Forklift Scales and PCB Integration

** Introduction ** Forklift scales are an essential component in warehouses, distribution centers, and manufacturing facilities, helping businesses weigh large and heavy items during transportation. These scales, often integrated directly into forklifts, provide real-time weight measurements, improving operational efficiency and reducing the risk of overloading. The Printed Circuit Board (PCB) plays a vital role in these systems, ensuring accurate data processing, sensor integration, and seamless communication with connected systems. In this article, we explore the significance of PCBs in forklift scales and how companies like Highleap Electronic provide innovative solutions that enhance the performance and reliability of these scales. **The Role of PCBs in Forklift Scales ** Forklift scales are designed to be durable, as they operate in tough industrial environments. They must withstand heavy mechanical stress, vibrations, and environmental factors such as temperature changes. The PCB is central to the functionality of forklift scales, as it processes data from load cells, compensates for environmental drift, and ensures accurate weight readings. The PCB communicates the processed weight data to the forklift's display or integrated system, allowing operators to see the weight of the load in real-time. The integration of PCBs with other systems in a warehouse, such as Warehouse Management Systems (WMS), is crucial for streamlining operations and improving inventory tracking. **Key Features of PCBs in Forklift Scales ** Signal Conditioning: The PCB ensures that signals from load cells are accurately processed, filtering out noise and compensating for temperature variations. Wireless Connectivity: Many forklift scales use PCBs that enable wireless communication, such as Bluetooth or Wi-Fi, allowing the system to sync data with centralized databases or other warehouse systems. Environmental Resistance: PCBs in forklift scales need to be resistant to harsh conditions, including moisture, dust, and mechanical impact. High-quality materials and protective coatings ensure that the PCB remains operational in challenging environments. The Importance of Reliable PCBs for Forklift Scales The performance of forklift scales directly impacts the efficiency of inventory management and logistics. Inaccurate weight readings could lead to costly mistakes, such as overloading vehicles or improper stock management. To maintain precision, forklift scales rely on durable and high-performing PCBs that can withstand demanding industrial conditions. By integrating advanced features like thermal compensation, signal amplification, and real-time data processing, PCBs play a critical role in ensuring the accuracy of forklift scales. Manufacturers looking to enhance their forklift scales can rely on robust PCBs to improve the system’s reliability and performance. Conclusion In forklift scales, PCBs are the backbone of reliable, accurate, and efficient weighing systems. By ensuring proper signal processing, compensating for environmental factors, and offering wireless connectivity, PCBs allow forklift scales to operate smoothly in demanding environments. Highleap Electronic, with its expertise in PCB manufacturing, provides advanced solutions for forklift scale manufacturers, ensuring the highest standards of accuracy and durability. For more information on Highleap Electronic and their PCB solutions, visit https://hilelectronic.com/.

