is reduced to but a moment of lever-pushing.

It great story about scaling and manufacturing that may hopefully inspire others in their projects. Perhaps with further optimization and automation, [Super Valid Designs] may find himself in the market for a modular conveyor belt design.

While this process remains fundamentally manual, we have seen automation in maker-type businesses before, like this coaster-slinging CNC setup. Of course automation doesn’t have to be part of a business model; sometimes it’s nice just to skip a tedious bunch of steps, like when building a star lamp.

![Top Features of Vision-Based Workplace Safety Tools [2025]](https://static.wixstatic.com/media/379e66_7e75a4bcefe14e4fbc100abdff83bed3~mv2.jpg/v1/fit/w_1000,h_884,al_c,q_80/file.png?#)

![[The AI Show Episode 152]: ChatGPT Connectors, AI-Human Relationships, New AI Job Data, OpenAI Court-Ordered to Keep ChatGPT Logs & WPP’s Large Marketing Model](https://www.marketingaiinstitute.com/hubfs/ep%20152%20cover.png)

![[DEALS] Microsoft Visual Studio Professional 2022 + The Premium Learn to Code Certification Bundle (97% off) & Other Deals Up To 98% Off](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

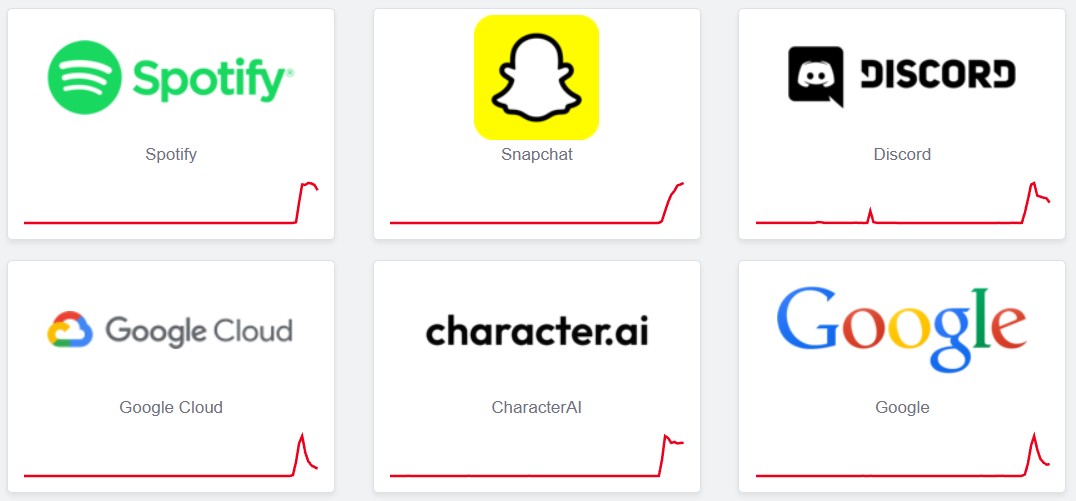

![PSA: Widespread internet outage affects Spotify, Google, Discord, Cloudflare, more [U: Fixed]](https://i0.wp.com/9to5mac.com/wp-content/uploads/sites/6/2024/07/iCloud-Private-Relay-outage-resolved.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Apple Shares Teaser Trailer for 'The Lost Bus' Starring Matthew McConaughey [Video]](https://www.iclarified.com/images/news/97582/97582/97582-640.jpg)