Forget deep sea mining. This startup is getting critical minerals from seaweed instead

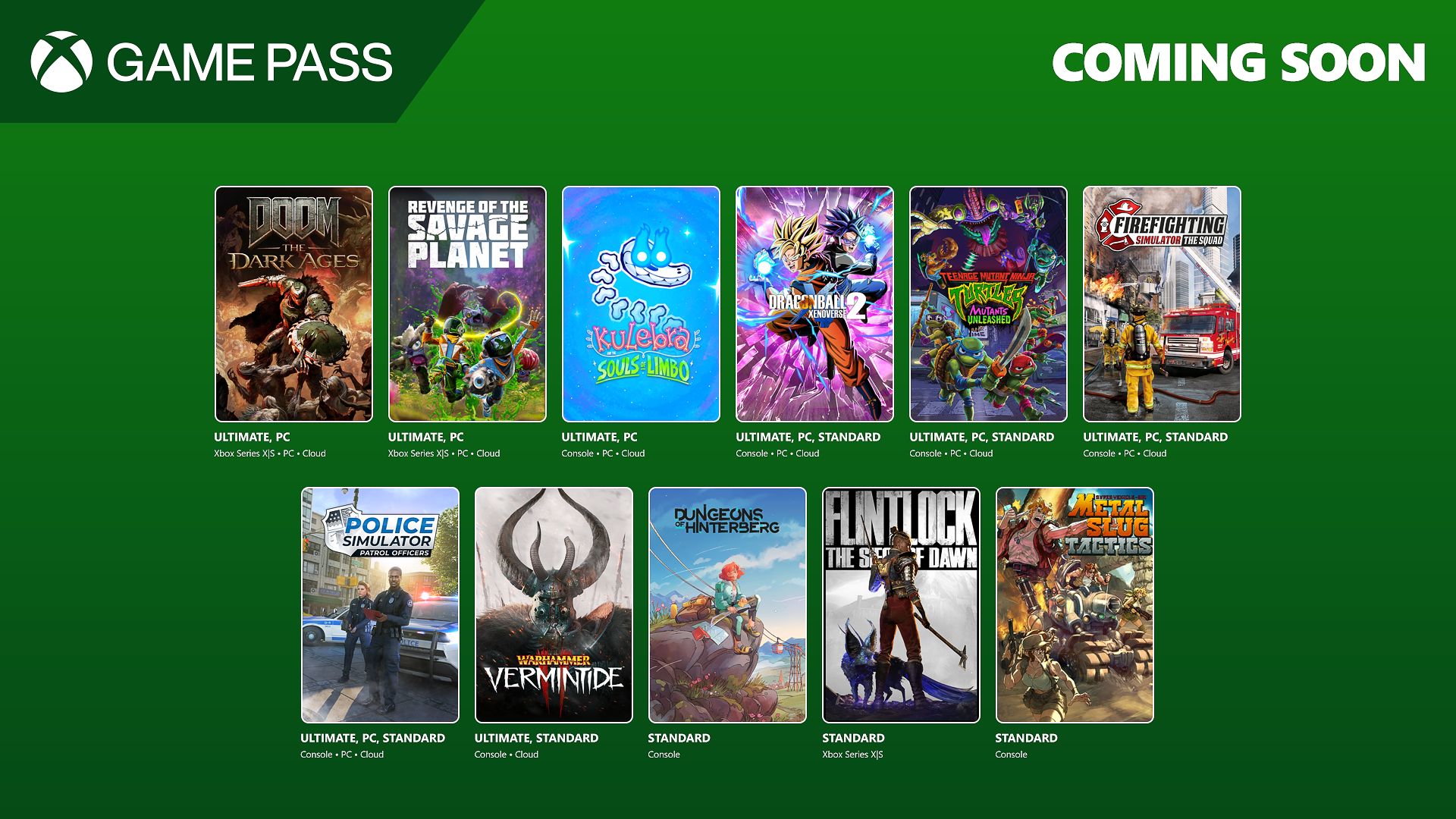

On farms off the coast of Alaska and in Mexico, a company called Blue Evolution grows seaweed used in food and skincare products. But five years ago, while studying the potential for seaweed to be used in bioenergy, the company discovered something else: The algae also contains critical minerals. The research, conducted with Pacific Northwest National Labs, identified the presence of scandium, an expensive rare earth element that’s produced in tiny volumes globally. The seaweed also contains other rare earth elements and platinum group metals that can be used to make products ranging from EV batteries to motors for wind turbines. “That generated a lot of excitement,” says Beau Perry, CEO of Blue Evolution. “Everyone was like, ‘Can you mine with seaweed?’” The company undertook more research into the area, and today it launched a new initiative, Orca Minerals, that’s focused on the new form of mining. Instead of blasting rocks or the seabed, the process makes use of the fact that seaweed naturally absorbs minerals from seawater as it grows. [Photo: Rachelle Hacmac/Blue Evolution] At its lab in San Jose, the company is analyzing samples of seaweed that it grows in seawater tanks on the Mexican coast and in the ocean in Alaska. With the right location, and the right strain of seaweed, Perry says, it’s possible to harvest meaningful amounts of certain minerals. The team identifies and selectively breeds seaweed strains, and is currently analyzing one of those proprietary strains. “We’re starting to select the characteristics that should yield more, with faster growth, but also more solid content and more mineral content,” Perry says. The content of critical minerals like cobalt or palladium is small, but that’s also true in traditional mining. “When you’re mining rare earths, it’s just mostly wasted material. You need a huge amount of rock,” he says. “Rare earth elements are not that much more concentrated in those deposits than in some of the seaweed samples we’ve seen.” Some other startups are working on processes to extract minerals from land using plants, like a company called Metalplant that’s mining nickel with crops grown in Albania. Seaweed has some advantages: It grows much more quickly and can concentrate minerals at a higher proportion, so the yield can be greater. And while there’s a fixed stock of minerals in soil, currents in the ocean continually