Linear Programming: Managing Multiple Targets with Goal Programming

Part 6: Balancing multiple objectives using the weights and preemptive goal programming approaches The post Linear Programming: Managing Multiple Targets with Goal Programming appeared first on Towards Data Science.

This is the

By the end of this article, you’ll understand:

1. Definition of goal programming and when it should be used

2. The weighted goal programming approach — illustrated with an example

3. The preemptive goal programming approach — illustrated with an example

Definition and Use Case of Goal Programming

Goal programming is a special case of linear programming that allows for multiple — often conflicting — objectives to be balanced. With regular LP problems, you pick a single metric to optimize (minimize or maximize) and set constraints to ensure that the optimal solution is feasible. Goal programming is a technique that allows for multiple objective metrics to be targeted at the same time.

The ‘mindset’ of goal programming is fundamentally different from plain vanilla LP problems. Basic LP searches for ways to get as little or as much of a single metric as possible — e.g., maximize profit or minimize waste — subject to constraints. Often conflicting priorities will be found in the objective function or the constraints. For example, maximize profit (objective) subject to a maximum amount of waste (constraint). With goal programming, we can move important constraint metrics into the objective function so we can optimize on them rather than just constraining them. We can maximize profit and minimize waste at the same time!

Now is a good time to establish the example we will explore for the rest of the article:

Let’s imagine that we manage a factory that makes clothing. Our factory can make pants, shirts, and dresses. Each article of clothing has costs, profit, and waste associated with their production. We want to create a production plan that will make a certain level of profit and also waste below a certain quantity due to an environmental commitment. Let’s say that we want to make $150k a month in profit and we also want to waste less than 20k yards of fabric. In addition to our goals, we can’t spend more than $50k in materials and labor.

The example above sounds a lot like a regular linear programming problem right? Well, the twist is that we can’t make $150k in profit and waste less than 20k of yards at the same time. In other words, there would be no feasible solution if we were to plug this into a regular linear programming problem. Typically, the goals set in the problems cannot all be achieved with a single solution, otherwise there wouldn’t be a point in using goal programming. We would just use regular old linear programming with our goals as constraints. The real value of goal programming is that it can create a compromise between conflicting goals when regular linear programming would yield an infeasible solution.

The real value of goal programming is that it can create a compromise between conflicting goals when regular linear programming would yield an infeasible solution.

How does goal programming balance and compromise with conflicting goals? There are two popular approaches: (1) weighted and (2) preemptive. We’ll cover these in detail in the following sections.

The weights approach

Here, we’ll dive into the details of the weights approach. The weights method has a single objective function and runs a single Optimization based on (you guessed it) weights! The fact that only one optimization is run under the weights method may seem like a given — but the preemptive method actually runs multiple linear programming optimizations. We’ll get to that in the next section…

The weights method has specific targets or goals for multiple metrics — e.g., make at least $150k in profit selling clothes or waste no more than 20k yards of fabric. For regular LP, we want to fully optimize. For the weights method of goal programming, we want to get as close to hitting goals as possible — after we reach a goal, the optimization doesn’t see more benefit in further maximization or minimization, so it prioritizes hitting the next most important goal. If this seems confusing now, don’t worry it will make more sense as we get into the example.

The objective function for the weights approach is specially formulated to minimize the weighted differences between a metric’s goal and the actual value of the metric. Let’s jump to our example from above — i.e., we want to make $150k in profit and waste less than 20k yards of raw material. Our objective is to minimize how far off we are from both of these goals.

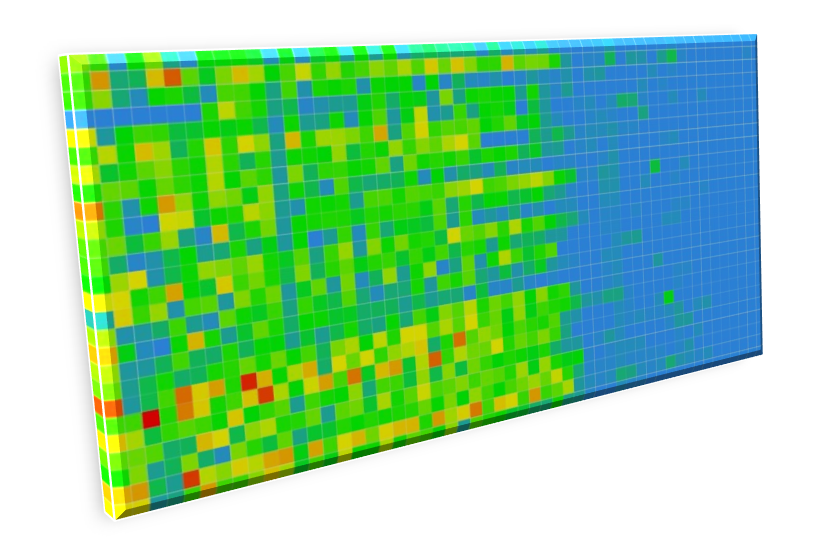

Here is the mathematical formulation for this objective:

With our objective function set up, we need to define our constraints. We will have two types of constraints (1) goal related constraints and (2) regular linear programming constraints (the same kind of constraints you would find in plain vanilla LP). Let’s talk about the goal related constraints first.

We will need to create two things to set up our goal related constraints, (1) profit and waste functions and (2) multiple slack variables. Let’s go through these one at a time.

The profit and waste functions are very straight forward. They combine our decision variables together to calculate total profit and total waste give a specific solution. Below are the formulas that tie profit and waste to the number of pants, shirts and dresses we produce:

With our profit and waste functions established, let’s start talking about our slack variables. In goal programming, slack variables are used to measure how far a solution is from hitting a goal. In our example, the variables P and W are both slack variables — they represent how much lower our profit is compared to our profit goal and how much higher our waste is compared to our waste goal. Slack variables are embedded in constraints. Below are the constraint functions for our profit and waste goals — again, the P’s and the W’s are our slack variables:

Note that we have plus and minus slack variables — this allows us to miss the goal on either end. We only want to penalize the slack variable that goes in the opposite direction of our goal (e.g., we don’t want to penalize more profit than our goal, we only want to penalize less profit) — that is why only one slack variable per goal is in the objective function. With this new notation, let’s rewrite our objective function:

We have now done all of the special work for goal programming. The last thing we need to do is quickly add our plain vanilla budget constraint. We are using a regular constraint for our budget because, in our example, it is a hard constraint. Unlike with profit and waste, we cannot violate the budget.

Now, we have a fully specified goal programming problem. Let’s set it up in Python and solve!

# $150,000 in profit

problem += profit + profit_deviation_neg - profit_deviation_pos == 150000, "Profit_Goal"

# Waste goal: No more than 20,000 yards of waste

problem += waste + waste_deviation_neg - waste_deviation_pos == 20000, "Cost_Goal"

# Budget constraint

problem += cost <= 50000

# Solve the problem

problem.solve()

# Display the results

print("Status:", pulp.LpStatus[problem.status])

print("Pants produced:", pulp.value(pants))

print("Shirts produced:", pulp.value(shirts))

print("Dresses produced:", pulp.value(dresses))

print("Cost :", pulp.value(cost))

print("Profit :", pulp.value(profit))

print("Profit deviation (positive):", pulp.value(profit_deviation_pos))

print("Profit deviation (negative):", pulp.value(profit_deviation_neg))

print("Waste :", pulp.value(waste))

print("Waste deviation (positive):", pulp.value(waste_deviation_pos))

print("Waste deviation (negative):", pulp.value(waste_deviation_neg))This optimization recommends we make 0 pants, 5,000 shirts and 0 dresses. We make $150k in profit which matches our goal exactly and we waste 50k yards of fabric which exceeds our max waste by 30k yards. The full results are printed by the code and shown below:

Now that we’ve got the basic structure of the weights approach down, let’s actually talk about the weights! In our first example, we gave equal weights to a dollar of profit and to a yard of waste. This probably doesn’t make a lot of sense because they are different units. Setting the weights is a subjective decision to be made by the practitioner. For our example, we’ll decide that wasting 1.5 yards of fabric is as bad as making $1 of profit is good. In other words, we’ll increase the weight of fabric waste to 1.5 in our objective function.

problem += profit_deviation_neg + 1.5*waste_deviation_posThe optimization with the updated rates recommends we make about 8,572 pants, 7,143 shirts and 0 dresses. With this solution, we generate $107k in profit (which is a goal miss of $43k) and we waste 20,000 yards of fabric which matches our goal exactly. The full results are printed by the code and shown below:

Clearly, shifting the weights of the goals can have large impact on the optimization results. We need to carefully set our weights to adequately balance the relative importance of our goals!

Now that we have a solid understanding of how the weighted approach works, let’s shift to talking about the goal programming with the preemptive approach.

