This Simplehuman tequila isn’t a gimmick—it shows the full range of agave the brand is upcycling into sponges

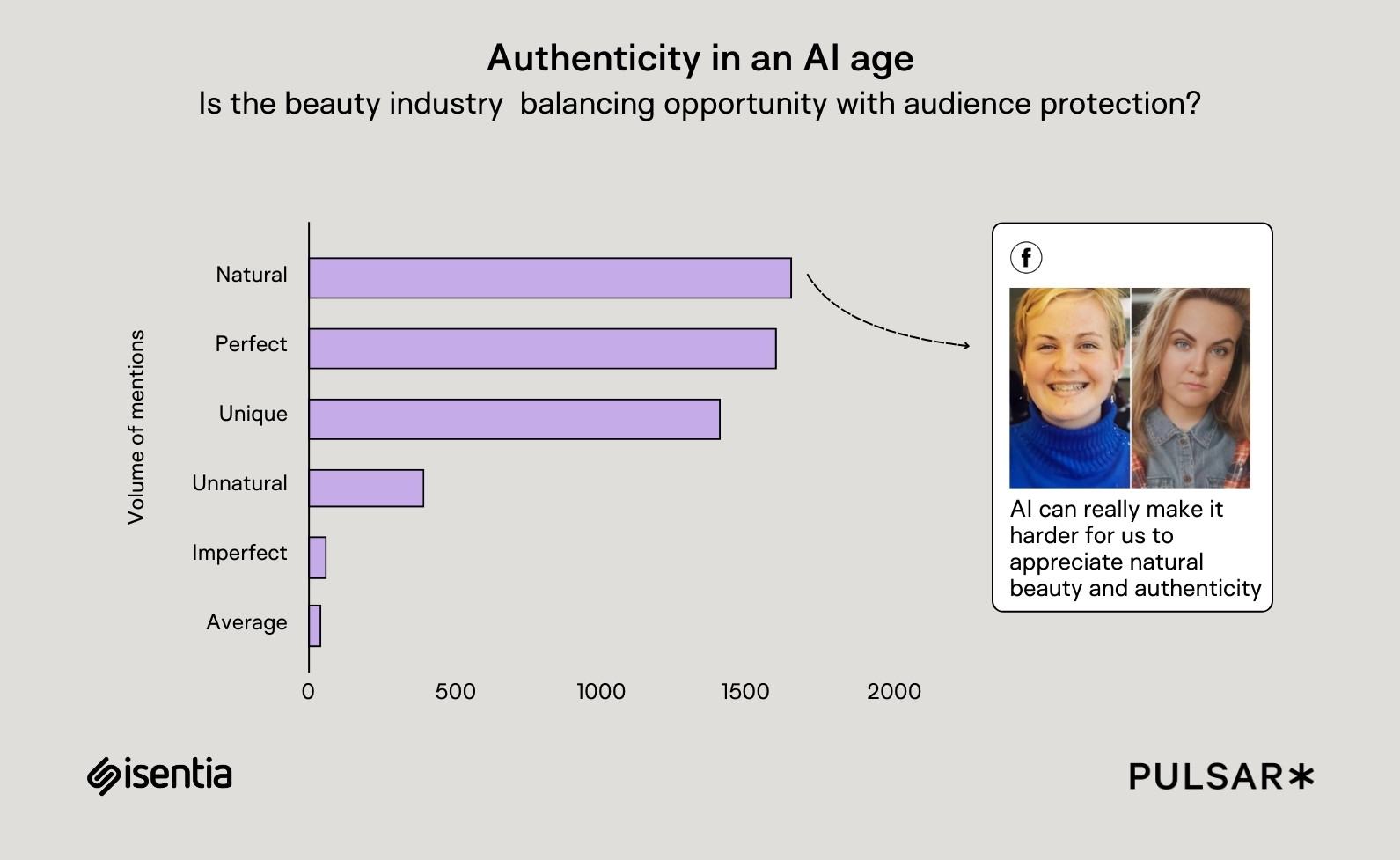

Design-minded home goods brand Simplehuman recently released a product that’s a little out of its wheelhouse—a limited-edition tequila with distillery Nosotros. It may be the company’s first foray into spirits, but the brand already knows how to work with the Weber blue agave that made the tequila. The agave fibers on Simplehuman’s Soapwell sponge begin their life cycle by being pressed into Nosotros tequila at the company’s distillery in Tequila, Mexico. Nosotros then supplies its leftover agave fibers to Simplehuman. The $100 Nosotros x Simplehuman Blanco tequila is made out of that same agave, and was released to mark a year that Simplehuman has been spinning the fibers into sponges. [Photo: Simplehuman] Simplehuman CEO Frank Yang says the company approached the tequila the same way it does any product—and notes that the agave-sourcing partnership shows off the “less is more” approach that guides both brands. “We’re trying to create cool things that exist in the world that people would miss if we weren’t doing this,” Yang says. [Photo: Simplehuman] High proof, high performance The story of how tequila ingredients became a kitchen product isn’t too complicated. It starts with Yang’s fondness for tequila. While on vacation in Mexico in 2022, he joined a tequila-making class and learned how agave is used to make the spirit. “They were telling me how the fiber is really tough,” he says, noting that after the juice was extracted, “it seemed like they were throwing the [pulp] away.” The Simplehuman R&D team was both skeptical and excited. It was a tricky process, working with jimadores (farmers who harvest agave plants in Mexico) to handpick specific fibers amid the gunky pulp. But after about eight months, they realized it was a solution that could help create a soft sponge that could also scrub without scratching pots and pans. “High performance is the most important,” he says. Besides the agave fibers, the sponge’s differentiator is a round reservoir—the sponge’s eponymous soap well. “[The soap] seeps down to the sponge so it doesn’t just wash away,” Yang says. The circular well is positioned to match where soap comes out of a Simplehuman soap dispenser, and also has a hard outer ring that can offer a deeper scrub for stubborn residue. [Photo: Simplehuman] A tequila influenced by terrain Nosotros approaches tequila like wine—each spirit taking on