❓Question: How can sandblasting operators stay safe and healthy at work?

Sandblasting is a critical process in machining, mold manufacturing, and surface finishing — but it also poses serious risks if not properly managed. To ensure worker health and safety during abrasive blasting operations, companies must focus on equipment upgrades, personal protection, and environmental controls. Here are 5 key measures every manufacturing facility should adopt: ✅ 1. Use Enclosed Sandblasting Systems with Industrial Dust Collectors Choose enclosed blast cabinets or automated blasting machines to prevent abrasive rebound and airborne particle exposure. Combine with HEPA-grade dust collectors (≥99.97% efficiency) to drastically reduce inhalable particulate matter (PM2.5/PM10) in the workspace. ✅ 2. Provide Certified Personal Protective Equipment (PPE) All sandblasting operators should wear: Positive-pressure respirator helmets (or air-fed hoods compliant with OSHA/NIOSH or GB standards) Abrasion-resistant coveralls, cut-proof gloves, and steel-toe boots Hearing protection — especially in high-noise blasting environments ✅ 3. Choose Low-Dust, Eco-Friendly Blasting Media Switch to ceramic beads, stainless steel shots, or glass beads, which generate far less dust than traditional abrasives. Avoid silica sand, as prolonged exposure can lead to silicosis and other chronic respiratory issues. ✅ 4. Standardize Operating Procedures & Train Operators Develop detailed Standard Operating Procedures (SOPs) covering: Equipment start-up/shutdown Correct nozzle angle, pressure, and distance Daily maintenance and inspection checklists Regular training sessions improve both safety awareness and operating consistency. ✅ 5. Monitor Work Environment and Schedule Health Checkups Install real-time dust and noise monitors in blasting areas to stay within occupational exposure limits. Offer annual lung X-rays and hearing tests to frontline workers to ensure early detection and intervention of health risks. ✅ Conclusion: To protect workers in sandblasting operations, companies must address equipment safety, material selection, personal protection, standardized processes, and environmental monitoring. A comprehensive "man–machine–environment–management" framework ensures both operational efficiency and long-term worker health.

Sandblasting is a critical process in machining, mold manufacturing, and surface finishing — but it also poses serious risks if not properly managed. To ensure worker health and safety during abrasive blasting operations, companies must focus on equipment upgrades, personal protection, and environmental controls.

Here are 5 key measures every manufacturing facility should adopt:

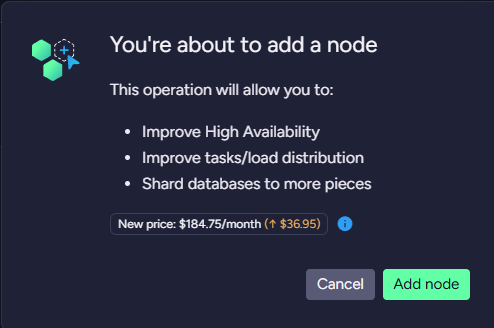

✅ 1. Use Enclosed Sandblasting Systems with Industrial Dust Collectors

Choose enclosed blast cabinets or automated blasting machines to prevent abrasive rebound and airborne particle exposure. Combine with HEPA-grade dust collectors (≥99.97% efficiency) to drastically reduce inhalable particulate matter (PM2.5/PM10) in the workspace.

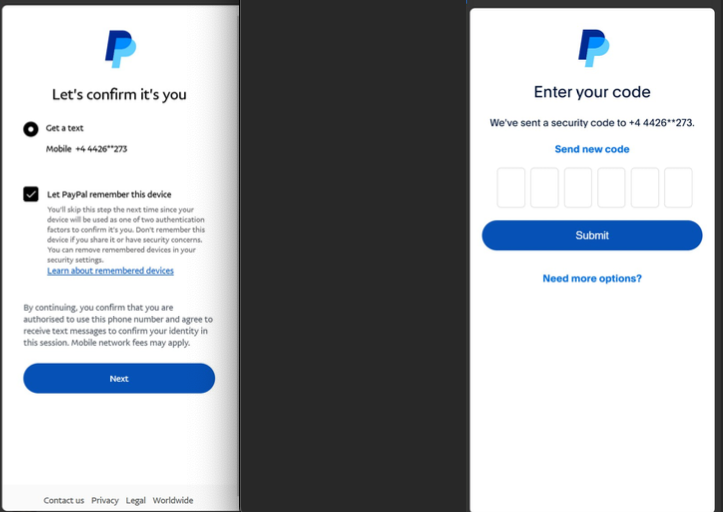

✅ 2. Provide Certified Personal Protective Equipment (PPE)

All sandblasting operators should wear:

Positive-pressure respirator helmets (or air-fed hoods compliant with OSHA/NIOSH or GB standards)

Abrasion-resistant coveralls, cut-proof gloves, and steel-toe boots

Hearing protection — especially in high-noise blasting environments

✅ 3. Choose Low-Dust, Eco-Friendly Blasting Media

Switch to ceramic beads, stainless steel shots, or glass beads, which generate far less dust than traditional abrasives. Avoid silica sand, as prolonged exposure can lead to silicosis and other chronic respiratory issues.

✅ 4. Standardize Operating Procedures & Train Operators

Develop detailed Standard Operating Procedures (SOPs) covering:

Equipment start-up/shutdown

Correct nozzle angle, pressure, and distance

Daily maintenance and inspection checklists

Regular training sessions improve both safety awareness and operating consistency.

✅ 5. Monitor Work Environment and Schedule Health Checkups

Install real-time dust and noise monitors in blasting areas to stay within occupational exposure limits. Offer annual lung X-rays and hearing tests to frontline workers to ensure early detection and intervention of health risks.

✅ Conclusion:

To protect workers in sandblasting operations, companies must address equipment safety, material selection, personal protection, standardized processes, and environmental monitoring. A comprehensive "man–machine–environment–management" framework ensures both operational efficiency and long-term worker health.

![[The AI Show Episode 144]: ChatGPT’s New Memory, Shopify CEO’s Leaked “AI First” Memo, Google Cloud Next Releases, o3 and o4-mini Coming Soon & Llama 4’s Rocky Launch](https://www.marketingaiinstitute.com/hubfs/ep%20144%20cover.png)

![[DEALS] The All-in-One Microsoft Office Pro 2019 for Windows: Lifetime License + Windows 11 Pro Bundle (89% off) & Other Deals Up To 98% Off](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

![Is this too much for a modular monolith system? [closed]](https://i.sstatic.net/pYL1nsfg.png)

_Andreas_Prott_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

![What features do you get with Gemini Advanced? [April 2025]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2024/02/gemini-advanced-cover.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Apple Shares Official Trailer for 'Long Way Home' Starring Ewan McGregor and Charley Boorman [Video]](https://www.iclarified.com/images/news/97069/97069/97069-640.jpg)

![Apple Watch Series 10 Back On Sale for $299! [Lowest Price Ever]](https://www.iclarified.com/images/news/96657/96657/96657-640.jpg)

![EU Postpones Apple App Store Fines Amid Tariff Negotiations [Report]](https://www.iclarified.com/images/news/97068/97068/97068-640.jpg)

![Apple Slips to Fifth in China's Smartphone Market with 9% Decline [Report]](https://www.iclarified.com/images/news/97065/97065/97065-640.jpg)