Power of Manufacturing Data Analytics: A Strategic Advantage

Introduction In today's competitive manufacturing landscape, leveraging data analytics is no longer optional—it's imperative. Manufacturers are increasingly turning to data-driven insights to optimize operations, reduce costs, and enhance product quality. This post delves into the strategic advantages of manufacturing data analytics, highlighting its transformative impact on the industry. Key Benefits of Manufacturing Data Analytics Enhanced Operational Efficiency By analyzing production data in real-time, manufacturers can identify bottlenecks, streamline workflows, and reduce downtime. Predictive analytics further aids in anticipating maintenance needs, minimizing unplanned outages. Improved Product Quality Data analytics enables the monitoring of quality metrics throughout the production process. This proactive approach helps in identifying defects early, ensuring consistent product quality and customer satisfaction. Cost Reduction Through the analysis of resource utilization and waste patterns, manufacturers can implement cost-saving measures. Optimizing inventory levels and energy consumption leads to significant cost reductions. Supply Chain Optimization Data analytics provides insights into supply chain dynamics, facilitating better demand forecasting and inventory management. This results in a more responsive and efficient supply chain. Implementing Data Analytics in Manufacturing: A Step-by-Step Guide Data Collection Integrate IoT sensors and ERP systems to gather real-time data from various production stages. Data Processing Utilize data processing tools to clean and organize the collected data for analysis. Data Analysis Apply statistical and machine learning models to extract meaningful insights from the data. Visualization Develop dashboards and reports to present the analysis results to stakeholders effectively. Actionable Insights Translate data insights into actionable strategies to enhance manufacturing processes. Real-World Applications Companies like AQe Digital have successfully implemented data analytics solutions to transform manufacturing operations. By adopting smart production planning and scheduling tools, they have achieved significant improvements in efficiency and cost savings. Conclusion Embracing manufacturing data analytics is a strategic move towards achieving operational excellence and maintaining a competitive edge. By implementing data-driven strategies, manufacturers can unlock new levels of efficiency, quality, and profitability. For a deeper dive into the benefits and real-world applications of manufacturing data analytics, check out the full article on Manufacturing Data Analytics For Growth, Efficiency, and Innovation. You’ll gain valuable insights to guide your next steps in transforming your manufacturing operations.

Introduction

In today's competitive manufacturing landscape, leveraging data analytics is no longer optional—it's imperative. Manufacturers are increasingly turning to data-driven insights to optimize operations, reduce costs, and enhance product quality. This post delves into the strategic advantages of manufacturing data analytics, highlighting its transformative impact on the industry.

Key Benefits of Manufacturing Data Analytics

Enhanced Operational Efficiency

By analyzing production data in real-time, manufacturers can identify bottlenecks, streamline workflows, and reduce downtime. Predictive analytics further aids in anticipating maintenance needs, minimizing unplanned outages.

Improved Product Quality

Data analytics enables the monitoring of quality metrics throughout the production process. This proactive approach helps in identifying defects early, ensuring consistent product quality and customer satisfaction.

Cost Reduction

Through the analysis of resource utilization and waste patterns, manufacturers can implement cost-saving measures. Optimizing inventory levels and energy consumption leads to significant cost reductions.

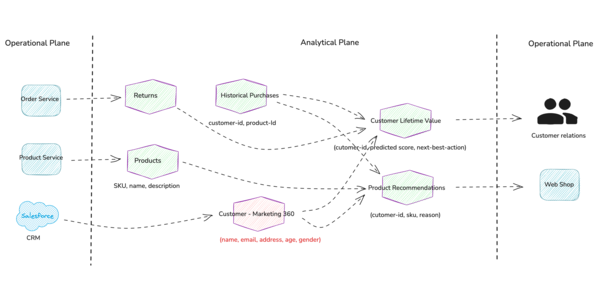

Supply Chain Optimization

Data analytics provides insights into supply chain dynamics, facilitating better demand forecasting and inventory management. This results in a more responsive and efficient supply chain.

