Chocolate-free brownies and coffee-less cold brew: AI might help food brands weather the tariffs

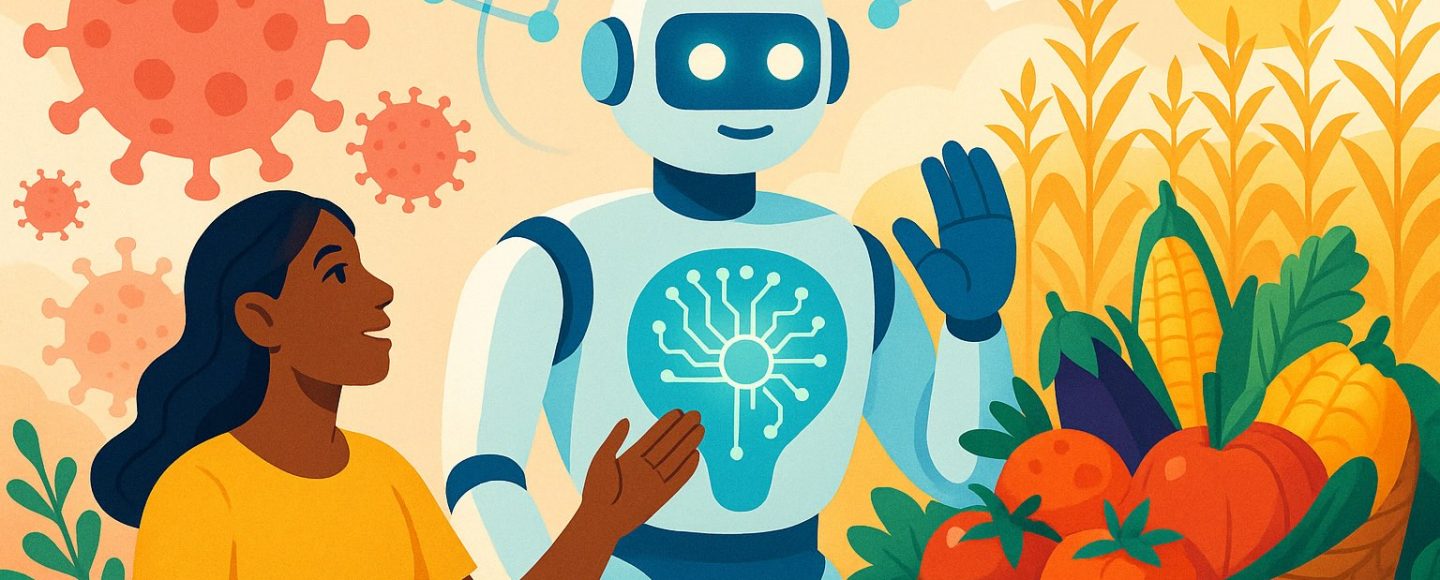

Brownies with no chocolate, and cold brew with no coffee beans: With the return of U.S. tariffs still uncertain, reformulated snacks might soon be on the horizon. Whether it’s a global pandemic, looming trade wars, or actual wars, supply chain disruptions and continuity struggles are becoming increasingly common. In response, consumer packaged goods (CPG) companies are turning to Chilean food-tech startup NotCo to help reformulate fan favorites and build resilience to supply chain disruptions. Based in Santiago, Chile, with a U.S.-based hub in San Francisco, NotCo adopted AI early, launching a proprietary AI-powered product development platform called Giuseppe a decade ago. The engine was trained using curated data on everything from industrial food production processes and the molecular composition of over 8,000 ingredients to product reviews and social media insights. The result is an end-to-end service that guides product development from concept generation to exact formulation. NotCo first used its product development platform to create its own line of CPG offerings, including plant-based alternatives like NotMayo and NotMilk. In 2022, the company reached a $1.5 billion valuation, driven by the strength of its AI services. “We are a CPG company as well, so all of our algorithms were created for exactly the same problems that these big companies have,” NotCo CEO Matias Muchnick says. “The thing is, we are 10 years ahead of them.” [Photo: NotCo] Now operating as a B2B platform, NotCo has partnered with major brands like Kraft and Shake Shack to develop plant-based versions of existing products. For Kraft Heinz JV, Giuseppe helped create cheddar cheese and mac and cheese alternatives that preserved the original flavor while cutting costs. For Shake Shack, NotCo formulated a plant-based version of the chain’s custard ice cream, maintaining both taste and texture. For both of these projects, the traditional development timeline would have taken 12 to 18 months, but with the AI tool, development time was cut to less than six months. A collaboration between humans and technology “AI is not to replace the product developer, it is to accelerate their learnings and to augment the product developer,” says NotCo Vice President of R&D Alisia Heath. R&D teams input specific constraints—such as budget, production