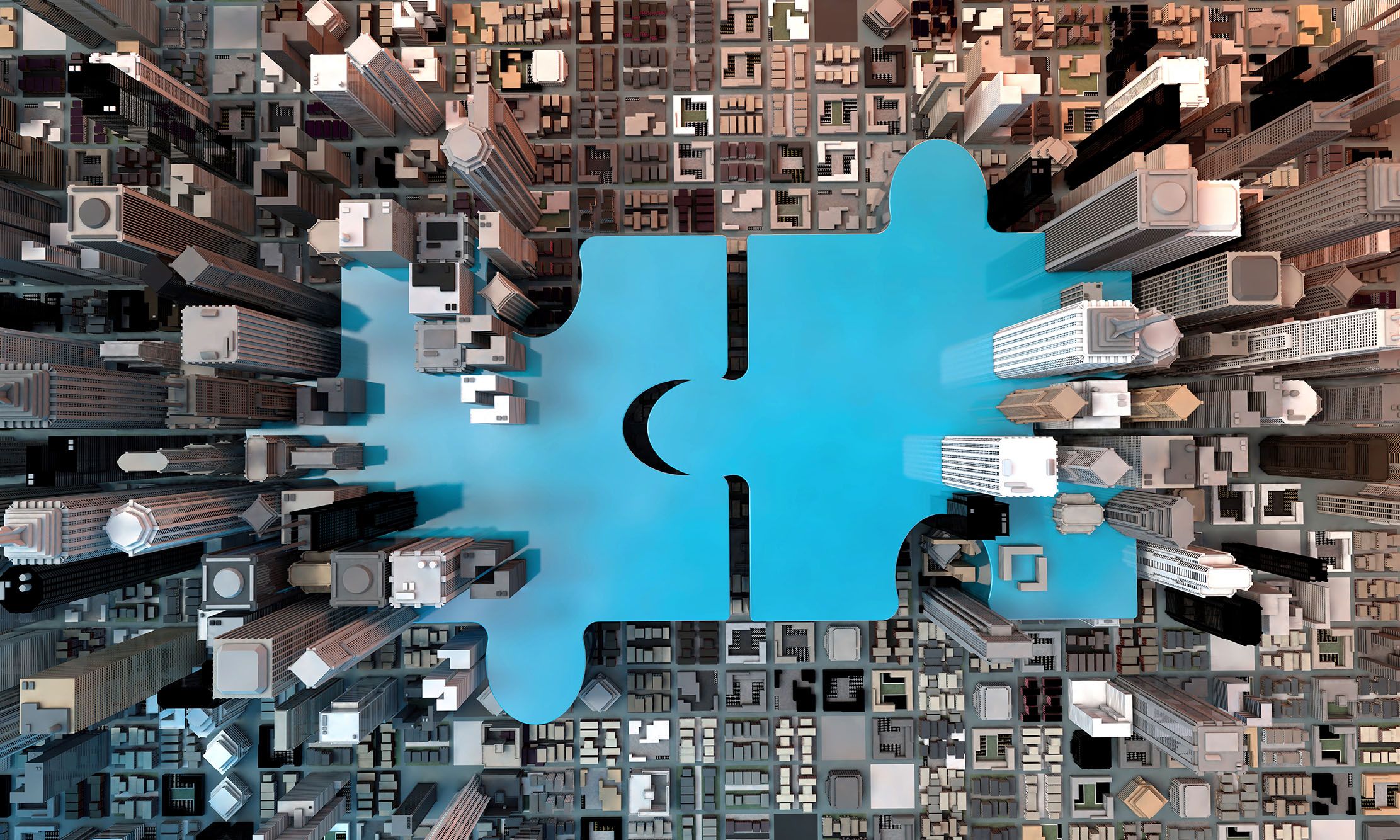

Lime will recycle bike and scooter batteries with Redwood Materials

Lime, the largest bike- and scooter-sharing company in the world, announced that it has struck a deal with Redwood Materials to recycle its lithium-ion batteries. Lime says its e-bike and e-scooter batteries typically last 500 charge cycles, or between five and seven years. Once those batteries reach their end of life, Lime will ship them […]

Lime, the largest bike- and scooter-sharing company in the world, announced that it has struck a deal with Redwood Materials to recycle its lithium-ion batteries.

Lime says its e-bike and e-scooter batteries typically last 500 charge cycles, or between five and seven years. Once those batteries reach their end of life, Lime will ship them to Redwood’s North Nevada recycling facility, where the first step will be to figure out how much of the battery is reusable, such as various connectors, wires, plastics, and other components.

After that, Redwood will begin a chemical recycling process, in which it strips out and refines the relevant elements like nickel, cobalt, and copper. Most of that refined material can then be reintegrated into the battery-making process. The company takes the materials and transforms them into “high-quality” battery materials that can then be sold back to its many partners to make new EV batteries. Around 95–98 percent of these materials are eventually recovered and returned to the supply chain, Redwood claims.