replenish supply. [Photo: Rachelle Hacmac/Blue Evolution] The rest of the seaweed also has value—as nutrients, pigments, or carbon that can be used to make seaweed-based textiles, plastic, and other materials; critical minerals are a side benefit. As the biomaterials market grows, that would simultaneously mean more potential to displace traditional mining on land. If the company grows seven-figure tons of dry seaweed in Alaska to meet demand for biomaterials, for example, Perry says it could also produce enough scandium to be a major player in the global market. (For some other minerals and elements that are produced at bigger scales, it would contribute a much smaller percentage.) Mining from seaweed, rather than rocks, could help avoid some of the environmental impact of getting components that are necessary in things like electronics and EV batteries. Traditional mining destroys wildlife habitats; pollutes water, soil, and the air; uses large amounts of energy; and creates piles of waste. The Trump administration also wants to fast-track deep-sea mining—extracting minerals from the ocean floor—something scientists say could cause irreparable harm to marine ecosystems. Growing and harvesting seaweed doesn’t cause those problems. Refining minerals from seaweed also takes less energy and is a cleaner process than traditional refining, Perry says. The company is working on its own green-chemistry-based extraction techniques that could potentially bypass the need to use a secondary refinery. The work is still in progress, and the company wants to ensure it can predictably harvest a certain volume of critical minerals from its seaweed. But it expects to have an operational prototype by 2027. Commercial production could begin in 2028.

On farms off the coast of Alaska and in Mexico, a company called Blue Evolution grows seaweed used in food and skincare products. But five years ago, while studying the potential for seaweed to be used in bioenergy, the company discovered something else: The algae also contains critical minerals.

The research, conducted with Pacific Northwest National Labs, identified the presence of scandium, an expensive rare earth element that’s produced in tiny volumes globally. The seaweed also contains other rare earth elements and platinum group metals that can be used to make products ranging from EV batteries to motors for wind turbines. “That generated a lot of excitement,” says Beau Perry, CEO of Blue Evolution. “Everyone was like, ‘Can you mine with seaweed?’”