unique characteristics based on the land where its agave grows. The Nosotros x Simplehuman bottle of additive-free Blanco tequila is not made differently than Nosotros’s other bottles of Blanco, but is a particular vintage. Nosotros cofounder Carlos Soto describes this specific Simplehuman vintage as mineral-forward. “A lot of times with our Blanco, we’ve had the highlands carry a lot of it—more fruity notes and that cooked agave sweetness,” he says. He’s referring to the Mexican highlands of Arasco, Jalisco, where 50% of the agave for Nosotros tequila comes from. The other 50% comes from the city of Tequila, located in the lowlands of Jalisco, and comes across as more dominant in this vintage. “Lowlands usually have a lot more shade. . . . They tend to have soil that is very rich,” Soto says. “They become a little bit more peppery, more earthy.” The approach that Nosotros takes of utilizing these two agaves not only provides a more balanced taste across its line of additive-free products, but also reduces stress on the environment. “The farms that we work with are able to rotate crops a little bit more just because we’re only using 50% from each,” Soto says. “It really protects the soil, which keeps the quality of the agave.” The amount of agave required to yield one bottle of tequila produces enough fibers to make more than 2,000 sponges. Giving agave fibers a second life Soto says he thinks of Nosotros as an agave company, and he is always searching for ways to utilize agave fibers. Even before the Simplehuman partnership, Nosotros used fibers to create the labels on all of its bottles, and often recycles the fibers as fertilizer. But the company still regularly has a surplus. “We struggle to allocate [the remaining fibers] sometimes,” Soto says. “We don’t want to just throw it in a landfill.” Simplehuman is Nosotros’s first agave brand partner, and it sees more opportunity to work with other brands to give agave a second life. “There’s so much tequila being produced right now, Soto says. “There are more fibers than people who are taking it.” The company is in the early stages of creating a bigger market for products that can be made out of agave fibers like bricks, single-use cups, plates, and even glassware. Other tequila brands are also finding creative ways to eliminate the waste of agave fibers. Cazadores uses them, among other ingredients, as fuel to power its distillation process. Jose Cuervo has upcycled agave fibers to manufacture some out-of-the-box products including guitars and surf

