Why the Biggest Name in Lithium Batteries Is Betting Against Lithium?

In a move that’s sending shockwaves across the energy storage industry, CATL (Contemporary Amperex Technology Co. Limited) — the...

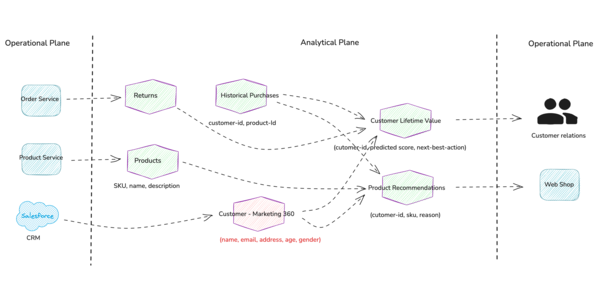

In a move that’s sending shockwaves across the energy storage industry, CATL (Contemporary Amperex Technology Co. Limited) — the world’s largest lithium battery manufacturer — is pivoting towards sodium-ion battery technology. Despite holding a dominant 37.9% share of the global EV battery market in 2024, according to CNEVPost, CATL believes that up to half the battery market could shift to sodium-based systems. In a November 2024 interview with Reuters, CATL's co-founder Robin Zeng emphasized that sodium-ion batteries are a better bet than solid-state ones. CATL’s new sodium-ion battery, branded Naxtra, will enter mass production in December 2025 and is expected to offer an energy density of 175 Wh/kg — comparable to today's lithium iron phosphate (LFP) batteries. This strategic shift signals not just a diversification move for CATL, but possibly the start of a major transformation in global energy storage.

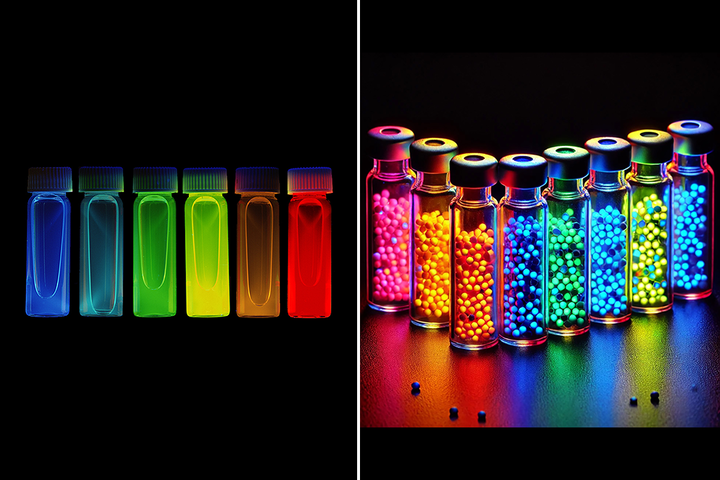

Sodium-Ion: The Salty Contender

While sodium-ion battery (SIB) technology has been around for decades, improvements in chemistry and manufacturing techniques have revitalized its prospects. Sodium, unlike lithium, is abundant and inexpensive, with a global supply that’s nearly inexhaustible — think oceans full of it. Extraction is simpler and far less destructive than lithium mining, positioning sodium-ion as a more sustainable alternative. Although sodium-ion batteries still lag behind their lithium-ion cousins in terms of energy density — with top-performing sodium cells achieving around 200 Wh/kg versus lithium-ion’s 300 Wh/kg — the cost, safety, and environmental advantages are compelling enough for major companies to start placing big bets on the technology.

Global Giants Embrace Sodium

CATL is not alone in this race. Its closest rival, BYD, which held a 17.2% share of the global EV battery market in 2024 (as per CNEVPost), has also thrown its hat into the sodium-ion ring. BYD broke ground on a massive $1.4 billion sodium-ion battery plant in Xuzhou, China, aiming for an annual production capacity of 30 GWh by 2027, according to Power Technology. BYD’s strategy focuses on using these batteries in electric scooters, microcars, and other applications where slightly lower energy density is acceptable. Meanwhile, in the United States, California-based Natron Energy is investing $1.4 billion to build a sodium-ion battery factory in Kingsboro, North Carolina. As reported by Utility Dive, this facility will have an annual output of 24 GWh, making it one of the largest sodium-ion battery projects outside China.

