How to Manage Prototyping Custom Cube Boxes

Find out how to prototype custom cube boxes for improving your packaging design and design a product that will cut the throat of competition in the market.

To make a perfect custom cube box, skill, time, precision, and the ability to understand your brand are paramount. Prototyping is a critical part of this process since it involves creating many models of designs that may be subjected to early testing to ascertain their fitness for real production before being embarked on.

Whether one is creating mini cube boxes in the case of small products or large cube boxes, which are specially designed due to complex packaging needs work, the importance that the prototyping phase offers cannot be overemphasized. In this guide, we will discuss how best to approach managing prototyping for custom cube boxes to achieve an ideal design suited for your business needs.

Significance of Prototyping

Prototyping is particularly important in the case of custom small cube boxes to guarantee that, apart from looking good, the product is practical. A good tangible model developed is essential in gauging the endurance, sturdiness and functionality of the packaging. In this stage, one is also able to consider the structural integrity of the box with a view on whether it is fit for transportation and storage. The choice of cardboard cube boxes as the ones to be used during proto-typing means that the final product will not be too expensive to be bought in bulk.

Selecting the Type of Material for Your Prototypes

Choosing the material is critical when it comes to dealing with the prototyping of the custom cube boxes. For many brands, cardboard is popular, particularly for standard small cube cardboard boxes. Businesses find cardboard versatile, easy to process for branding and recycling-friendly. Furthermore, it is important to the weight and size of the product the box has to contain and carry. For heavier products or products that need extra protection, you may want to use a more durable material for the prototypes to know that the box you’ll design in the end can offer as much support and as much protection as needed.

Designing Prototype

After the choice of the material, the subsequent action is the design of individual cube boxes as per your requirements. It is about making choices about size, shape and additional details like flaps, folds and fasteners. This is also the right time to try out placing the logo or other branding images and colours on the custom cube boxes that you want. The need will be to know that the design not only looks good but is functional as well. With the new developments in the custom cube boxes printed options, you can do a lot when it comes to branding your boxes.

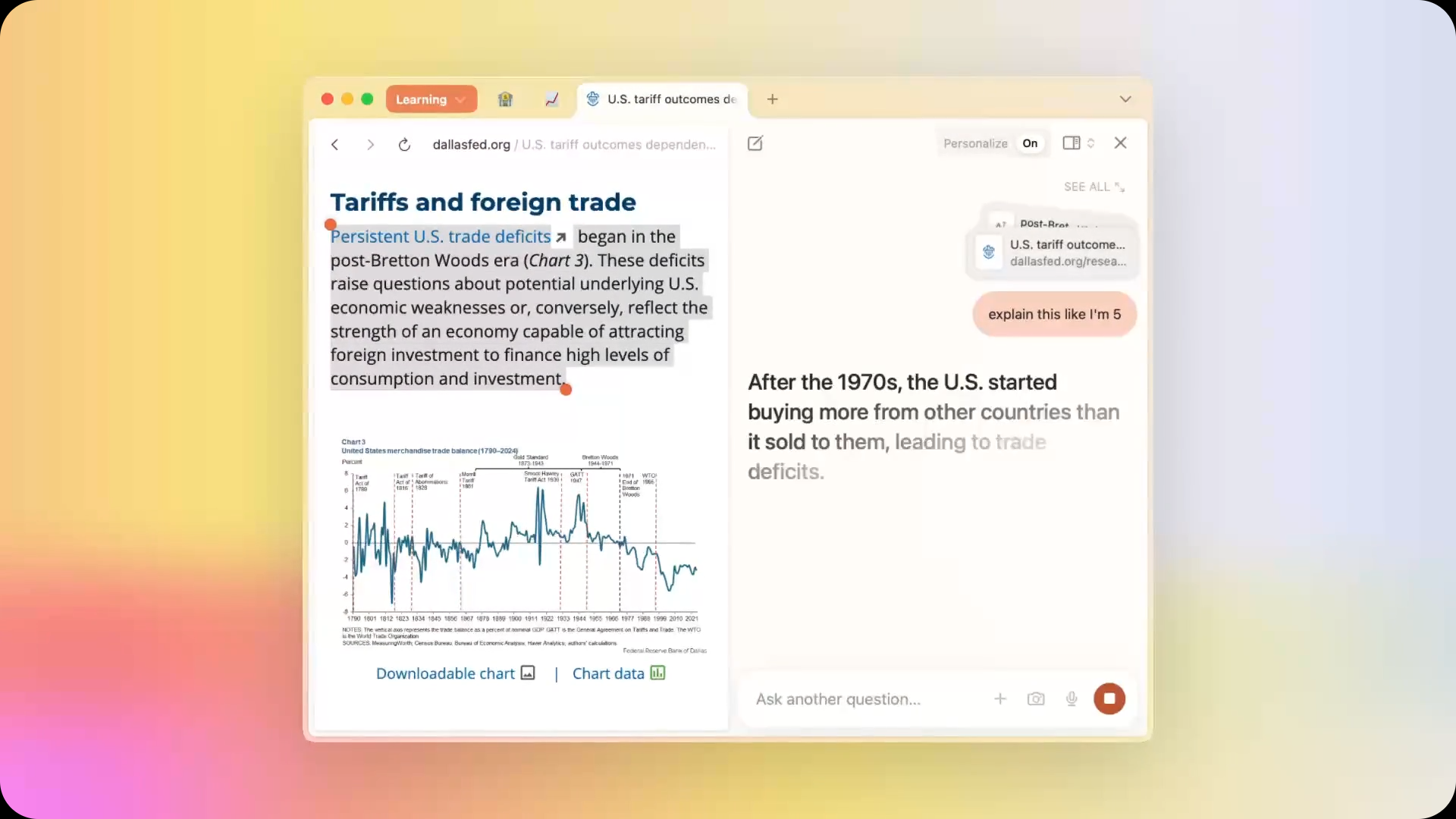

Protocol in Applying Technology

Traditionally, the process of prototyping was a very long and resource-consuming process. Many companies use technologies like CAD tools to reduce the time needed. CAD software helps you design your custom cube boxes in detail, with very fine detailing that will only require a few adjustments as one deems fit. These designs can then be immediately downloaded to a Digital Printer or a Cutting Machine to produce a prototype. This gets rid of any chance of a design going off in a completely unanticipated direction and instead guarantees that the last result is precisely what you expect and want.