requirements, restricted ingredients, desired taste, and texture—into the platform, which helps avoid trial-and-error paths unlikely to meet the product’s needs. “AI allows you to minimize, to put a lot of inputs, a lot of restrictions at the very beginning of a formulation process, so as you don’t get any surprises,” Muchnick tells Fast Company. Giuseppe then generates five formulations for developers to test in a sensory analysis. Feedback from those tests is used to fine-tune the ingredient ratios and produce another set of five improved formulations. “You change one thing, you change every other thing. So it’s not just by replacing one thing, you’re going to get it right. Everything else will change,” Muchnick says. “Our technology allows you to understand how the rest of the formulation will change when you change one variable, and that allows you to actually get way more efficient and avoid going into a trial.” Beyond efficiency, Giuseppe’s greatest strength may be its ability to understand flavor at the molecular level, allowing for unconventional ingredient combinations that replicate traditional flavors. For example, the dairy flavor in NotMilk is recreated using a blend of cabbage and pineapple. By removing human bias about how something should taste, the AI explores how it could taste. “You’re able to look at the molecular structure of the target ingredient or the target product, and look at ingredients that might have a similar composition as a recommendation to try and use, and an exploration space for the tool to generate experiments,” Head says. A relief for external pressures NotCo’s rapid and cost-effective R&D capabilities are now being applied to address broader challenges such as supply constraints and shifting regulations. The company is working on confidential reformulation projects addressing “supply continuity issues,” and is in “initial discussions with clients regarding tariffs,” according to Head. NotCo is currently collaborating with seven of the world’s twenty largest CPG brands, though it declined to name them. But looming tariffs are not the only constraint faced by CPG companies, as policies regarding sustainability and food safety continue to evolve. “There’s a lot of external pressures going on, whether it is tariffs, whether it is state sustainability, whether it’s profitability, there’s a lot of pressures out there,” Muchnick says. “What we can do differently is go outside that traditional landscape and solve those challenges.”

