A Toolchanging Delta 3D printer

We’ve seen quite a few delta 3D printers, and a good number of toolchanging printers, but not many that combine both worlds. Fortunately, [Ben Wolpert]’s project fills that gap with …read more

We’ve seen quite a few delta 3D printers, and a good number of toolchanging printers, but not many that combine both worlds. Fortunately, [Ben Wolpert]’s project fills that gap with a particularly elegant and precise delta toolchanger.

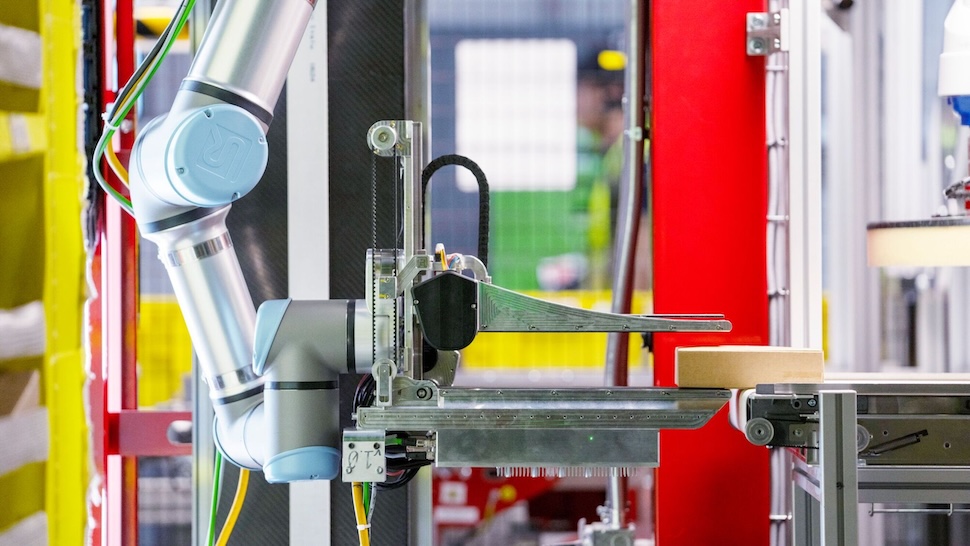

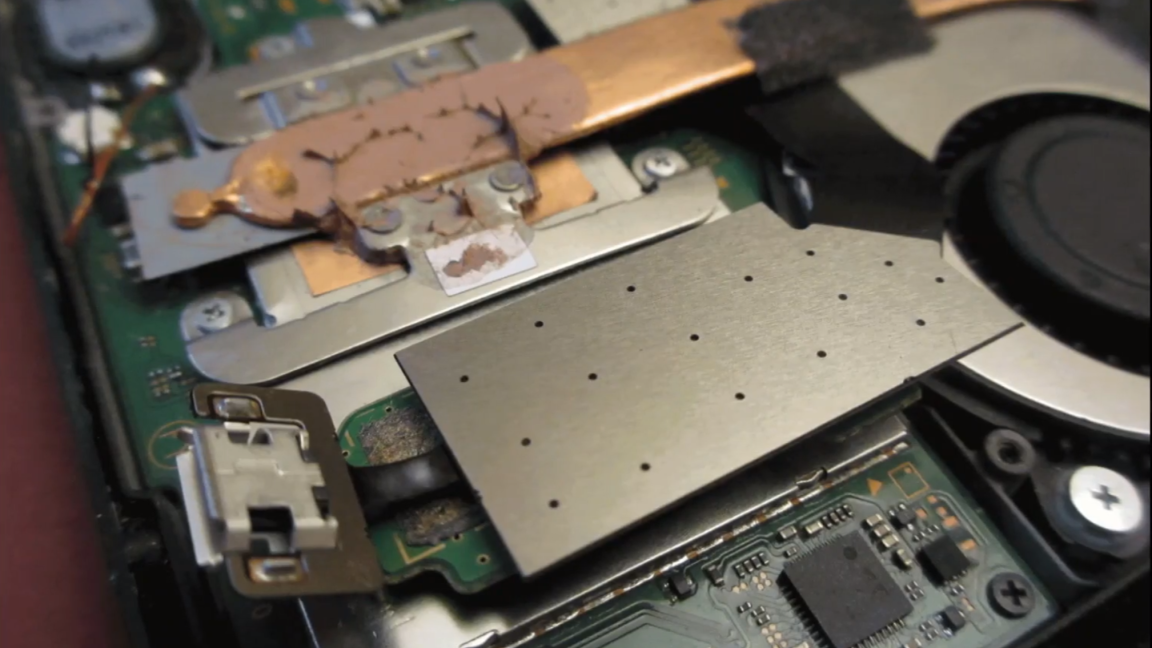

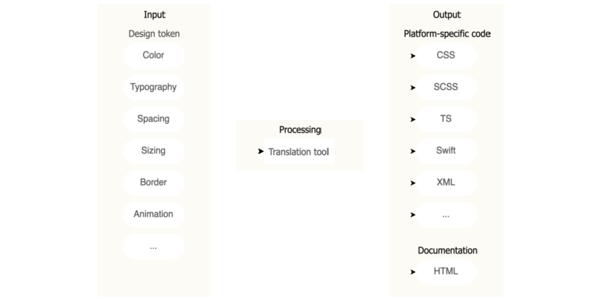

The hotend uses three steel spheres and triangular brackets to make a repeatable three-point contact with the toolhead frame, and three pairs of corresponding magnets hold it in place. The magnets aren’t in contact, and the three magnets on the toolhead are mounted in a rotating ring. A motorized pulley on the printer’s frame drives a cable which runs through a flexible guide and around the rotating ring.

The whole setup is very reminiscent of the Jubilee toolchanging system, except that in this case, the pulley rotates the ring of magnets rather than a mechanical lock. By rotating the ring of magnets about 60 degrees, the system can move the pairs of magnets far enough apart to remove the hotend without much force.

The whole setup is very reminiscent of the Jubilee toolchanging system, except that in this case, the pulley rotates the ring of magnets rather than a mechanical lock. By rotating the ring of magnets about 60 degrees, the system can move the pairs of magnets far enough apart to remove the hotend without much force.

