AI in Warehouses: Because Human Errors Are Too Expensive

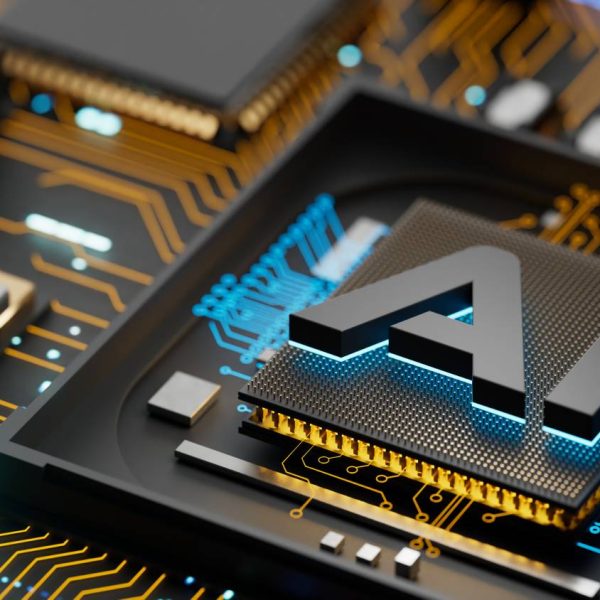

Warehouses are the backbone of logistics, ensuring that products move smoothly from manufacturers to customers. But as demand grows, traditional warehouse management systems are struggling to keep up. Delayed shipments, inventory mismatches, and inefficient workflows are costing businesses time and money. This is where AI Consulting Services come into play, helping businesses implement AI-driven solutions to optimize warehouse management. By leveraging AI, companies can enhance accuracy, efficiency, and scalability without completely overhauling their existing systems. AI-powered warehouse management is no longer a luxury reserved for large corporations. Businesses of all sizes can now take advantage of these advancements to stay ahead of the competition. Let’s explore how AI is transforming warehouse management and why integrating AI-driven solutions can future-proof logistics operations. The Challenges of Traditional Warehouse Management Legacy warehouse management systems were designed for an era when logistics was simpler and slower. Today, they are struggling to keep pace with increasing demand. Here are some common challenges businesses face with outdated warehouse management systems: Lack of real-time insights leads to inventory discrepancies and delays Heavy reliance on manual processes increases errors and inefficiencies Slow order fulfillment impacts customer satisfaction and revenue Scalability becomes a challenge, creating bottlenecks as businesses grow These inefficiencies not only increase costs but also limit a company’s ability to meet market demand. AI provides a solution that enhances existing systems without requiring a complete overhaul. How AI is Transforming Warehouse Operations AI-driven warehouse management brings automation, real-time data processing, and predictive analytics into logistics operations. Here are some of the key ways AI is improving warehouse efficiency. Real-Time Inventory Tracking and Accuracy One of the biggest challenges in warehouse management is keeping inventory data accurate. AI-powered systems use automated scanning, IoT sensors, and machine learning to provide real-time visibility into stock levels. This ensures that businesses avoid overstocking, stockouts, and misplaced inventory, leading to improved operational efficiency. AI-Driven Demand Forecasting Traditional demand forecasting relies on past sales data, but AI takes forecasting to the next level by analyzing market trends, seasonal fluctuations, and customer behavior patterns. This allows businesses to predict demand with greater accuracy, ensuring they have the right inventory at the right time. With AI-driven forecasting, companies can reduce excess inventory, lower storage costs, and avoid lost sales due to stock shortages. Automated Order Processing and Fulfillment Picking, sorting, and packing are among the most time-consuming tasks in warehouse operations. AI-driven automation streamlines these processes by using robotics, machine learning algorithms, and real-time data analysis. Automated fulfillment reduces errors, speeds up order processing, and improves customer satisfaction. It also frees up human workers to focus on more strategic tasks rather than repetitive manual labor. Warehouse Layout Optimization A poorly designed warehouse layout can significantly impact efficiency. AI analyzes movement patterns within a warehouse and optimizes storage arrangements to minimize retrieval time and maximize space utilization. By placing high-demand items in easily accessible locations, businesses can reduce time spent retrieving products and improve overall workflow. Predictive Maintenance for Equipment Warehouse operations rely heavily on machinery such as conveyor belts, forklifts, and automated sorting systems. Unexpected breakdowns can cause major disruptions. AI-powered predictive maintenance analyzes performance data to detect potential issues before they result in costly downtime. This allows businesses to schedule maintenance proactively, reducing repair costs and ensuring smooth operations. Why AI is the Future of Warehouse Management The adoption of AI in warehouse management is not just a trend; it is a necessity for businesses that want to remain competitive. Companies that invest in AI-driven warehouse solutions benefit from: Increased scalability as AI-powered systems adapt to growing demand Cost savings through automation and reduced operational inefficiencies Improved customer experience with faster, more accurate order fulfillment At AQe Digital, we specialize in integrating AI-driven solutions into warehouse management, helping businesses optimize operations, reduce costs, and improve efficiency. To dive deeper into AI in warehouse management, explore our detailed blog post now.

