Mastering Patch Management in OT, Overcoming Obstacles with Precision Solutions

The Growing Imperative of OT Patch Management Operational Technology (OT) underpins the world’s critical infrastructure, think power plants humming with electricity, water treatment facilities ensuring clean supply, or manufacturing lines churning out goods. These systems, driven by Industrial Control Systems (ICS), Supervisory Control and Data Acquisition (SCADA) setups, and IoT devices, are no longer isolated from the digital threats once reserved for IT networks. The convergence of IT and OT has opened new efficiencies but also new vulnerabilities. High-profile incidents, like the 2021 Colonial Pipeline ransomware attack, which disrupted fuel supply across the U.S. Southeast, spotlight the stakes: unpatched vulnerabilities in OT can cascade into real-world chaos. Patch management, the disciplined process of updating software to fix security flaws, stands as a frontline defense. Yet, in OT, it’s a high-wire act. Unlike IT, where a server reboot is routine, OT demands uninterrupted uptime, safety, and reliability. A single misstep in patching could halt a production line or endanger lives. This article unpacks the intricate challenges of patch management in OT environments and delivers precise, actionable solutions, tailored for engineers, security teams, and decision-makers navigating this critical domain. What Is Patch Management in OT? Patch management in OT is the systematic approach to identifying, evaluating, testing, deploying, and validating software updates (patches) that address vulnerabilities or bugs in systems like PLCs, HMIs (Human-Machine Interfaces), and IoT endpoints. It’s not just about slapping on a fix, it’s about ensuring these updates enhance security without compromising the operational heartbeat of critical infrastructure. The process sounds straightforward, but OT’s unique DNA complicates it. These systems prioritize availability over confidentiality, often run on decades-old hardware, and serve industries where downtime isn’t an option. Let’s break down the hurdles and explore how to tackle them. The Challenges: Why OT Patch Management Feels Like a Minefield 1. The Uptime Mandate OT systems don’t sleep. A steel mill’s furnace or a hospital’s HVAC system can’t pause for a patch without ripple effects, lost revenue, spoiled goods, or worse. Active vulnerability scans, a staple in IT, can overload OT networks, crashing delicate controllers. The challenge? Keeping systems secure without pulling the plug. 2. IT Tools in an OT World Most cybersecurity tools are forged for IT’s fast-paced, update-friendly ecosystem. OT, with its proprietary protocols and long-life assets, doesn’t play by those rules. An IT-grade patch management suite might flag vulnerabilities but choke on a SCADA system’s quirks, leaving security teams scrambling. 3. Sticker Shock and Overkill Enterprise-grade solutions often come with hefty price tags and bells-and-whistles irrelevant to a lean OT shop. A small water utility doesn’t need a $100,000 platform designed for multinational IT networks, it needs focused, affordable tools that fit its scale. 4. The Human Bottleneck Patching isn’t a “set it and forget it” task. It demands hands-on effort: tracking vendor releases, testing updates, and rolling them out. In OT, where staff juggle operational duties with security, this labor-intensive process often lags, widening the exposure window. 5. Safety First, Always A patch that fixes a flaw but breaks a safety interlock is a disaster waiting to happen. In OT, reliability isn’t negotiable, think chemical plants where a glitch could trigger a spill. The fear of unintended consequences makes teams hesitant, delaying critical updates. 6. Legacy Limbo OT is littered with relics, Windows XP machines, unsupported PLCs, and custom-built systems from the ‘90s. Vendors may have moved on, leaving no patches to apply. Replacing these dinosaurs is costly and disruptive, trapping operators in a security stalemate. 7. Regulatory Tightrope Regulations like NERC CIP (for utilities) or HIPAA (for healthcare) dictate strict patch timelines, assess within 35 days, deploy with care. Compliance adds pressure, but the rules don’t bend for OT’s operational realities, creating a tug-of-war between mandates and uptime. 8. Testing Nightmares Patches need a trial run before going live, but replicating an OT environment, complete with bespoke hardware and live data, is a logistical puzzle. A test bed might miss edge cases, and a botched patch could slip through, wreaking havoc. 9. No Room for Downtime Scheduled outages are rare in OT. A refinery might get a maintenance window once a year, hardly enough to keep pace with monthly patch cycles. This forces teams to weigh security against the clock, often deferring updates. 10. Asset Blind Spots You can’t patch what you don’t see. OT networks are a

The Growing Imperative of OT Patch Management

Operational Technology (OT) underpins the world’s critical infrastructure, think power plants humming with electricity, water treatment facilities ensuring clean supply, or manufacturing lines churning out goods. These systems, driven by Industrial Control Systems (ICS), Supervisory Control and Data Acquisition (SCADA) setups, and IoT devices, are no longer isolated from the digital threats once reserved for IT networks.

