Revolutionizing High-Power and Low-TCR Thick Film Resistors with Carbon Nanotube Technology

The demand for high-performance resistors is constantly growing, driven by advancements in power electronics, automotive technology, industrial automation, and more. Traditional thick film resistor technologies are often challenged to meet the increasingly stringent requirements for both high power handling and excellent temperature stability. Introducing a revolutionary approach: Carbon Nanotube (CNT) Thick Film Resistors, offering a compelling alternative to conventional solutions. The Promise of Carbon Nanotubes in Thick Film Resistors Carbon nanotubes possess exceptional properties, including high electrical conductivity, remarkable mechanical strength, and excellent thermal stability. These characteristics make them ideal candidates for creating a new generation of thick film resistors that outperform existing technologies. Our CNT-based thick film resistors leverage these inherent advantages to deliver unmatched performance in demanding applications. Key Advantages of Our Carbon Nanotube Thick Film Resistors: High-Power Handling (High-Power Thick Film Resistor): CNTs excel at dissipating heat. Our resistors are engineered to withstand significantly higher power loads compared to traditional thick film resistors of comparable size. This allows for miniaturization of power circuits without sacrificing performance or reliability. Specifically, the unique network structure formed by CNTs within the thick film matrix enables efficient heat transfer, preventing localized hot spots and ensuring stable operation at elevated power levels. We've achieved demonstrably superior power handling capabilities in rigorous testing, exceeding industry standards. Ultra-Low Temperature Coefficient of Resistance (Low-TCR Thick Film Resistor): Temperature variations can significantly affect the resistance value of conventional resistors, leading to inaccuracies and performance degradation. Our CNT thick film resistors exhibit an exceptionally low Temperature Coefficient of Resistance (TCR). This means that the resistance value remains remarkably stable across a wide temperature range, ensuring consistent and reliable performance in diverse operating environments. This stability is crucial for precision applications in instrumentation, measurement, and control systems. Our innovative formulation and processing techniques minimize the inherent TCR of the carbon nanotubes themselves, resulting in a truly exceptional low-TCR product. Tailored Resistivity and Performance: Using a carefully formulated paste with a resistivity of 5 Ω.cm, we can precisely control the electrical properties of our CNT thick film resistors. This allows us to tailor the resistance value to meet specific customer requirements. The 5 Ω.cm resistivity provides an optimal balance between sheet resistance and film thickness, leading to excellent performance characteristics. We offer a range of resistance values and power ratings to perfectly match your application needs. Enhanced Stability and Reliability: The robust nature of carbon nanotubes contributes to the exceptional long-term stability and reliability of our thick film resistors. They are less susceptible to degradation from environmental factors such as humidity, temperature cycling, and chemical exposure. Compact Size and Miniaturization: The superior power handling capabilities of our CNT thick film resistors allow for the use of smaller components, contributing to overall circuit miniaturization. This is particularly beneficial in applications where space is limited, such as portable devices, automotive electronics, and aerospace systems. Applications: Our carbon nanotube thick film resistors are ideal for a wide range of applications, including: Power Supplies Motor Control Automotive Electronics (e.g., Battery Management Systems) LED Lighting Industrial Automation Instrumentation Measurement and Control Systems Renewable Energy Systems (e.g., Solar Inverters) The Future of Resistor Technology Carbon nanotube thick film resistors represent a significant advancement in resistor technology, offering a compelling combination of high power handling, low TCR, and exceptional stability. With our expertise in CNT materials and thick film processing, we are committed to delivering innovative solutions that meet the evolving needs of our customers. Contact us today to learn more about our carbon nanotube thick film resistors and how they can improve the performance of your products. Let us help you revolutionise your own designs with the high-power, low-TCR solution that only CNT technology can provide.

The demand for high-performance resistors is constantly growing, driven by advancements in power electronics, automotive technology, industrial automation, and more. Traditional thick film resistor technologies are often challenged to meet the increasingly stringent requirements for both high power handling and excellent temperature stability. Introducing a revolutionary approach: Carbon Nanotube (CNT) Thick Film Resistors, offering a compelling alternative to conventional solutions.

The Promise of Carbon Nanotubes in Thick Film Resistors

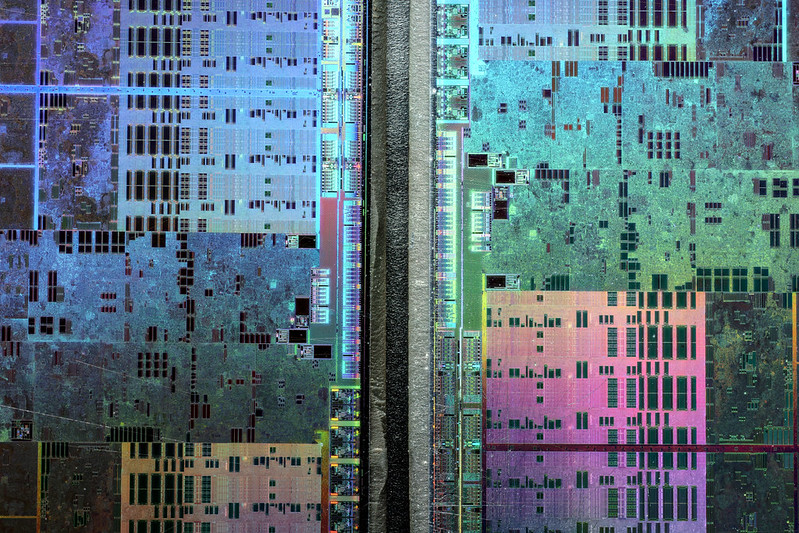

Carbon nanotubes possess exceptional properties, including high electrical conductivity, remarkable mechanical strength, and excellent thermal stability. These characteristics make them ideal candidates for creating a new generation of thick film resistors that outperform existing technologies. Our CNT-based thick film resistors leverage these inherent advantages to deliver unmatched performance in demanding applications.