**

Introduction

**

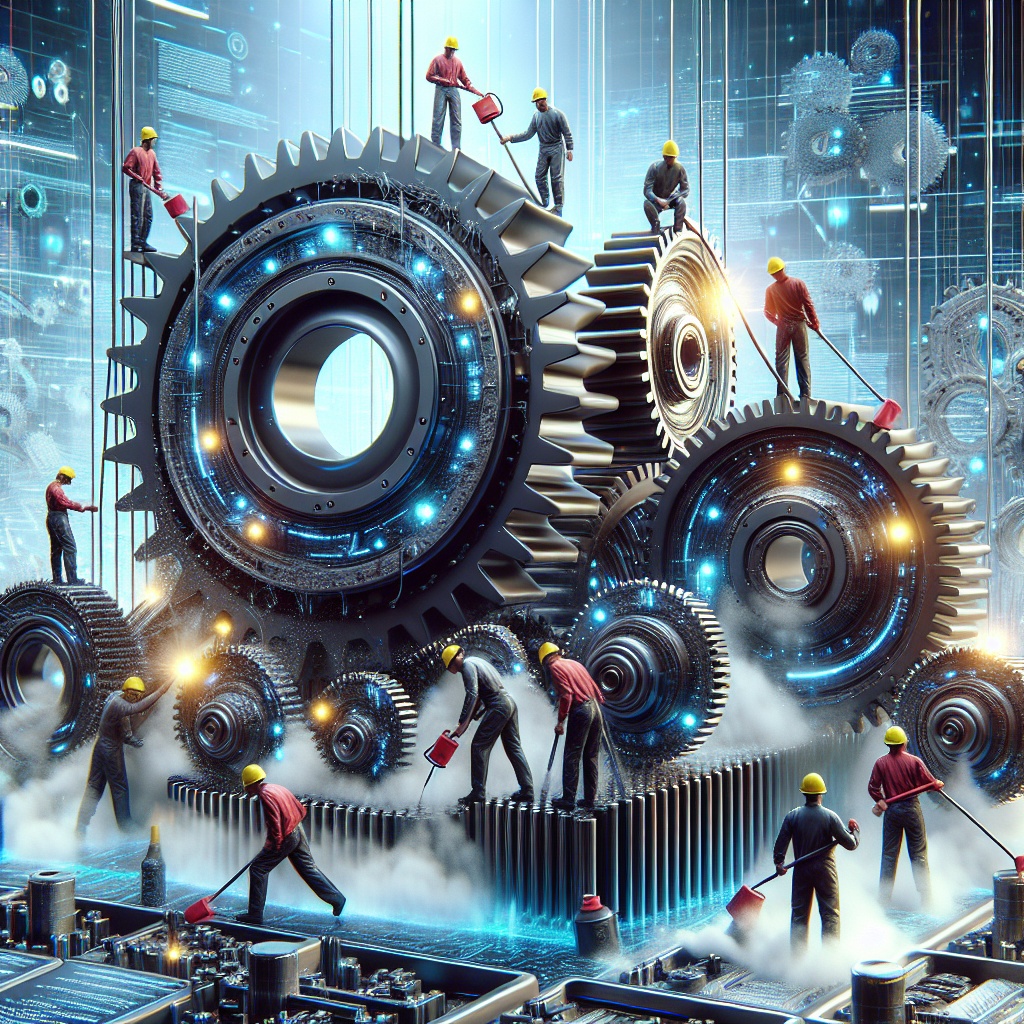

Forklift scales are an essential component in warehouses, distribution centers, and manufacturing facilities, helping businesses weigh large and heavy items during transportation. These scales, often integrated directly into forklifts, provide real-time weight measurements, improving operational efficiency and reducing the risk of overloading. The Printed Circuit Board (PCB) plays a vital role in these systems, ensuring accurate data processing, sensor integration, and seamless communication with connected systems.

In this article, we explore the significance of PCBs in forklift scales and how companies like Highleap Electronic provide innovative solutions that enhance the performance and reliability of these scales.

**The Role of PCBs in Forklift Scales

**

Forklift scales are designed to be durable, as they operate in tough industrial environments. They must withstand heavy mechanical stress, vibrations, and environmental factors such as temperature changes. The PCB is central to the functionality of forklift scales, as it processes data from load cells, compensates for environmental drift, and ensures accurate weight readings.

The PCB communicates the processed weight data to the forklift's display or integrated system, allowing operators to see the weight of the load in real-time. The integration of PCBs with other systems in a warehouse, such as Warehouse Management Systems (WMS), is crucial for streamlining operations and improving inventory tracking.

**Key Features of PCBs in Forklift Scales

**

Signal Conditioning: The PCB ensures that signals from load cells are accurately processed, filtering out noise and compensating for temperature variations.

Wireless Connectivity: Many forklift scales use PCBs that enable wireless communication, such as Bluetooth or Wi-Fi, allowing the system to sync data with centralized databases or other warehouse systems.

Environmental Resistance: PCBs in forklift scales need to be resistant to harsh conditions, including moisture, dust, and mechanical impact. High-quality materials and protective coatings ensure that the PCB remains operational in challenging environments.

The Importance of Reliable PCBs for Forklift Scales

The performance of forklift scales directly impacts the efficiency of inventory management and logistics. Inaccurate weight readings could lead to costly mistakes, such as overloading vehicles or improper stock management. To maintain precision, forklift scales rely on durable and high-performing PCBs that can withstand demanding industrial conditions.

By integrating advanced features like thermal compensation, signal amplification, and real-time data processing, PCBs play a critical role in ensuring the accuracy of forklift scales. Manufacturers looking to enhance their forklift scales can rely on robust PCBs to improve the system’s reliability and performance.

Conclusion

In forklift scales, PCBs are the backbone of reliable, accurate, and efficient weighing systems. By ensuring proper signal processing, compensating for environmental factors, and offering wireless connectivity, PCBs allow forklift scales to operate smoothly in demanding environments. Highleap Electronic, with its expertise in PCB manufacturing, provides advanced solutions for forklift scale manufacturers, ensuring the highest standards of accuracy and durability.

For more information on Highleap Electronic and their PCB solutions, visit https://hilelectronic.com/.

![[The AI Show Episode 142]: ChatGPT’s New Image Generator, Studio Ghibli Craze and Backlash, Gemini 2.5, OpenAI Academy, 4o Updates, Vibe Marketing & xAI Acquires X](https://www.marketingaiinstitute.com/hubfs/ep%20142%20cover.png)

![From drop-out to software architect with Jason Lengstorf [Podcast #167]](https://cdn.hashnode.com/res/hashnode/image/upload/v1743796461357/f3d19cd7-e6f5-4d7c-8bfc-eb974bc8da68.png?#)

![Switch 2 Pre-Order Rules Are Some BS: Here's How They Work [Update]](https://i.kinja-img.com/image/upload/c_fill,h_675,pg_1,q_80,w_1200/485ec87fd3cea832387b2699e4cbd2a1.jpg)

.png?#)

(1).jpg?width=1920&height=1920&fit=bounds&quality=80&format=jpg&auto=webp#)

-Mario-Kart-World-Hands-On-Preview-Is-It-Good-00-08-36.jpg?width=1920&height=1920&fit=bounds&quality=80&format=jpg&auto=webp#)

_NicoElNino_Alamy.png?#)

_Igor_Mojzes_Alamy.jpg?#)

.webp?#)

.webp?#)

![Blackmagic Design Unveils DaVinci Resolve 20 With Over 100 New Features and AI Tools [Video]](https://www.iclarified.com/images/news/96951/96951/96951-640.jpg)

![Apple Considers Delaying Smart Home Hub Until 2026 [Gurman]](https://www.iclarified.com/images/news/96946/96946/96946-640.jpg)