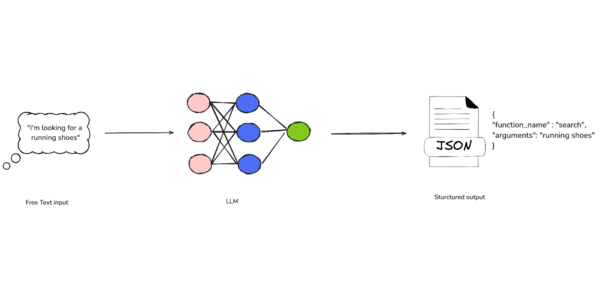

The company undertook more research into the area, and today it launched a new initiative, Orca Minerals, that’s focused on the new form of mining. Instead of blasting rocks or the seabed, the process makes use of the fact that seaweed naturally absorbs minerals from seawater as it grows.

At its lab in San Jose, the company is analyzing samples of seaweed that it grows in seawater tanks on the Mexican coast and in the ocean in Alaska. With the right location, and the right strain of seaweed, Perry says, it’s possible to harvest meaningful amounts of certain minerals. The team identifies and selectively breeds seaweed strains, and is currently analyzing one of those proprietary strains. “We’re starting to select the characteristics that should yield more, with faster growth, but also more solid content and more mineral content,” Perry says.

The content of critical minerals like cobalt or palladium is small, but that’s also true in traditional mining. “When you’re mining rare earths, it’s just mostly wasted material. You need a huge amount of rock,” he says. “Rare earth elements are not that much more concentrated in those deposits than in some of the seaweed samples we’ve seen.”

Some other startups are working on processes to extract minerals from land using plants, like a company called Metalplant that’s mining nickel with crops grown in Albania. Seaweed has some advantages: It grows much more quickly and can concentrate minerals at a higher proportion, so the yield can be greater. And while there’s a fixed stock of minerals in soil, currents in the ocean continually replenish supply.

The rest of the seaweed also has value—as nutrients, pigments, or carbon that can be used to make seaweed-based textiles, plastic, and other materials; critical minerals are a side benefit. As the biomaterials market grows, that would simultaneously mean more potential to displace traditional mining on land. If the company grows seven-figure tons of dry seaweed in Alaska to meet demand for biomaterials, for example, Perry says it could also produce enough scandium to be a major player in the global market. (For some other minerals and elements that are produced at bigger scales, it would contribute a much smaller percentage.)

Mining from seaweed, rather than rocks, could help avoid some of the environmental impact of getting components that are necessary in things like electronics and EV batteries. Traditional mining destroys wildlife habitats; pollutes water, soil, and the air; uses large amounts of energy; and creates piles of waste. The Trump administration also wants to fast-track deep-sea mining—extracting minerals from the ocean floor—something scientists say could cause irreparable harm to marine ecosystems.

Growing and harvesting seaweed doesn’t cause those problems. Refining minerals from seaweed also takes less energy and is a cleaner process than traditional refining, Perry says. The company is working on its own green-chemistry-based extraction techniques that could potentially bypass the need to use a secondary refinery.

The work is still in progress, and the company wants to ensure it can predictably harvest a certain volume of critical minerals from its seaweed. But it expects to have an operational prototype by 2027. Commercial production could begin in 2028.

![[The AI Show Episode 146]: Rise of “AI-First” Companies, AI Job Disruption, GPT-4o Update Gets Rolled Back, How Big Consulting Firms Use AI, and Meta AI App](https://www.marketingaiinstitute.com/hubfs/ep%20146%20cover.png)

.jpg?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

_Brian_Jackson_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

_Steven_Jones_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

Stolen 884,000 Credit Card Details on 13 Million Clicks from Users Worldwide.webp?#)

![Google rolling out Nest Wifi Pro April 2025 update [U]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2022/10/Nest-Wifi-Pro-1.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Apple Seeds visionOS 2.5 RC to Developers [Download]](https://www.iclarified.com/images/news/97240/97240/97240-640.jpg)

![Apple Seeds tvOS 18.5 RC to Developers [Download]](https://www.iclarified.com/images/news/97243/97243/97243-640.jpg)

![Apple Releases macOS Sequoia 15.5 RC to Developers [Download]](https://www.iclarified.com/images/news/97245/97245/97245-640.jpg)