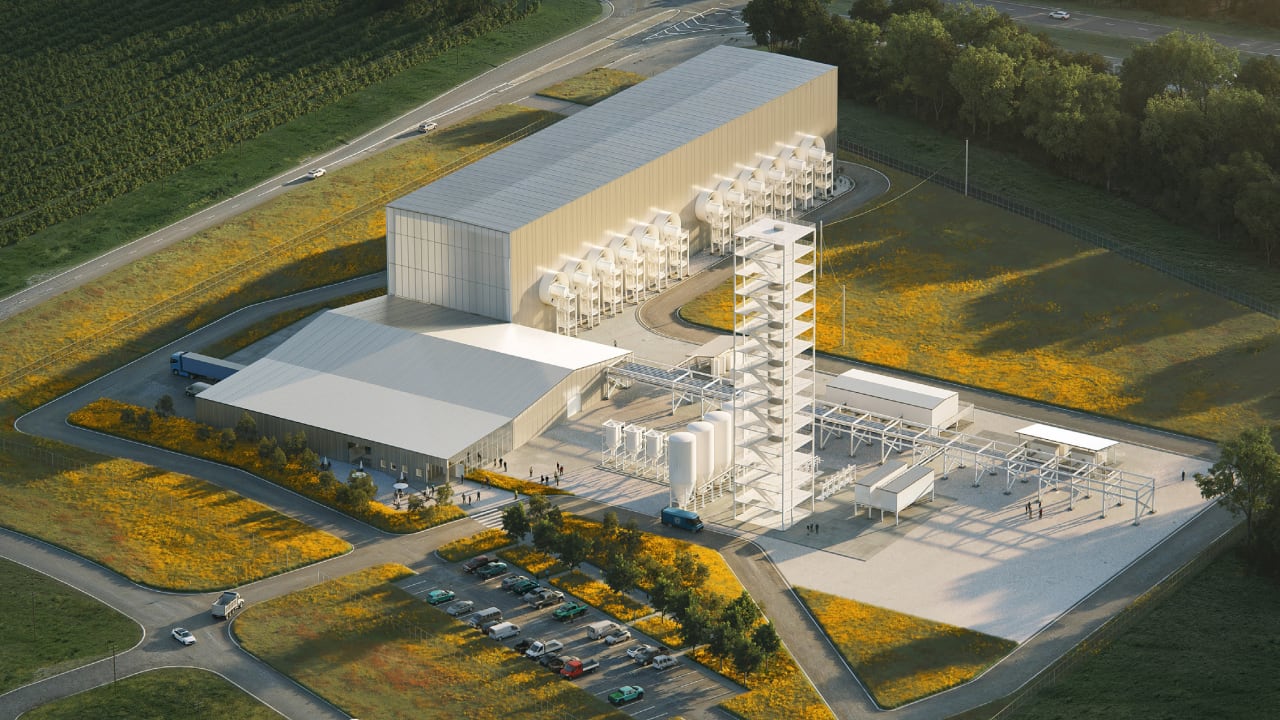

Warehouses are the backbone of logistics, ensuring that products move smoothly from manufacturers to customers. But as demand grows, traditional warehouse management systems are struggling to keep up. Delayed shipments, inventory mismatches, and inefficient workflows are costing businesses time and money.

This is where AI Consulting Services come into play, helping businesses implement AI-driven solutions to optimize warehouse management. By leveraging AI, companies can enhance accuracy, efficiency, and scalability without completely overhauling their existing systems.

AI-powered warehouse management is no longer a luxury reserved for large corporations. Businesses of all sizes can now take advantage of these advancements to stay ahead of the competition.

Let’s explore how AI is transforming warehouse management and why integrating AI-driven solutions can future-proof logistics operations.

The Challenges of Traditional Warehouse Management

Legacy warehouse management systems were designed for an era when logistics was simpler and slower. Today, they are struggling to keep pace with increasing demand.