The convergence of IT and OT has opened new efficiencies but also new vulnerabilities. High-profile incidents, like the 2021 Colonial Pipeline ransomware attack, which disrupted fuel supply across the U.S. Southeast, spotlight the stakes: unpatched vulnerabilities in OT can cascade into real-world chaos.

Patch management, the disciplined process of updating software to fix security flaws, stands as a frontline defense. Yet, in OT, it’s a high-wire act. Unlike IT, where a server reboot is routine, OT demands uninterrupted uptime, safety, and reliability. A single misstep in patching could halt a production line or endanger lives. This article unpacks the intricate challenges of patch management in OT environments and delivers precise, actionable solutions, tailored for engineers, security teams, and decision-makers navigating this critical domain.

What Is Patch Management in OT?

Patch management in OT is the systematic approach to identifying, evaluating, testing, deploying, and validating software updates (patches) that address vulnerabilities or bugs in systems like PLCs, HMIs (Human-Machine Interfaces), and IoT endpoints. It’s not just about slapping on a fix, it’s about ensuring these updates enhance security without compromising the operational heartbeat of critical infrastructure.

The process sounds straightforward, but OT’s unique DNA complicates it. These systems prioritize availability over confidentiality, often run on decades-old hardware, and serve industries where downtime isn’t an option. Let’s break down the hurdles and explore how to tackle them.

The Challenges: Why OT Patch Management Feels Like a Minefield

1. The Uptime Mandate

OT systems don’t sleep. A steel mill’s furnace or a hospital’s HVAC system can’t pause for a patch without ripple effects, lost revenue, spoiled goods, or worse. Active vulnerability scans, a staple in IT, can overload OT networks, crashing delicate controllers. The challenge? Keeping systems secure without pulling the plug.

2. IT Tools in an OT World

Most cybersecurity tools are forged for IT’s fast-paced, update-friendly ecosystem. OT, with its proprietary protocols and long-life assets, doesn’t play by those rules. An IT-grade patch management suite might flag vulnerabilities but choke on a SCADA system’s quirks, leaving security teams scrambling.

3. Sticker Shock and Overkill

Enterprise-grade solutions often come with hefty price tags and bells-and-whistles irrelevant to a lean OT shop. A small water utility doesn’t need a $100,000 platform designed for multinational IT networks, it needs focused, affordable tools that fit its scale.

4. The Human Bottleneck

Patching isn’t a “set it and forget it” task. It demands hands-on effort: tracking vendor releases, testing updates, and rolling them out. In OT, where staff juggle operational duties with security, this labor-intensive process often lags, widening the exposure window.

5. Safety First, Always

A patch that fixes a flaw but breaks a safety interlock is a disaster waiting to happen. In OT, reliability isn’t negotiable, think chemical plants where a glitch could trigger a spill. The fear of unintended consequences makes teams hesitant, delaying critical updates.

6. Legacy Limbo

OT is littered with relics, Windows XP machines, unsupported PLCs, and custom-built systems from the ‘90s. Vendors may have moved on, leaving no patches to apply. Replacing these dinosaurs is costly and disruptive, trapping operators in a security stalemate.

7. Regulatory Tightrope

Regulations like NERC CIP (for utilities) or HIPAA (for healthcare) dictate strict patch timelines, assess within 35 days, deploy with care. Compliance adds pressure, but the rules don’t bend for OT’s operational realities, creating a tug-of-war between mandates and uptime.

8. Testing Nightmares

Patches need a trial run before going live, but replicating an OT environment, complete with bespoke hardware and live data, is a logistical puzzle. A test bed might miss edge cases, and a botched patch could slip through, wreaking havoc.