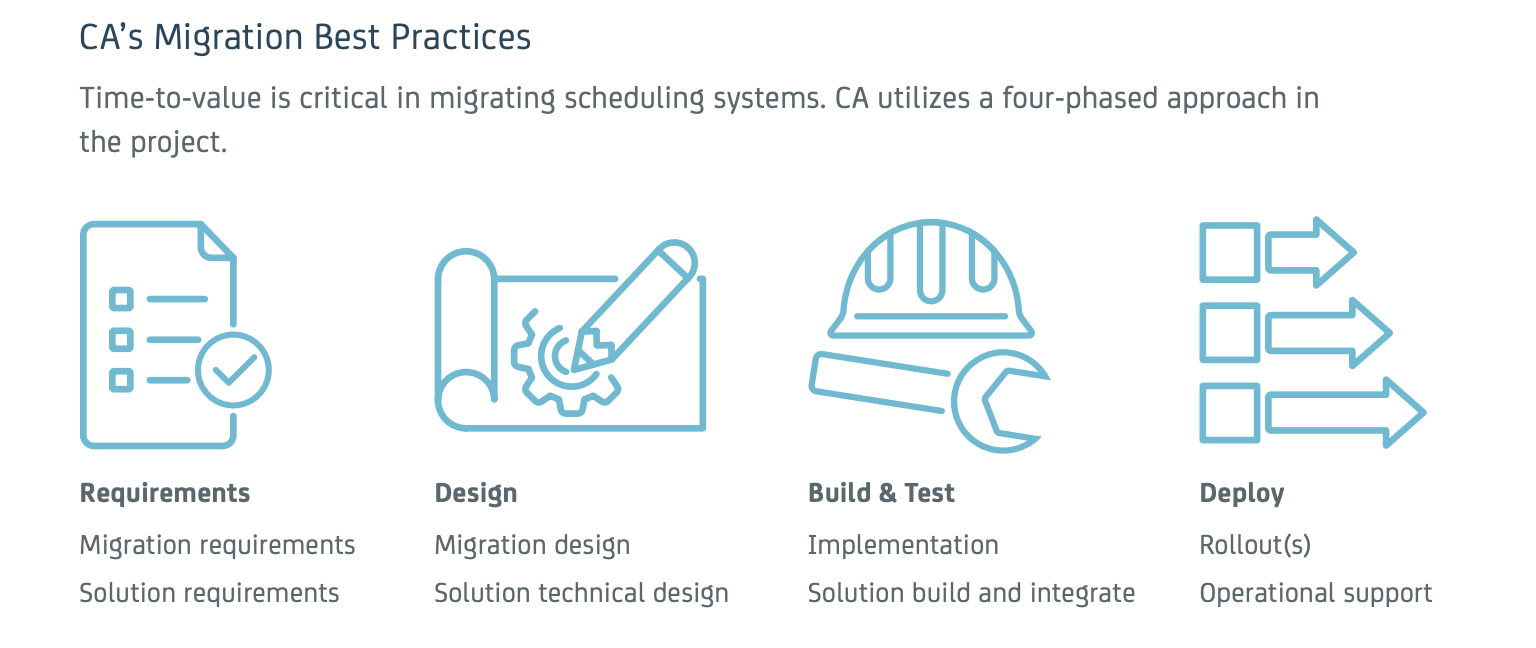

Implementing Data Analytics in Manufacturing: A Step-by-Step Guide

Data Collection

Integrate IoT sensors and ERP systems to gather real-time data from various production stages.

Data Processing

Utilize data processing tools to clean and organize the collected data for analysis.

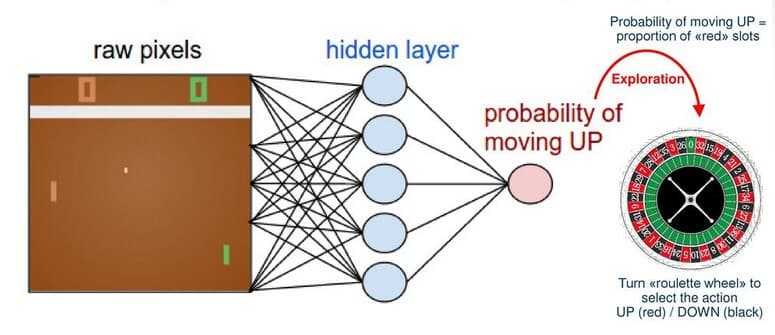

Data Analysis

Apply statistical and machine learning models to extract meaningful insights from the data.