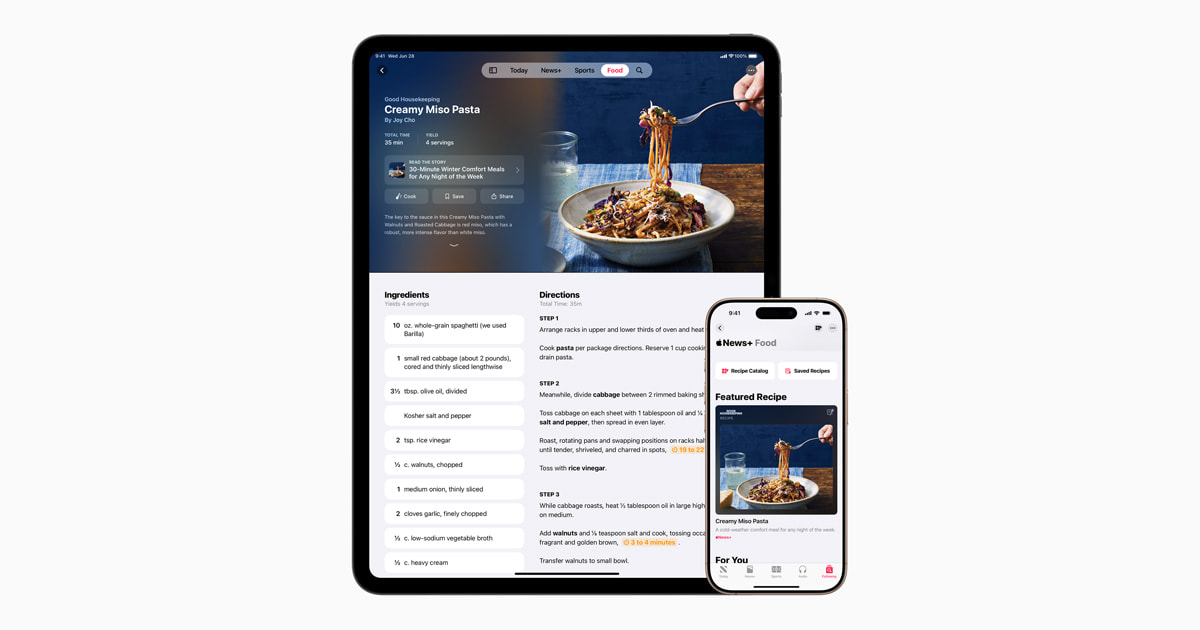

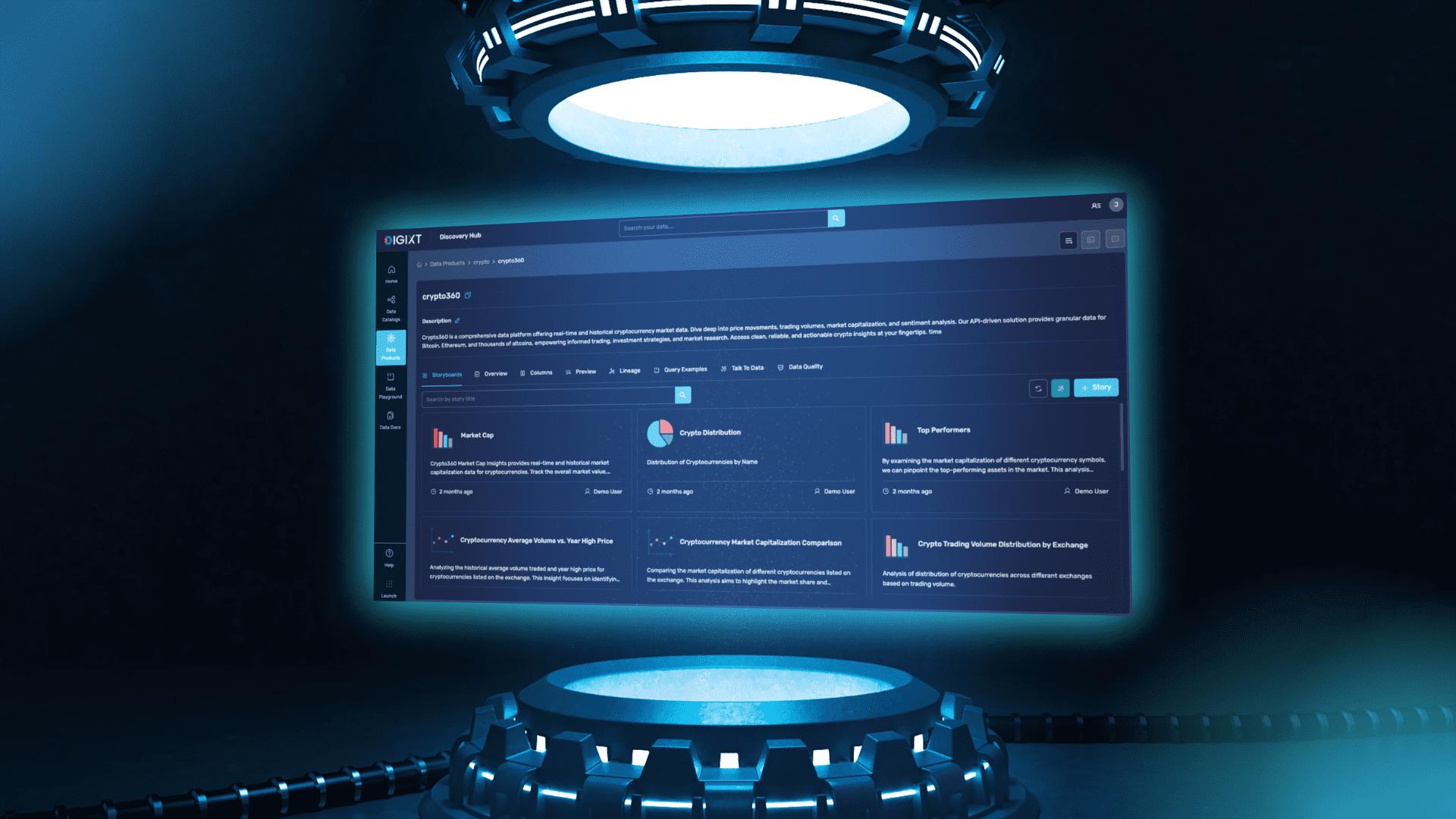

Design-minded home goods brand Simplehuman recently released a product that’s a little out of its wheelhouse—a limited-edition tequila with distillery Nosotros. It may be the company’s first foray into spirits, but the brand already knows how to work with the Weber blue agave that made the tequila.

The agave fibers on Simplehuman’s Soapwell sponge begin their life cycle by being pressed into Nosotros tequila at the company’s distillery in Tequila, Mexico. Nosotros then supplies its leftover agave fibers to Simplehuman. The $100 Nosotros x Simplehuman Blanco tequila is made out of that same agave, and was released to mark a year that Simplehuman has been spinning the fibers into sponges.

Simplehuman CEO Frank Yang says the company approached the tequila the same way it does any product—and notes that the agave-sourcing partnership shows off the “less is more” approach that guides both brands.