Testing and Refining Your Prototype

Once our prototype is ready for construction, the last step is to conduct a series of tests. This is critical in as much as it helps to determine whether the custom cube boxes will live up to their expectations in real conditions. Check how strong the box is, how easy is it to assemble and how well it will shield your product. If your product is a mini cube box for small items, test it as the goal is to achieve adequate protection for the items, while still keeping the box small. After testing, get information and adapt your target design based on the findings. Modifications can be changes in thickness, quality of the print or strengthening of the structural flaws.

How to Manage the Cost of Prototyping Correctly

One of the challenges that crop up when making cube boxes is how to control the cost of prototyping. It is also interesting to incorporate high-quality materials and superior functions, but excessive-quality improvement will cause high costs. If you have less budget, first build small cube box prototypes from cheap and easily available material. Furthermore, we can order prototypes in large quantities for customers to get lower prices per each. Cooperating with the suppliers who deliver cube boxes wholesale can also be advantageous when dealing with cost issues but not quality ones.

Finalizing Your Prototype and Moving to Production

When you have fine-tuned the prototype to the desired level, it is now appropriate for the firm to seal the design and begin moving toward production. At this point, you can order cube boxes in bulk that will correspond to your fine-tuned version of a prototype. Make sure that every design is created in its specifications so that you can get the final boxes from a supplier at a large scale.

When from the USA, it is good to take into consideration production schedules and transport schedules. Even when dealing with keepsake custom cube boxes in the USA or even more ordinary appearance, the shift from prototype to mass production should not be very much of a problem especially if sufficient pre-planning has been made.

Conclusion

Organizing the creation of prototyping for the custom cube boxes is a critical factor in providing effective packaging with functional and beautiful design for cube boxes according to the overall image of the brand. Taking time to find the right material, tweaking your design and even creating prototypes you will be well prepared to have packaging that will capture attention in the market. No matter if you are coming up with new custom cube boxes with logos or you only require useful solutions to your packaging needs, taking your time and effort into prototyping is ultimately beneficial because it will give you and your customers value for your money.

![Top Features of Vision-Based Workplace Safety Tools [2025]](https://static.wixstatic.com/media/379e66_7e75a4bcefe14e4fbc100abdff83bed3~mv2.jpg/v1/fit/w_1000,h_884,al_c,q_80/file.png?#)

![[The AI Show Episode 152]: ChatGPT Connectors, AI-Human Relationships, New AI Job Data, OpenAI Court-Ordered to Keep ChatGPT Logs & WPP’s Large Marketing Model](https://www.marketingaiinstitute.com/hubfs/ep%20152%20cover.png)

![[DEALS] Microsoft Visual Studio Professional 2022 + The Premium Learn to Code Certification Bundle (97% off) & Other Deals Up To 98% Off](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

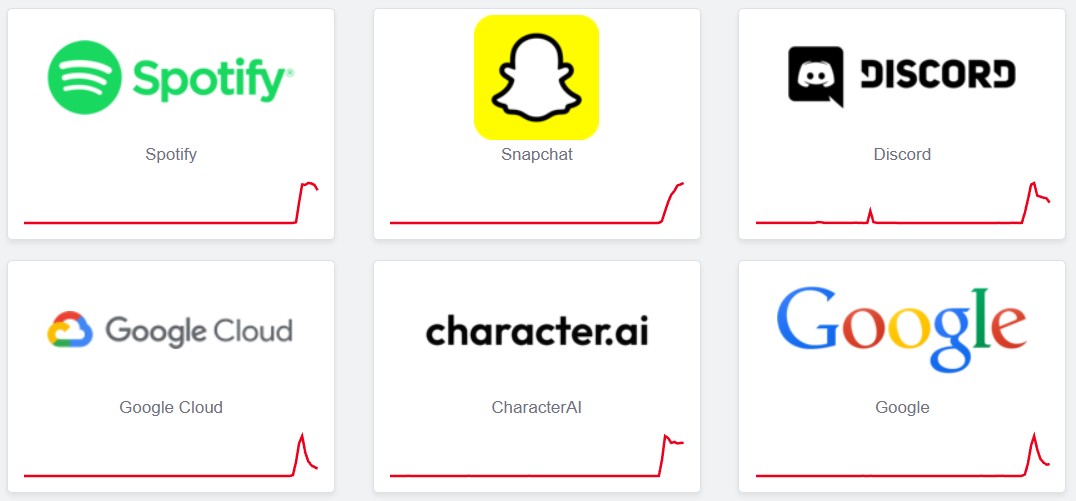

![PSA: Widespread internet outage affects Spotify, Google, Discord, Cloudflare, more [U: Fixed]](https://i0.wp.com/9to5mac.com/wp-content/uploads/sites/6/2024/07/iCloud-Private-Relay-outage-resolved.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Apple Shares Teaser Trailer for 'The Lost Bus' Starring Matthew McConaughey [Video]](https://www.iclarified.com/images/news/97582/97582/97582-640.jpg)