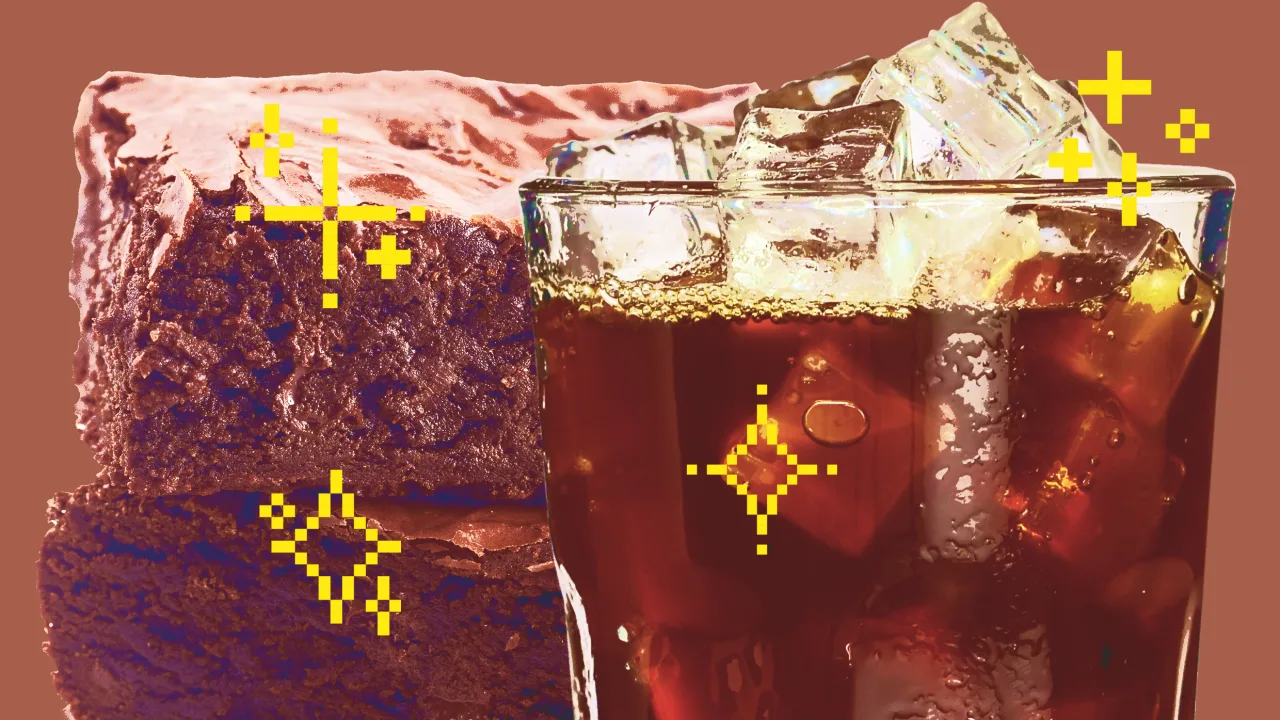

Brownies with no chocolate, and cold brew with no coffee beans: With the return of U.S. tariffs still uncertain, reformulated snacks might soon be on the horizon.

Whether it’s a global pandemic, looming trade wars, or actual wars, supply chain disruptions and continuity struggles are becoming increasingly common. In response, consumer packaged goods (CPG) companies are turning to Chilean food-tech startup NotCo to help reformulate fan favorites and build resilience to supply chain disruptions.

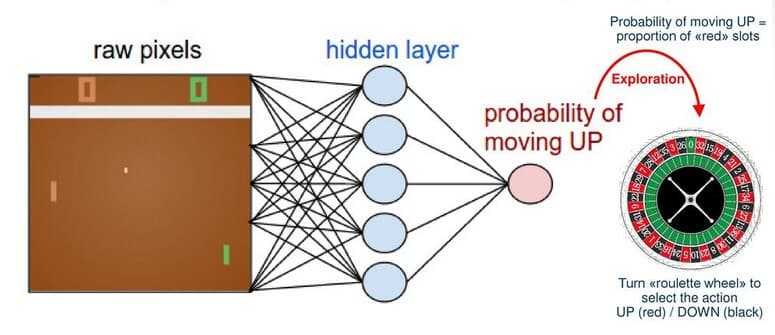

Based in Santiago, Chile, with a U.S.-based hub in San Francisco, NotCo adopted AI early, launching a proprietary AI-powered product development platform called Giuseppe a decade ago. The engine was trained using curated data on everything from industrial food production processes and the molecular composition of over 8,000 ingredients to product reviews and social media insights. The result is an end-to-end service that guides product development from concept generation to exact formulation.

NotCo first used its product development platform to create its own line of CPG offerings, including plant-based alternatives like NotMayo and NotMilk. In 2022, the company reached a $1.5 billion valuation, driven by the strength of its AI services.

“We are a CPG company as well, so all of our algorithms were created for exactly the same problems that these big companies have,” NotCo CEO Matias Muchnick says. “The thing is, we are 10 years ahead of them.”