9. No Room for Downtime

Scheduled outages are rare in OT. A refinery might get a maintenance window once a year, hardly enough to keep pace with monthly patch cycles. This forces teams to weigh security against the clock, often deferring updates.

10. Asset Blind Spots

You can’t patch what you don’t see. OT networks are a patchwork of devices, some modern, some ancient, many non-standard. Traditional asset management tools falter here, missing critical endpoints and leaving gaps in the patching net.

The Solutions: Precision Strategies for OT Patch Mastery

1. See Everything with Automated Discovery

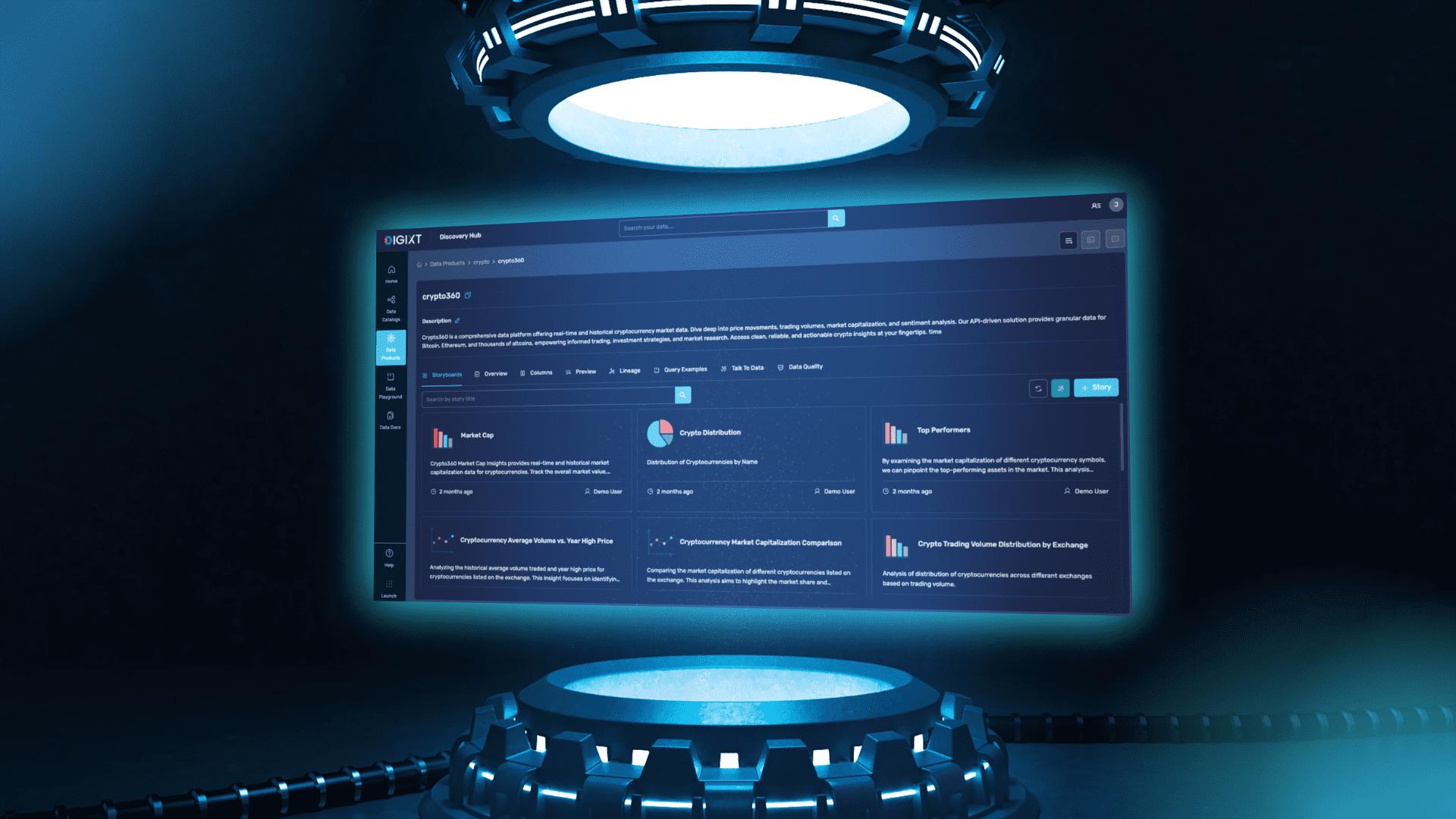

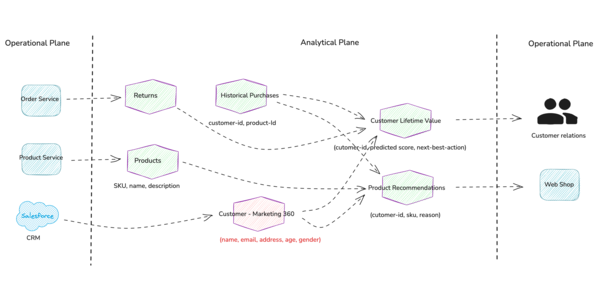

Start with visibility. Tools that auto-map OT assets, think Shieldworkz’s OT-specific platforms, cut through the fog. They catalog everything from Windows servers to obscure IoT sensors, giving you a live, accurate inventory. No more guesswork; you know what needs patching.

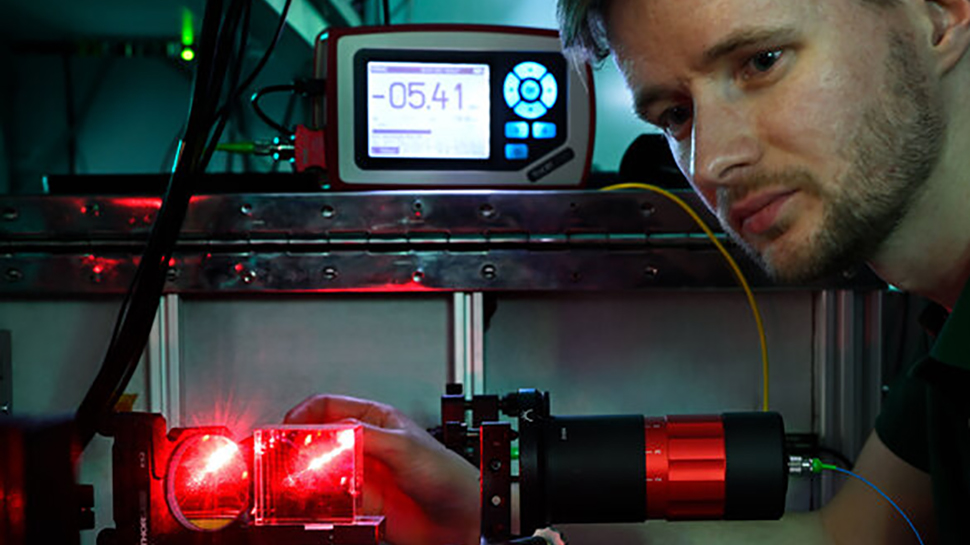

2. Listen, Don’t Shout: Passive Monitoring

Ditch active scans that rattle OT systems. Passive monitoring sniffs network traffic for anomalies, spotting vulnerabilities without touching a thing. It’s like a security whisperer, effective, unobtrusive, and safe for production.

3. Patch Smarter, Not Harder

Not every flaw is a five-alarm fire. Use threat intel to rank risks, focus on exploits in the wild or tied to critical assets. A chemical plant’s reactor controller trumps a back-office printer. Prioritization saves time and sanity.

4. Trust the Source

Vendor-validated patches are your safest bet. Manufacturers know their gear, stick to their updates to avoid compatibility headaches. Companies like Shieldworkz bridge this gap, curating patch feeds tailored for OT hardware.

5. Test Like It’s Live

Build a sandbox that mirrors your OT setup, same devices, same configs. Test patches here first, watching for glitches. It’s not cheap or easy, but it beats rolling the dice on a live system.

6. Time It Right

Sync patching with natural breaks, annual shutdowns, shift changes, or redundant system failovers. Hot patching (updates without reboots) is an option for some modern OT gear, minimizing disruption.

7. Layer Up When You Can’t Patch

Stuck with an unpatchable legacy box? Isolate it with network segmentation, harden its settings, or watch it with intrusion detection. These stopgaps buy time until a fix or replacement arrives.