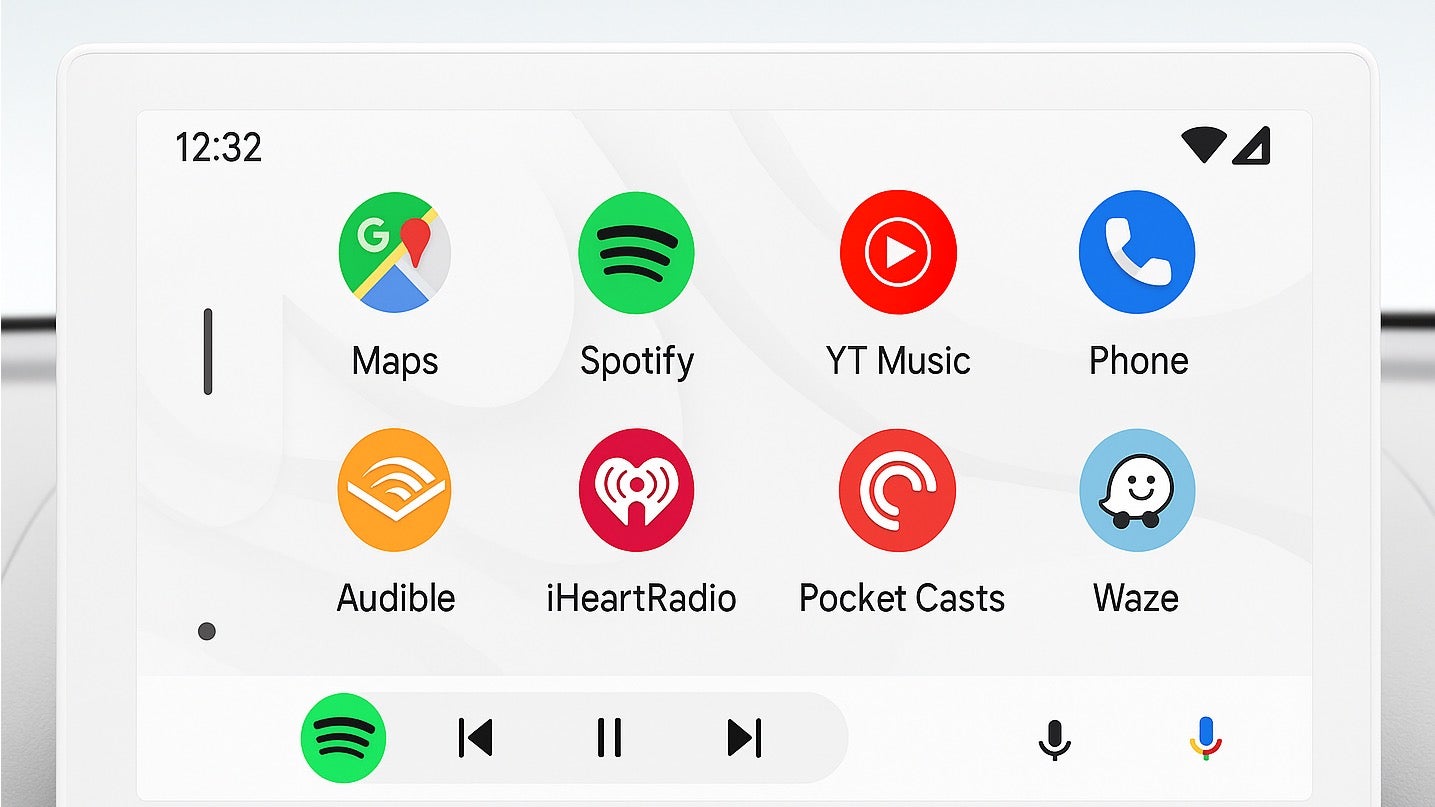

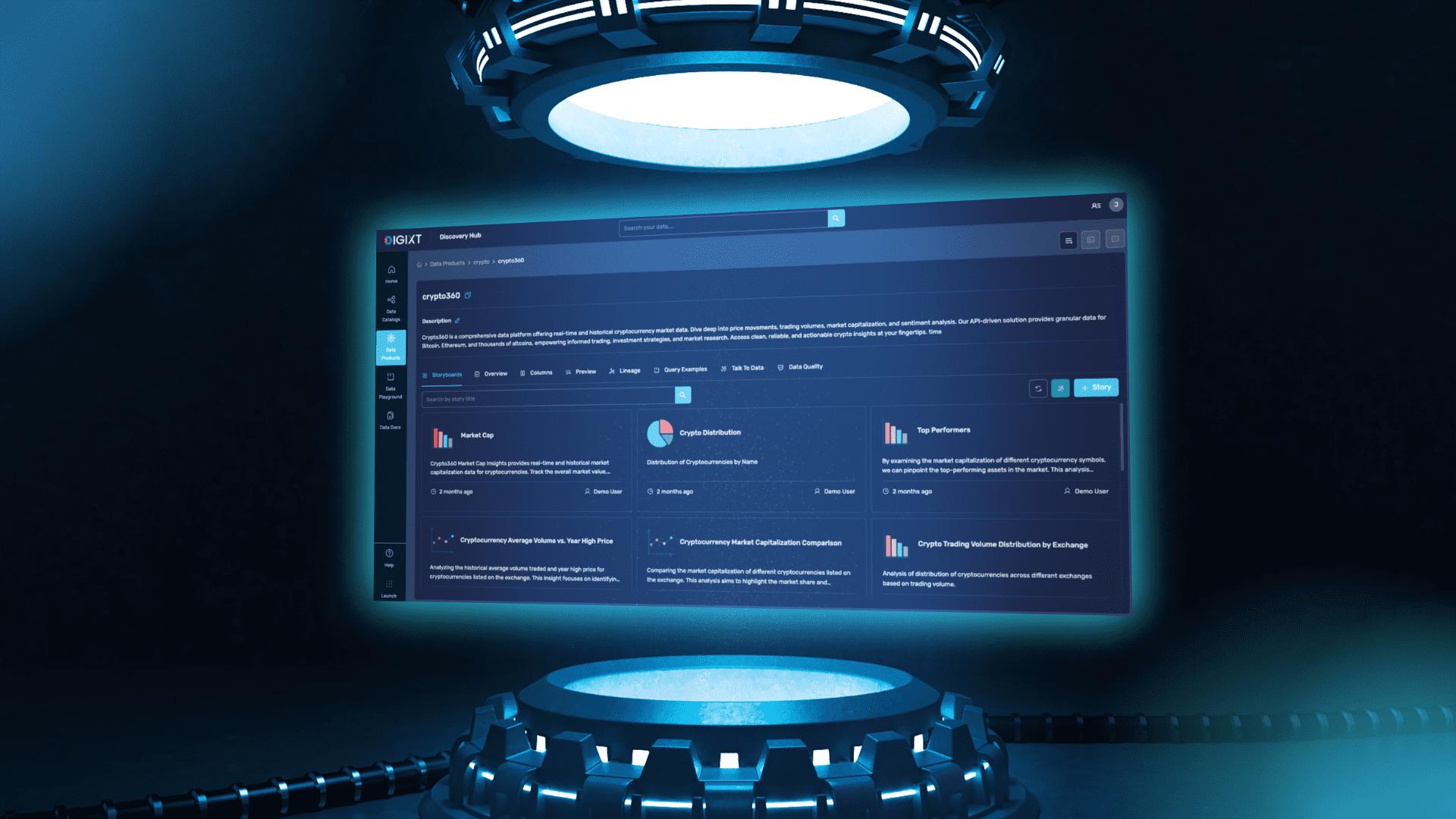

Visualization

Develop dashboards and reports to present the analysis results to stakeholders effectively.

Actionable Insights

Translate data insights into actionable strategies to enhance manufacturing processes.

Real-World Applications

Companies like AQe Digital have successfully implemented data analytics solutions to transform manufacturing operations. By adopting smart production planning and scheduling tools, they have achieved significant improvements in efficiency and cost savings.

Conclusion

Embracing manufacturing data analytics is a strategic move towards achieving operational excellence and maintaining a competitive edge. By implementing data-driven strategies, manufacturers can unlock new levels of efficiency, quality, and profitability.

For a deeper dive into the benefits and real-world applications of manufacturing data analytics, check out the full article on Manufacturing Data Analytics For Growth, Efficiency, and Innovation. You’ll gain valuable insights to guide your next steps in transforming your manufacturing operations.

_courtesy_VERTICAL.jpg)

![[The AI Show Episode 145]: OpenAI Releases o3 and o4-mini, AI Is Causing “Quiet Layoffs,” Executive Order on Youth AI Education & GPT-4o’s Controversial Update](https://www.marketingaiinstitute.com/hubfs/ep%20145%20cover.png)

![[DEALS] Mail Backup X Individual Edition: Lifetime Subscription (72% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

![Apple Reports Q2 FY25 Earnings: $95.4 Billion in Revenue, $24.8 Billion in Net Income [Chart]](https://www.iclarified.com/images/news/97188/97188/97188-640.jpg)

![Apple Ships 55 Million iPhones, Claims Second Place in Q1 2025 Smartphone Market [Report]](https://www.iclarified.com/images/news/97185/97185/97185-640.jpg)