Innovations and Breakthroughs

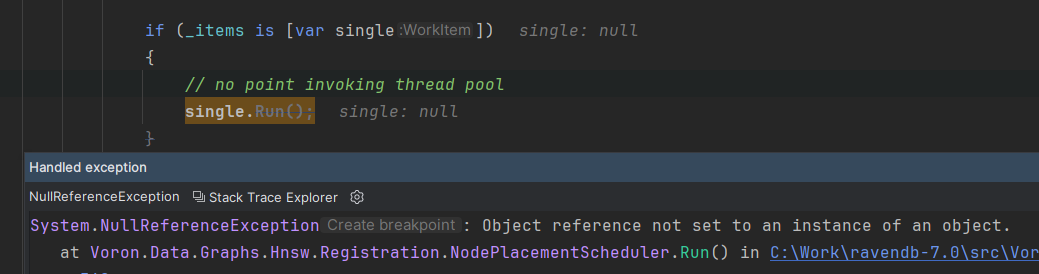

Beyond scaling up production, innovations in materials science are pushing sodium-ion batteries further. Researchers at the Dincă Lab in the U.S. have developed an organic cathode material called bis-tetraaminobenzoquinone (TAQ), which offers high energy and power densities at a fraction of the cost of traditional metal-based cathodes. According to a report from Princeton University Chemistry Department, this material could significantly boost sodium-ion performance while keeping costs low. Swedish battery manufacturer Northvolt also unveiled its sodium-ion technology in late 2023, achieving a respectable 160 Wh/kg. However, Northvolt faced financial headwinds, filing for Chapter 11 restructuring in late 2024 — a reminder that technological breakthroughs must be paired with financial stability to succeed.

Weighing the Pros and Cons

Sodium-ion batteries offer several key advantages. First, the raw materials — primarily salt — are far cheaper and easier to source than lithium. Second, sodium batteries demonstrate excellent safety profiles, with a much lower risk of thermal runaway, making them attractive for stationary storage systems like solar farms and backup grids. Third, sodium-ion batteries outperform lithium-ion systems in cold climates, a significant advantage for regions facing sub-zero conditions. However, there are still significant drawbacks. Sodium-ion batteries generally have lower energy densities, meaning they are heavier and bulkier compared to their lithium counterparts. While manufacturing costs per cell may be lower, the cost per unit of stored energy can end up being higher due to the increased volume and weight. Furthermore, the sodium-ion supply chain is still in its infancy, lacking the massive economies of scale that lithium has enjoyed for over two decades.

The Road Ahead

Despite the challenges, sodium-ion batteries appear to be on a fast track to commercial relevance. With heavyweights like CATL, BYD, and Natron Energy investing billions into scaling and improving the technology, sodium-ion batteries are no longer just a lab curiosity. Analysts project that sodium-ion batteries could occupy 20% to 40% of the stationary storage and two-wheeler EV markets by 2030 if current development trends continue. However, the lithium market is not standing still. Lithium prices have dropped nearly 70% over the past three years, according to Trading Economics, reducing the immediate financial advantage of sodium batteries.

Economists and battery chemists alike, including Dan Steingart of Columbia University, caution that sodium-ion manufacturers will struggle until they achieve economies of scale. A Stanford University study published in January 2025 further emphasized that while sodium-ion offers promise, its path to cost competitiveness remains uncertain. Yet compared to other emerging battery technologies still stuck in university labs, sodium-ion is already rolling off assembly lines, making it one of the most credible challengers to lithium's dominance.

Sodium-ion batteries are still climbing the learning curve, but their commercial readiness level — especially for grid-scale applications — is arguably at 8 or 9 out of 10. They may not dethrone lithium anytime soon, but they could carve out a major, lasting place in the global battery ecosystem. In a market traditionally allergic to change, sodium-ion might just be the "seasoning" the energy sector needs.

![[The AI Show Episode 143]: ChatGPT Revenue Surge, New AGI Timelines, Amazon’s AI Agent, Claude for Education, Model Context Protocol & LLMs Pass the Turing Test](https://www.marketingaiinstitute.com/hubfs/ep%20143%20cover.png)

![[DEALS] Koofr Cloud Storage: Lifetime Subscription (1TB) (80% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

.jpg?#)

_Muhammad_R._Fakhrurrozi_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

_NicoElNino_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

![M4 MacBook Air Drops to Just $849 - Act Fast! [Lowest Price Ever]](https://www.iclarified.com/images/news/97140/97140/97140-640.jpg)

![Apple Smart Glasses Not Close to Being Ready as Meta Targets 2025 [Gurman]](https://www.iclarified.com/images/news/97139/97139/97139-640.jpg)

![iPadOS 19 May Introduce Menu Bar, iOS 19 to Support External Displays [Rumor]](https://www.iclarified.com/images/news/97137/97137/97137-640.jpg)