8. Automate the Paperwork

Compliance doesn’t have to be a slog. Tools that log patch assessments and deployments, like those in Shieldworkz’s arsenal, map to standards like ISA/IEC 62443, keeping auditors happy without drowning staff in forms.

9. Empower Your People

Train OT crews on patching’s why and how. A technician who gets the stakes, say, a ransomware lockdown, won’t see it as “extra work.” Cross-train IT and OT teams to blend skills and lighten the load.

10. Partner with the Pros

Vendors and specialists are your allies. Regular check-ins with OEMs ensure timely patch drops, while OT security firms like Shieldworkz offer end-to-end support, from discovery to deployment, tailored to your industry.

Real-World Context: Lessons from the Field

Consider a mid-sized utility managing a regional power grid. In 2022, they faced a zero-day exploit targeting their SCADA software. Active scanning crashed a substation controller, forcing a manual restart mid-crisis. By switching to passive monitoring and a risk-based patch rollout, tested in a virtual twin of their grid, they patched the flaw during a low-demand window, averting disaster. Shieldworkz’s asset discovery tools helped them spot an overlooked IoT meter that was the initial breach point, proving visibility’s value.

Or take a pharmaceutical plant with a 20-year-old filling line. Vendor support ended in 2015, but replacement costs topped $2 million. They segmented the system, locked down its ports, and used passive monitoring to flag risks, buying time for a phased upgrade. These stories show that OT patching isn’t theoretical; it’s a gritty, practical fight won with strategy.

Standards as Your Compass

Frameworks like ISA/IEC 62443 offer a roadmap for OT security, with patch management as a core pillar. It pushes for risk assessments, testing rigor, and vendor sync-ups, principles that tame the chaos. NIST’s SP 800-40r4, though IT-leaning, adapts well to OT with its focus on lifecycle management. For regulated sectors, NERC CIP’s 35-day patch review clock keeps urgency front and center. Lean on these guides; they’re battle-tested.

The Bottom Line: Precision Beats Panic

Patch management in OT isn’t for the faint-hearted. It’s a balancing act, security versus stability, compliance versus uptime, modern threats versus aging tech. But it’s not about perfection; it’s about precision. Map your assets, prioritize your risks, test relentlessly, and lean on partners like Shieldworkz when the load gets heavy. The payoff? Resilient systems that keep the lights on, the water flowing, and the world turning, safely.

Cyber threats won’t wait. Neither should you. Master OT patching, and you master the art of thriving under pressure.

![[The AI Show Episode 145]: OpenAI Releases o3 and o4-mini, AI Is Causing “Quiet Layoffs,” Executive Order on Youth AI Education & GPT-4o’s Controversial Update](https://www.marketingaiinstitute.com/hubfs/ep%20145%20cover.png)

![[DEALS] Microsoft 365: 1-Year Subscription (Family/Up to 6 Users) (23% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

![From Art School Drop-out to Microsoft Engineer with Shashi Lo [Podcast #170]](https://cdn.hashnode.com/res/hashnode/image/upload/v1746203291209/439bf16b-c820-4fe8-b69e-94d80533b2df.png?#)

(1).jpg?#)

_Inge_Johnsson-Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

![Apple to Split iPhone Launches Across Fall and Spring in Major Shakeup [Report]](https://www.iclarified.com/images/news/97211/97211/97211-640.jpg)

![Apple to Move Camera to Top Left, Hide Face ID Under Display in iPhone 18 Pro Redesign [Report]](https://www.iclarified.com/images/news/97212/97212/97212-640.jpg)

![Apple Developing Battery Case for iPhone 17 Air Amid Battery Life Concerns [Report]](https://www.iclarified.com/images/news/97208/97208/97208-640.jpg)

![AirPods 4 On Sale for $99 [Lowest Price Ever]](https://www.iclarified.com/images/news/97206/97206/97206-640.jpg)

![[Updated] Samsung’s 65-inch 4K Smart TV Just Crashed to $299 — That’s Cheaper Than an iPad](https://www.androidheadlines.com/wp-content/uploads/2025/05/samsung-du7200.jpg)