“We’re trying to create cool things that exist in the world that people would miss if we weren’t doing this,” Yang says.

High proof, high performance

The story of how tequila ingredients became a kitchen product isn’t too complicated. It starts with Yang’s fondness for tequila. While on vacation in Mexico in 2022, he joined a tequila-making class and learned how agave is used to make the spirit. “They were telling me how the fiber is really tough,” he says, noting that after the juice was extracted, “it seemed like they were throwing the [pulp] away.”

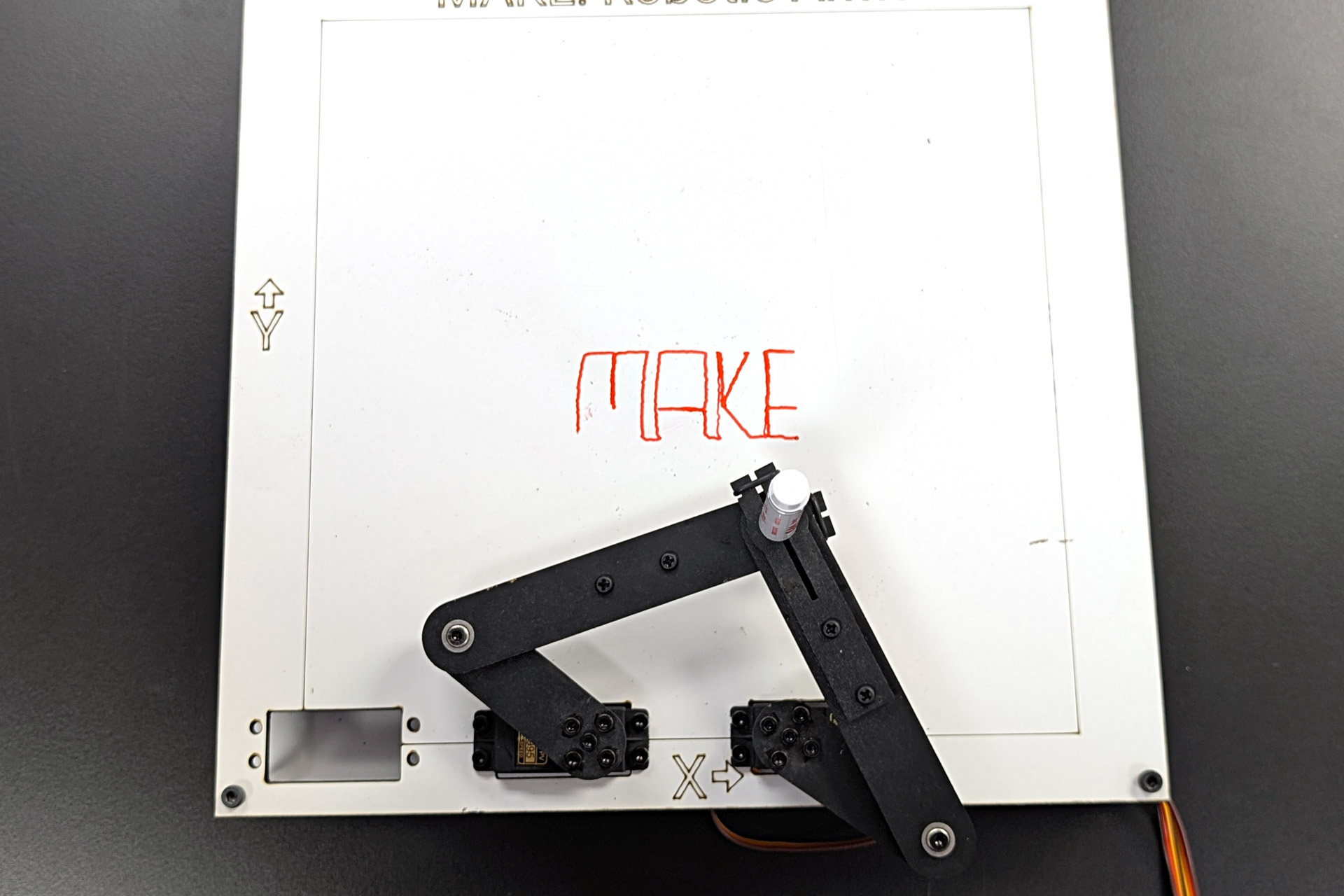