Here are some common challenges businesses face with outdated warehouse management systems:

Lack of real-time insights leads to inventory discrepancies and delays

Heavy reliance on manual processes increases errors and inefficiencies

Slow order fulfillment impacts customer satisfaction and revenue

Scalability becomes a challenge, creating bottlenecks as businesses grow

These inefficiencies not only increase costs but also limit a company’s ability to meet market demand. AI provides a solution that enhances existing systems without requiring a complete overhaul.

How AI is Transforming Warehouse Operations

AI-driven warehouse management brings automation, real-time data processing, and predictive analytics into logistics operations. Here are some of the key ways AI is improving warehouse efficiency.

Real-Time Inventory Tracking and Accuracy

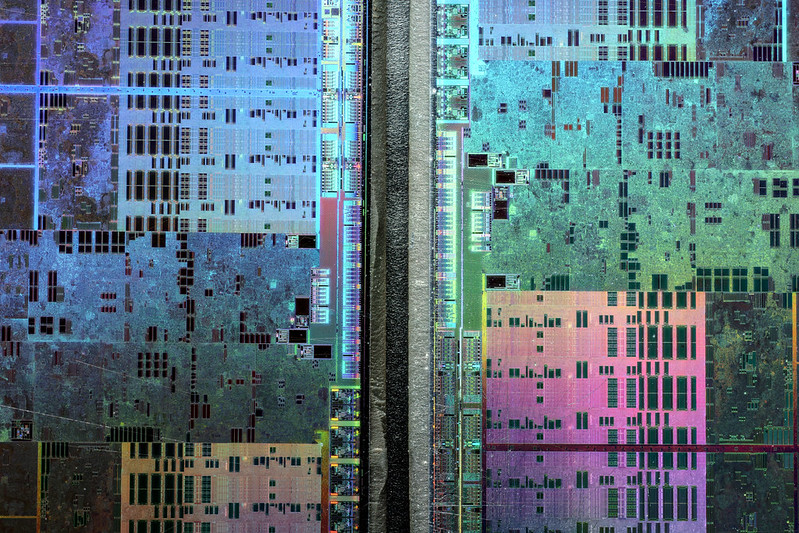

One of the biggest challenges in warehouse management is keeping inventory data accurate. AI-powered systems use automated scanning, IoT sensors, and machine learning to provide real-time visibility into stock levels.

This ensures that businesses avoid overstocking, stockouts, and misplaced inventory, leading to improved operational efficiency.

AI-Driven Demand Forecasting

Traditional demand forecasting relies on past sales data, but AI takes forecasting to the next level by analyzing market trends, seasonal fluctuations, and customer behavior patterns. This allows businesses to predict demand with greater accuracy, ensuring they have the right inventory at the right time.

With AI-driven forecasting, companies can reduce excess inventory, lower storage costs, and avoid lost sales due to stock shortages.

Automated Order Processing and Fulfillment

Picking, sorting, and packing are among the most time-consuming tasks in warehouse operations. AI-driven automation streamlines these processes by using robotics, machine learning algorithms, and real-time data analysis.

Automated fulfillment reduces errors, speeds up order processing, and improves customer satisfaction. It also frees up human workers to focus on more strategic tasks rather than repetitive manual labor.

Warehouse Layout Optimization

A poorly designed warehouse layout can significantly impact efficiency. AI analyzes movement patterns within a warehouse and optimizes storage arrangements to minimize retrieval time and maximize space utilization.

By placing high-demand items in easily accessible locations, businesses can reduce time spent retrieving products and improve overall workflow.