The rest of the toolchanging system is fairly straightforward: each tool’s parking area consists of two metal posts which slot through corresponding holes in the hotend’s frame, and the motherboard uses some RepRapFirmware macros to coordinate the tool changes. The only downside is that a cooling fan for the hotend still hadn’t been implemented, but a desk fan seemed to work well enough in [Ben]’s tests. The files for the necessary hardware and software customizations are all available on GitHub.

We’ve only seen a similar toolchanging system for a delta printer once before, but we have seen a great variety of toolchangers on the more common Cartesian systems. Don’t like the idea of changing extruders? We’ve also seen a multi-extruder printer that completely eliminates tool switching.

![[The AI Show Episode 147]: OpenAI Abandons For-Profit Plan, AI College Cheating Epidemic, Apple Says AI Will Replace Search Engines & HubSpot’s AI-First Scorecard](https://www.marketingaiinstitute.com/hubfs/ep%20147%20cover.png)

.jpeg?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

_ElenaBs_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

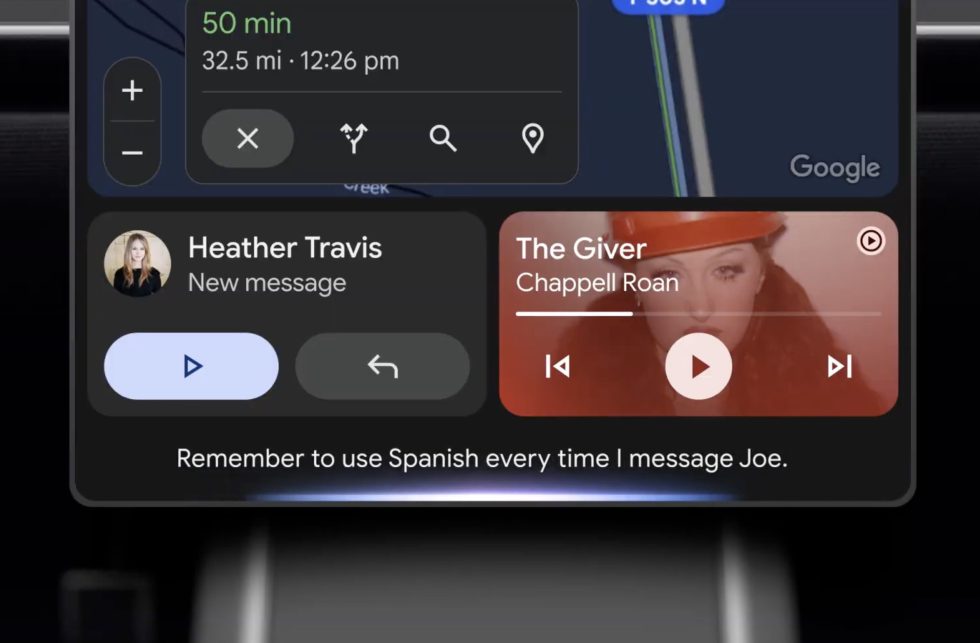

![Gemini coming to Android Auto with Live, automatic translation, more [Video]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/05/google-gemini-android-auto-1.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Apple Working on Brain-Controlled iPhone With Synchron [Report]](https://www.iclarified.com/images/news/97312/97312/97312-640.jpg)