Now operating as a B2B platform, NotCo has partnered with major brands like Kraft and Shake Shack to develop plant-based versions of existing products. For Kraft Heinz JV, Giuseppe helped create cheddar cheese and mac and cheese alternatives that preserved the original flavor while cutting costs. For Shake Shack, NotCo formulated a plant-based version of the chain’s custard ice cream, maintaining both taste and texture.

For both of these projects, the traditional development timeline would have taken 12 to 18 months, but with the AI tool, development time was cut to less than six months.

A collaboration between humans and technology

“AI is not to replace the product developer, it is to accelerate their learnings and to augment the product developer,” says NotCo Vice President of R&D Alisia Heath.

R&D teams input specific constraints—such as budget, production requirements, restricted ingredients, desired taste, and texture—into the platform, which helps avoid trial-and-error paths unlikely to meet the product’s needs.

“AI allows you to minimize, to put a lot of inputs, a lot of restrictions at the very beginning of a formulation process, so as you don’t get any surprises,” Muchnick tells Fast Company.

Giuseppe then generates five formulations for developers to test in a sensory analysis. Feedback from those tests is used to fine-tune the ingredient ratios and produce another set of five improved formulations.

“You change one thing, you change every other thing. So it’s not just by replacing one thing, you’re going to get it right. Everything else will change,” Muchnick says. “Our technology allows you to understand how the rest of the formulation will change when you change one variable, and that allows you to actually get way more efficient and avoid going into a trial.”

Beyond efficiency, Giuseppe’s greatest strength may be its ability to understand flavor at the molecular level, allowing for unconventional ingredient combinations that replicate traditional flavors. For example, the dairy flavor in NotMilk is recreated using a blend of cabbage and pineapple. By removing human bias about how something should taste, the AI explores how it could taste.

“You’re able to look at the molecular structure of the target ingredient or the target product, and look at ingredients that might have a similar composition as a recommendation to try and use, and an exploration space for the tool to generate experiments,” Head says.

A relief for external pressures

NotCo’s rapid and cost-effective R&D capabilities are now being applied to address broader challenges such as supply constraints and shifting regulations.

The company is working on confidential reformulation projects addressing “supply continuity issues,” and is in “initial discussions with clients regarding tariffs,” according to Head. NotCo is currently collaborating with seven of the world’s twenty largest CPG brands, though it declined to name them.

But looming tariffs are not the only constraint faced by CPG companies, as policies regarding sustainability and food safety continue to evolve.

“There’s a lot of external pressures going on, whether it is tariffs, whether it is state sustainability, whether it’s profitability, there’s a lot of pressures out there,” Muchnick says. “What we can do differently is go outside that traditional landscape and solve those challenges.”

![[The AI Show Episode 145]: OpenAI Releases o3 and o4-mini, AI Is Causing “Quiet Layoffs,” Executive Order on Youth AI Education & GPT-4o’s Controversial Update](https://www.marketingaiinstitute.com/hubfs/ep%20145%20cover.png)

![From Art School Drop-out to Microsoft Engineer with Shashi Lo [Podcast #170]](https://cdn.hashnode.com/res/hashnode/image/upload/v1746203291209/439bf16b-c820-4fe8-b69e-94d80533b2df.png?#)

(1).jpg?#)

![Apple Developing AI 'Vibe-Coding' Assistant for Xcode With Anthropic [Report]](https://www.iclarified.com/images/news/97200/97200/97200-640.jpg)

![Apple's New Ads Spotlight Apple Watch for Kids [Video]](https://www.iclarified.com/images/news/97197/97197/97197-640.jpg)

![[Weekly funding roundup April 26-May 2] VC inflow continues to remain downcast](https://images.yourstory.com/cs/2/220356402d6d11e9aa979329348d4c3e/WeeklyFundingRoundupNewLogo1-1739546168054.jpg)