The Simplehuman R&D team was both skeptical and excited. It was a tricky process, working with jimadores (farmers who harvest agave plants in Mexico) to handpick specific fibers amid the gunky pulp. But after about eight months, they realized it was a solution that could help create a soft sponge that could also scrub without scratching pots and pans. “High performance is the most important,” he says.

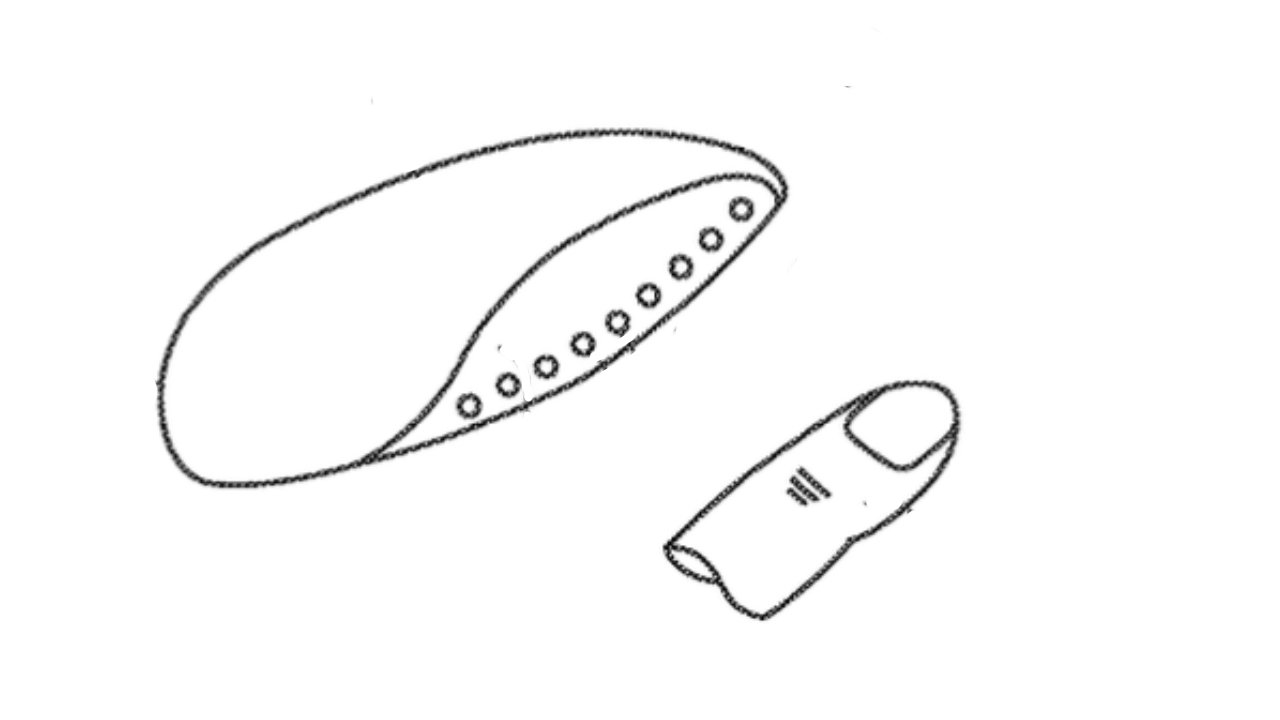

Besides the agave fibers, the sponge’s differentiator is a round reservoir—the sponge’s eponymous soap well. “[The soap] seeps down to the sponge so it doesn’t just wash away,” Yang says.