Key Advantages of Our Carbon Nanotube Thick Film Resistors:

High-Power Handling (High-Power Thick Film Resistor): CNTs excel at dissipating heat. Our resistors are engineered to withstand significantly higher power loads compared to traditional thick film resistors of comparable size. This allows for miniaturization of power circuits without sacrificing performance or reliability. Specifically, the unique network structure formed by CNTs within the thick film matrix enables efficient heat transfer, preventing localized hot spots and ensuring stable operation at elevated power levels. We've achieved demonstrably superior power handling capabilities in rigorous testing, exceeding industry standards.

Ultra-Low Temperature Coefficient of Resistance (Low-TCR Thick Film Resistor): Temperature variations can significantly affect the resistance value of conventional resistors, leading to inaccuracies and performance degradation. Our CNT thick film resistors exhibit an exceptionally low Temperature Coefficient of Resistance (TCR). This means that the resistance value remains remarkably stable across a wide temperature range, ensuring consistent and reliable performance in diverse operating environments. This stability is crucial for precision applications in instrumentation, measurement, and control systems. Our innovative formulation and processing techniques minimize the inherent TCR of the carbon nanotubes themselves, resulting in a truly exceptional low-TCR product.

Tailored Resistivity and Performance: Using a carefully formulated paste with a resistivity of 5 Ω.cm, we can precisely control the electrical properties of our CNT thick film resistors. This allows us to tailor the resistance value to meet specific customer requirements. The 5 Ω.cm resistivity provides an optimal balance between sheet resistance and film thickness, leading to excellent performance characteristics. We offer a range of resistance values and power ratings to perfectly match your application needs.

Enhanced Stability and Reliability: The robust nature of carbon nanotubes contributes to the exceptional long-term stability and reliability of our thick film resistors. They are less susceptible to degradation from environmental factors such as humidity, temperature cycling, and chemical exposure.

Compact Size and Miniaturization: The superior power handling capabilities of our CNT thick film resistors allow for the use of smaller components, contributing to overall circuit miniaturization. This is particularly beneficial in applications where space is limited, such as portable devices, automotive electronics, and aerospace systems.

Applications:

Our carbon nanotube thick film resistors are ideal for a wide range of applications, including:

Power Supplies

Motor Control

Automotive Electronics (e.g., Battery Management Systems)

LED Lighting

Industrial Automation

Instrumentation

Measurement and Control Systems

Renewable Energy Systems (e.g., Solar Inverters)

The Future of Resistor Technology

Carbon nanotube thick film resistors represent a significant advancement in resistor technology, offering a compelling combination of high power handling, low TCR, and exceptional stability. With our expertise in CNT materials and thick film processing, we are committed to delivering innovative solutions that meet the evolving needs of our customers.

Contact us today to learn more about our carbon nanotube thick film resistors and how they can improve the performance of your products. Let us help you revolutionise your own designs with the high-power, low-TCR solution that only CNT technology can provide.

![[The AI Show Episode 144]: ChatGPT’s New Memory, Shopify CEO’s Leaked “AI First” Memo, Google Cloud Next Releases, o3 and o4-mini Coming Soon & Llama 4’s Rocky Launch](https://www.marketingaiinstitute.com/hubfs/ep%20144%20cover.png)

![From fast food worker to cybersecurity engineer with Tae'lur Alexis [Podcast #169]](https://cdn.hashnode.com/res/hashnode/image/upload/v1745242807605/8a6cf71c-144f-4c91-9532-62d7c92c0f65.png?#)

![BPMN-procesmodellering [closed]](https://i.sstatic.net/l7l8q49F.png)

.jpg?#)

_Tanapong_Sungkaew_via_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

.png?#)

![CMF Phone 2 Pro has a dual-tone design and improved camera in latest teasers [Gallery]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/04/cmf-phone-2-pro-camera-tease.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Apple Releases iOS 18.5 Beta 3 and iPadOS 18.5 Beta 3 [Download]](https://www.iclarified.com/images/news/97076/97076/97076-640.jpg)

![Apple Seeds visionOS 2.5 Beta 3 to Developers [Download]](https://www.iclarified.com/images/news/97077/97077/97077-640.jpg)

![Apple Seeds tvOS 18.5 Beta 3 to Developers [Download]](https://www.iclarified.com/images/news/97078/97078/97078-640.jpg)

![Apple Seeds watchOS 11.5 Beta 3 to Developers [Download]](https://www.iclarified.com/images/news/97079/97079/97079-640.jpg)

![Mobile Legends: Bang Bang [MLBB] Free Redeem Codes April 2025](https://www.talkandroid.com/wp-content/uploads/2024/07/Screenshot_20240704-093036_Mobile-Legends-Bang-Bang.jpg)