Preemptive Approach

While the weights method balances goals using weights in the objective function, the preemptive method gives hierarchical priority to goals through iterative optimizations. That’s a lot of words, don’t worry, we’ll break it down!

Here are the steps to the preemptive approach:

1. Run a regular linear programming optimization on your first goal — e.g., maximize profit

2. Save the objective value from that run

3. Run another regular linear programming on the next most important goal — e.g., minimize waste — but, add the objective value from the last run as a constraint

4. Repeat the process until you have gone through all goal metrics

Two important features of the preemptive method are (1) it prioritizes goals by rank and (2) the objective value of a higher importance goal cannot be decreased (because of the hard constraint) when optimizing lower priority goals. Let’s go over an example to build intuition.

For our example, let’s say that profit is the most important goal and minimizing waste is the second. We’ll start out by running a plain vanilla optimization that maximizes profit:

# Define the problem

problem = pulp.LpProblem("Clothing_Company_Goal_Programming", pulp.LpMaximize)

# Decision variables: number of pants, shirts, and dresses produced

pants = pulp.LpVariable('pants', lowBound=0, cat='Continuous')

shirts = pulp.LpVariable('shirts', lowBound=0, cat='Continuous')

dresses = pulp.LpVariable('dresses', lowBound=0, cat='Continuous')

# Profit and cost coefficients

profit = 10 * pants + 3 * shirts + 15 * dresses

cost = 5 * pants + 1 * shirts + 10 * dresses

waste = 1.5 * pants + 1 * shirts + 3 * dresses

# Objective function: Maximize profit

problem += profit

# Constraints

# Budget constraint

problem += cost <= 50000

# Solve the problem

problem.solve()

# Display the results

print("Status:", pulp.LpStatus[problem.status])

print("Pants produced:", pulp.value(pants))

print("Shirts produced:", pulp.value(shirts))

print("Dresses produced:", pulp.value(dresses))

print("Cost :", pulp.value(cost))

print("Profit :", pulp.value(profit))The results of the profit maximizing LP problem are below:

So, our objective function says to make 50k shirts and collect a profit of $150k. This was only the first optimization we are going to run though! Following the algorithm outlined above, we will now run another LP that minimizes waste but, we will add a constraint of profit ≥ $150k to ensure we don’t get a worse profit.

# Define the problem

problem = pulp.LpProblem("Clothing_Company_Goal_Programming", pulp.LpMinimize)

# Decision variables: number of pants, shirts, and dresses produced

pants = pulp.LpVariable('pants', lowBound=0, cat='Continuous')

shirts = pulp.LpVariable('shirts', lowBound=0, cat='Continuous')

dresses = pulp.LpVariable('dresses', lowBound=0, cat='Continuous')

# Profit and cost coefficients

profit = 10 * pants + 3 * shirts + 15 * dresses

cost = 5 * pants + 1 * shirts + 10 * dresses

waste = 1.5 * pants + 1 * shirts + 3 * dresses

# Objective function: Minimize the fabric waste

problem += waste

# Budget constraint

problem += cost <= 50000

problem += profit >= 150000

# Solve the problem

problem.solve()

# Display the results

print("Status:", pulp.LpStatus[problem.status])

print("Pants produced:", pulp.value(pants))

print("Shirts produced:", pulp.value(shirts))

print("Dresses produced:", pulp.value(dresses))

print("Cost :", pulp.value(cost))

print("Profit :", pulp.value(profit))And here are the results of this final optimization:

The astute observer will notice that the optimization is the exact same  Read More

Read More

%20Abstract%20Background%20112024%20SOURCE%20Amazon.jpg)

![[The AI Show Episode 142]: ChatGPT’s New Image Generator, Studio Ghibli Craze and Backlash, Gemini 2.5, OpenAI Academy, 4o Updates, Vibe Marketing & xAI Acquires X](https://www.marketingaiinstitute.com/hubfs/ep%20142%20cover.png)

-Nintendo-Switch-2-–-Overview-trailer-00-00-10.png?width=1920&height=1920&fit=bounds&quality=80&format=jpg&auto=webp#)

_Anna_Berkut_Alamy.jpg?#)

![YouTube Announces New Creation Tools for Shorts [Video]](https://www.iclarified.com/images/news/96923/96923/96923-640.jpg)

![[Weekly funding roundup March 29-April 4] Steady-state VC inflow pre-empts Trump tariff impact](https://images.yourstory.com/cs/2/220356402d6d11e9aa979329348d4c3e/WeeklyFundingRoundupNewLogo1-1739546168054.jpg)