The circular well is positioned to match where soap comes out of a Simplehuman soap dispenser, and also has a hard outer ring that can offer a deeper scrub for stubborn residue.

A tequila influenced by terrain

Nosotros approaches tequila like wine—each spirit taking on unique characteristics based on the land where its agave grows. The Nosotros x Simplehuman bottle of additive-free Blanco tequila is not made differently than Nosotros’s other bottles of Blanco, but is a particular vintage.

Nosotros cofounder Carlos Soto describes this specific Simplehuman vintage as mineral-forward. “A lot of times with our Blanco, we’ve had the highlands carry a lot of it—more fruity notes and that cooked agave sweetness,” he says. He’s referring to the Mexican highlands of Arasco, Jalisco, where 50% of the agave for Nosotros tequila comes from. The other 50% comes from the city of Tequila, located in the lowlands of Jalisco, and comes across as more dominant in this vintage.

“Lowlands usually have a lot more shade. . . . They tend to have soil that is very rich,” Soto says. “They become a little bit more peppery, more earthy.”

The approach that Nosotros takes of utilizing these two agaves not only provides a more balanced taste across its line of additive-free products, but also reduces stress on the environment. “The farms that we work with are able to rotate crops a little bit more just because we’re only using 50% from each,” Soto says. “It really protects the soil, which keeps the quality of the agave.”

The amount of agave required to yield one bottle of tequila produces enough fibers to make more than 2,000 sponges.

Giving agave fibers a second life

Soto says he thinks of Nosotros as an agave company, and he is always searching for ways to utilize agave fibers. Even before the Simplehuman partnership, Nosotros used fibers to create the labels on all of its bottles, and often recycles the fibers as fertilizer. But the company still regularly has a surplus. “We struggle to allocate [the remaining fibers] sometimes,” Soto says. “We don’t want to just throw it in a landfill.”

Simplehuman is Nosotros’s first agave brand partner, and it sees more opportunity to work with other brands to give agave a second life. “There’s so much tequila being produced right now, Soto says. “There are more fibers than people who are taking it.” The company is in the early stages of creating a bigger market for products that can be made out of agave fibers like bricks, single-use cups, plates, and even glassware.

Other tequila brands are also finding creative ways to eliminate the waste of agave fibers. Cazadores uses them, among other ingredients, as fuel to power its distillation process. Jose Cuervo has upcycled agave fibers to manufacture some out-of-the-box products including guitars and surfboards.

Though the Simplehuman x Nosotros blanco tequila will only be available until the vintage is sold out, it’s a way to underscore how Simplehuman approaches its product development. Yang notes: “If it’s not functional, why is it there?”

![[The AI Show Episode 146]: Rise of “AI-First” Companies, AI Job Disruption, GPT-4o Update Gets Rolled Back, How Big Consulting Firms Use AI, and Meta AI App](https://www.marketingaiinstitute.com/hubfs/ep%20146%20cover.png)

![|ー ▶︎ [ Wouldn't it be easier if you could trace your data structure with lines? ] ー,ー,ー;](https://media2.dev.to/dynamic/image/width%3D1000,height%3D500,fit%3Dcover,gravity%3Dauto,format%3Dauto/https:%2F%2Fdev-to-uploads.s3.amazonaws.com%2Fuploads%2Farticles%2F2k02ska8tyhhnijercgq.png)

_Brian_Jackson_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

Stolen 884,000 Credit Card Details on 13 Million Clicks from Users Worldwide.webp?#)

![Apple Shares Official Teaser for 'Highest 2 Lowest' Starring Denzel Washington [Video]](https://www.iclarified.com/images/news/97221/97221/97221-640.jpg)

![Under-Display Face ID Coming to iPhone 18 Pro and Pro Max [Rumor]](https://www.iclarified.com/images/news/97215/97215/97215-640.jpg)