What I Learned from Lean Manufacturing Training!

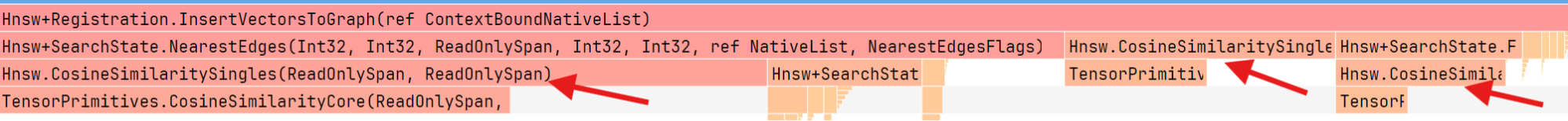

During my industrial training, I had the opportunity to explore Lean Manufacturing, a system designed to make production more efficient by eliminating waste and focusing on value creation. I learned about important tools like 5S, which stands for Sort, Set in order, Shine, Standardize, and Sustain. This method helps keep workspaces clean and organized, which is essential for safety and productivity. Another key concept I studied was Kaizen, which means continuous improvement. It emphasizes that small daily changes can lead to significant improvements over time. I also gained practical experience with Just-in-Time inventory management, which ensures materials arrive exactly when needed, reducing storage costs and avoiding overproduction. This training helped me connect the theoretical concepts learned in class with real-world production challenges. I realized that efficiency is not only about speed but also about smart use of resources and people. I saw how teamwork and communication play a vital role on the factory floor. Lean Manufacturing is not just a set of techniques; it is a culture of continuous problem solving and improvement. As an Industrial and Production Engineering graduate, I believe this mindset will guide me in all my future professional endeavors.

During my industrial training, I had the opportunity to explore Lean Manufacturing, a system designed to make production more efficient by eliminating waste and focusing on value creation. I learned about important tools like 5S, which stands for Sort, Set in order, Shine, Standardize, and Sustain. This method helps keep workspaces clean and organized, which is essential for safety and productivity.

Another key concept I studied was Kaizen, which means continuous improvement. It emphasizes that small daily changes can lead to significant improvements over time. I also gained practical experience with Just-in-Time inventory management, which ensures materials arrive exactly when needed, reducing storage costs and avoiding overproduction.

This training helped me connect the theoretical concepts learned in class with real-world production challenges. I realized that efficiency is not only about speed but also about smart use of resources and people. I saw how teamwork and communication play a vital role on the factory floor. Lean Manufacturing is not just a set of techniques; it is a culture of continuous problem solving and improvement. As an Industrial and Production Engineering graduate, I believe this mindset will guide me in all my future professional endeavors.

![Epic Games: Fortnite is offline for Apple devices worldwide after app store rejection [updated]](https://helios-i.mashable.com/imagery/articles/00T6DmFkLaAeJiMZlCJ7eUs/hero-image.fill.size_1200x675.v1747407583.jpg)

![[The AI Show Episode 146]: Rise of “AI-First” Companies, AI Job Disruption, GPT-4o Update Gets Rolled Back, How Big Consulting Firms Use AI, and Meta AI App](https://www.marketingaiinstitute.com/hubfs/ep%20146%20cover.png)

![How to make Developer Friends When You Don't Live in Silicon Valley, with Iraqi Engineer Code;Life [Podcast #172]](https://cdn.hashnode.com/res/hashnode/image/upload/v1747360508340/f07040cd-3eeb-443c-b4fb-370f6a4a14da.png?#)

.png?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

![[Virtual Event] Strategic Security for the Modern Enterprise](https://eu-images.contentstack.com/v3/assets/blt6d90778a997de1cd/blt55e4e7e277520090/653a745a0e92cc040a3e9d7e/Dark_Reading_Logo_VirtualEvent_4C.png?width=1280&auto=webp&quality=80&disable=upscale#)

-xl-(1)-xl-xl.jpg)

![How to upgrade the M4 Mac mini SSD and save hundreds [Video]](https://i0.wp.com/9to5mac.com/wp-content/uploads/sites/6/2025/05/M4-Mac-mini-SSD-Upgrade-Tutorial-2TB.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![‘Apple in China’ book argues that the iPhone could be killed overnight [Updated]](https://i0.wp.com/9to5mac.com/wp-content/uploads/sites/6/2025/05/Apple-in-China-review.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![iPhone 17 Air Could Get a Boost From TDK's New Silicon Battery Tech [Report]](https://www.iclarified.com/images/news/97344/97344/97344-640.jpg)

![Vision Pro Owners Say They Regret $3,500 Purchase [WSJ]](https://www.iclarified.com/images/news/97347/97347/97347-640.jpg)

![Apple Showcases 'Magnifier on Mac' and 'Music Haptics' Accessibility Features [Video]](https://www.iclarified.com/images/news/97343/97343/97343-640.jpg)

![Sony WH-1000XM6 Unveiled With Smarter Noise Canceling and Studio-Tuned Sound [Video]](https://www.iclarified.com/images/news/97341/97341/97341-640.jpg)

![Apple Stops Signing iPadOS 17.7.7 After Reports of App Login Issues [Updated]](https://images.macrumors.com/t/DoYicdwGvOHw-VKkuNvoxYs3pfo=/1920x/article-new/2023/06/ipados-17.jpg)

![[WIP][Godot 4 & Py] BrainsIAAndPixels – 3D PixelArt Game with AI-Controlled NPCs](https://media2.dev.to/dynamic/image/width%3D1000,height%3D500,fit%3Dcover,gravity%3Dauto,format%3Dauto/https:%2F%2Fdev-to-uploads.s3.amazonaws.com%2Fuploads%2Farticles%2F5iysvd2f7togsdd7b97p.png)