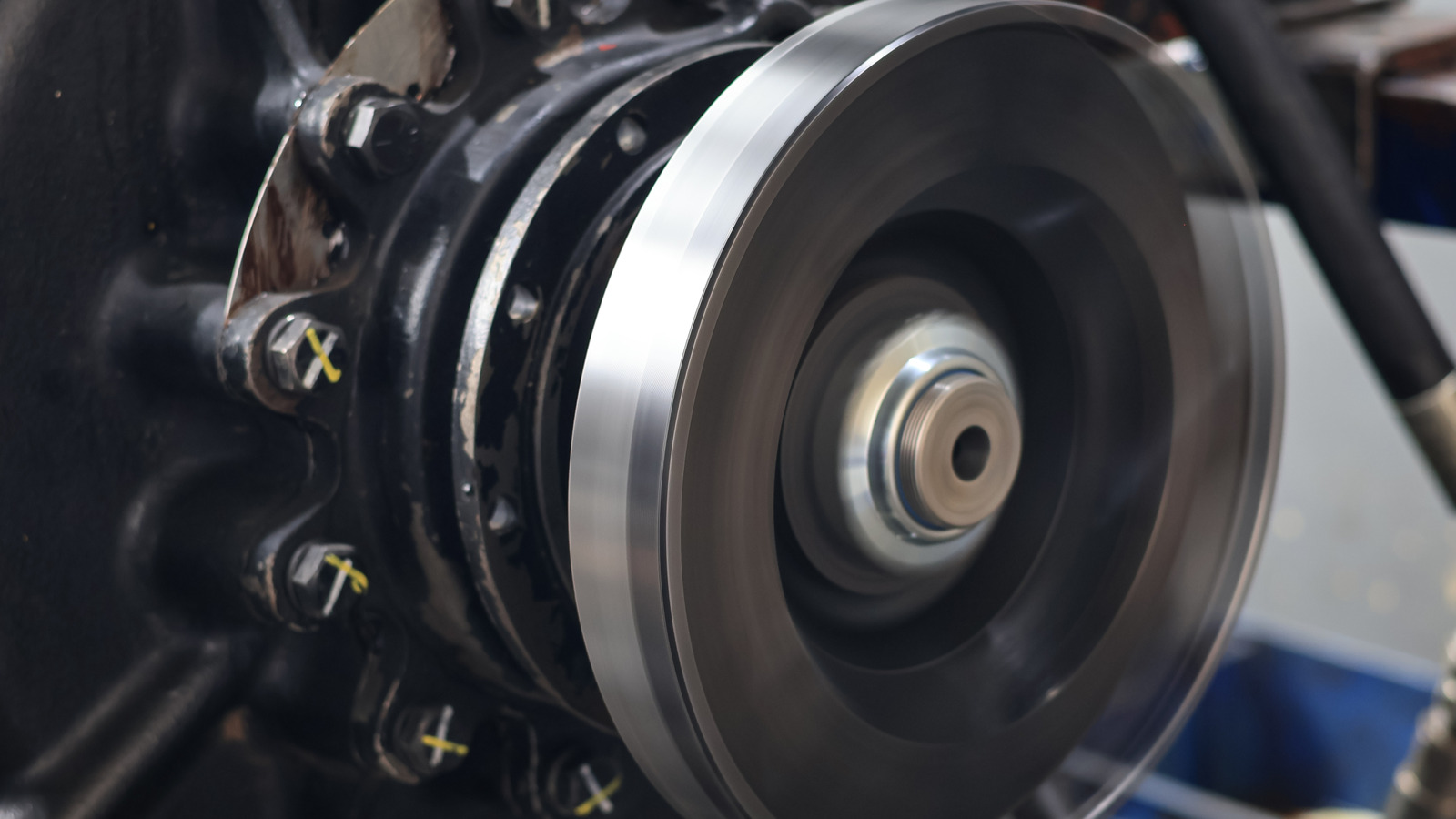

Predictive Maintenance for Equipment

Warehouse operations rely heavily on machinery such as conveyor belts, forklifts, and automated sorting systems. Unexpected breakdowns can cause major disruptions. AI-powered predictive maintenance analyzes performance data to detect potential issues before they result in costly downtime.

This allows businesses to schedule maintenance proactively, reducing repair costs and ensuring smooth operations.

Why AI is the Future of Warehouse Management

The adoption of AI in warehouse management is not just a trend; it is a necessity for businesses that want to remain competitive. Companies that invest in AI-driven warehouse solutions benefit from:

Increased scalability as AI-powered systems adapt to growing demand

Cost savings through automation and reduced operational inefficiencies

Improved customer experience with faster, more accurate order fulfillment

At AQe Digital, we specialize in integrating AI-driven solutions into warehouse management, helping businesses optimize operations, reduce costs, and improve efficiency.

To dive deeper into AI in warehouse management, explore our detailed blog post now.

![[The AI Show Episode 144]: ChatGPT’s New Memory, Shopify CEO’s Leaked “AI First” Memo, Google Cloud Next Releases, o3 and o4-mini Coming Soon & Llama 4’s Rocky Launch](https://www.marketingaiinstitute.com/hubfs/ep%20144%20cover.png)

![GrandChase tier list of the best characters available [April 2025]](https://media.pocketgamer.com/artwork/na-33057-1637756796/grandchase-ios-android-3rd-anniversary.jpg?#)

![Apple M4 13-inch iPad Pro On Sale for $200 Off [Deal]](https://www.iclarified.com/images/news/97056/97056/97056-640.jpg)

![Apple Shares New 'Mac Does That' Ads for MacBook Pro [Video]](https://www.iclarified.com/images/news/97055/97055/97055-640.jpg)