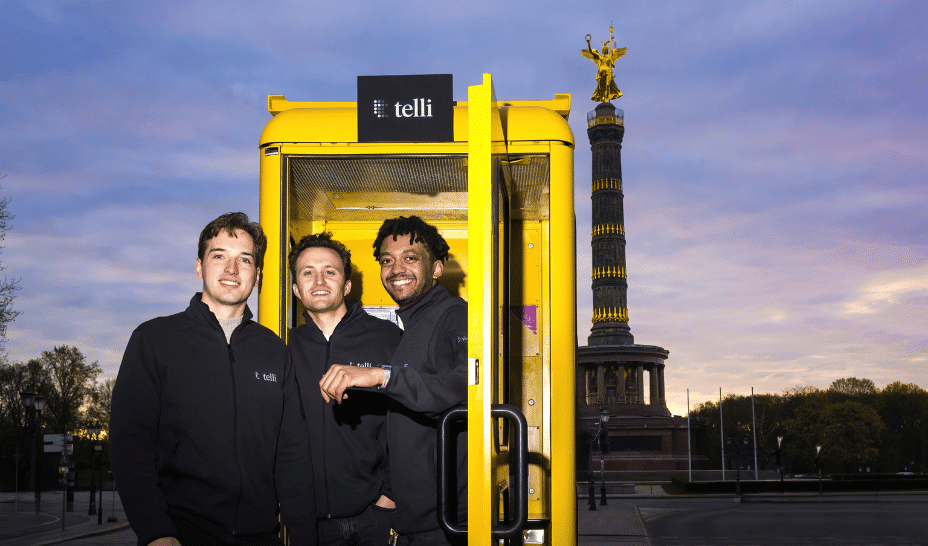

Lime says it was impressed by Redwood’s high recovery rates, which helped persuade the scooter sharing company to make a deal. The company plans on recycling its batteries from its shared bikes and scooters in just three countries: the US, Germany, and the Netherlands. Lime says it currently operates 270,000 shared vehicles in 30 countries.

“We’re in shared micromobility. So part of what we do, in essence, is a circular play,” said Lime’s head of sustainability, Andrew Savage. “Circularity of downstream, end of life batteries is quite similar, where we want to ensure that if a battery is no longer available for moving people around that we can get it back into the supply chain for its highest and best use.”

Redwood Materials was founded in 2017 by Jeffrey “JB” Straubel, a founder and former chief technology officer of Tesla. In addition to breaking down scrap from Tesla’s battery-making process with Panasonic, Redwood also recycles EV and e-bike batteries from Ford, Toyota, Nissan, BMW, GM, Rad Power Bikes, Specialized, Amazon, Lyft, and others.

“We’re in shared micromobility. So part of what we do, in essence, is a circular play.”

Redwood notes that each e-bike and scooter battery is around 0.5kWh, as compared to an EV battery, which is approximately 65kWh. Collecting around 130 so-called medium-format batteries provides enough recyclable material for one battery-electric vehicle.

Alexis Georgeson, VP for government relations at Redwood, called the effort to recycle medium-format batteries “a massive opportunity.”

“We recycled 20 gigawatt-hours worth of material just in 2024,” she said. “That’s enough to produce another 250,000 EVs. And that was spread across production scrap from the gigafactories to small consumer electronic devices, medium formats like these bikes and scooters, and then large-form EV packs and stationary storage.”

In terms of material production, Georgeson said Redwood’s focus is on cathode, which represents 60 percent of the cost of the battery. “We have produced anode copper foil and delivered it to partners like Panasonic already,” she said, “but are really turning our attention right now to just scaling and investing more in cathode.”

![[The AI Show Episode 144]: ChatGPT’s New Memory, Shopify CEO’s Leaked “AI First” Memo, Google Cloud Next Releases, o3 and o4-mini Coming Soon & Llama 4’s Rocky Launch](https://www.marketingaiinstitute.com/hubfs/ep%20144%20cover.png)

![Blue Archive tier list [April 2025]](https://media.pocketgamer.com/artwork/na-33404-1636469504/blue-archive-screenshot-2.jpg?#)

.png?#)

-Baldur’s-Gate-3-The-Final-Patch---An-Animated-Short-00-03-43.png?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

_Aleksey_Funtap_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

![Apple's Foldable iPhone May Cost Between $2100 and $2300 [Rumor]](https://www.iclarified.com/images/news/97028/97028/97028-640.jpg)

![Apple Releases Public Betas of iOS 18.5, iPadOS 18.5, macOS Sequoia 15.5 [Download]](https://www.iclarified.com/images/news/97024/97024/97024-640.jpg)

![Apple to Launch In-Store Recycling Promotion Tomorrow, Up to $20 Off Accessories [Gurman]](https://www.iclarified.com/images/news/97023/97023/97023-640.jpg)