Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space. What is Industrial Robotics Programming? Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks. Popular Robotics Programming Languages RAPID – Used for ABB robots. KRL (KUKA Robot Language) – For KUKA industrial robots. URScript – Used by Universal Robots. Fanuc KAREL / Teach Pendant Programming ROS (Robot Operating System) – Widely used open-source middleware for robotics. Python and C++ – Common languages for simulation and integration with sensors and AI. Key Components in Robotics Programming Motion Control: Programming the path, speed, and precision of robot arms. Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control. PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation. Safety Protocols: Programming emergency stops, limit switches, and safe zones. Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots. Sample URScript Code (Universal Robots) # Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper Software Tools You Can Use RoboDK – Offline programming and simulation. ROS + Gazebo – Open-source tools for simulation and robotic control. ABB RobotStudio Fanuc ROBOGUIDE Siemens TIA Portal – For integration with industrial control systems. Steps to Start Your Journey Learn the basics of industrial robotics and automation. Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc). Get comfortable with control systems and communication protocols (EtherCAT, PROFINET). Practice with simulations before handling real robots. Study safety standards (ISO 10218, ANSI/RIA R15.06). Real-World Applications Automated welding in car manufacturing. High-speed pick and place in packaging. Precision assembly of electronics. Material handling and palletizing in warehouses. Conclusion Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

- RAPID – Used for ABB robots.

- KRL (KUKA Robot Language) – For KUKA industrial robots.

- URScript – Used by Universal Robots.

- Fanuc KAREL / Teach Pendant Programming

- ROS (Robot Operating System) – Widely used open-source middleware for robotics.

- Python and C++ – Common languages for simulation and integration with sensors and AI.

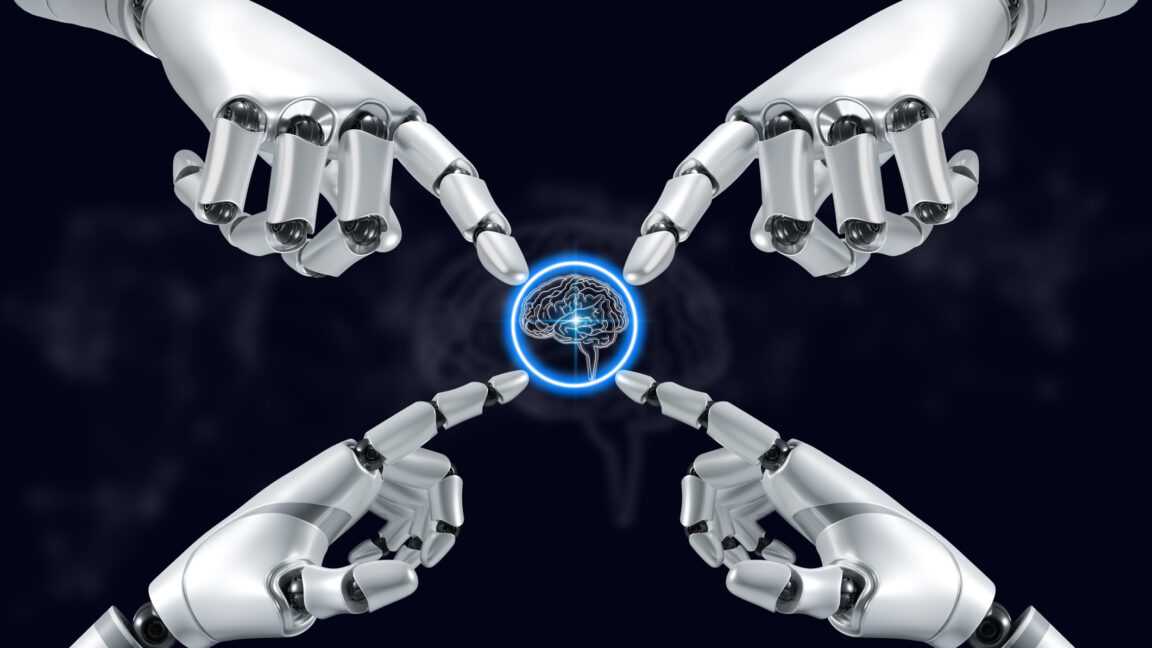

Key Components in Robotics Programming

- Motion Control: Programming the path, speed, and precision of robot arms.

- Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

- PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

- Safety Protocols: Programming emergency stops, limit switches, and safe zones.

- Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position

movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05)

Gripper control (example function call)

set_digital_out(8, True) # Close gripper

sleep(1)

set_digital_out(8, False) # Open gripper

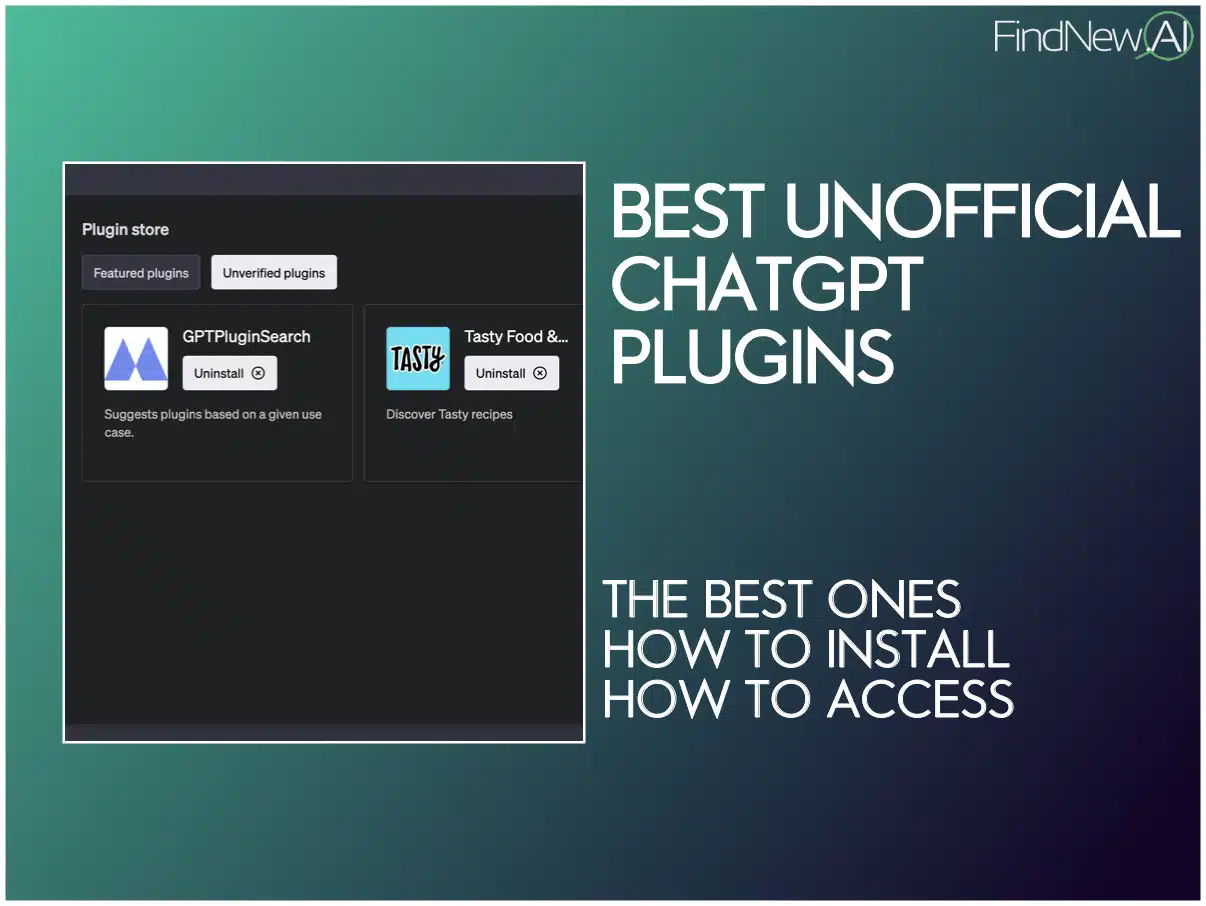

Software Tools You Can Use

- RoboDK – Offline programming and simulation.

- ROS + Gazebo – Open-source tools for simulation and robotic control.

- ABB RobotStudio

- Fanuc ROBOGUIDE

- Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

- Learn the basics of industrial robotics and automation.

- Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

- Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

- Practice with simulations before handling real robots.

- Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

- Automated welding in car manufacturing.

- High-speed pick and place in packaging.

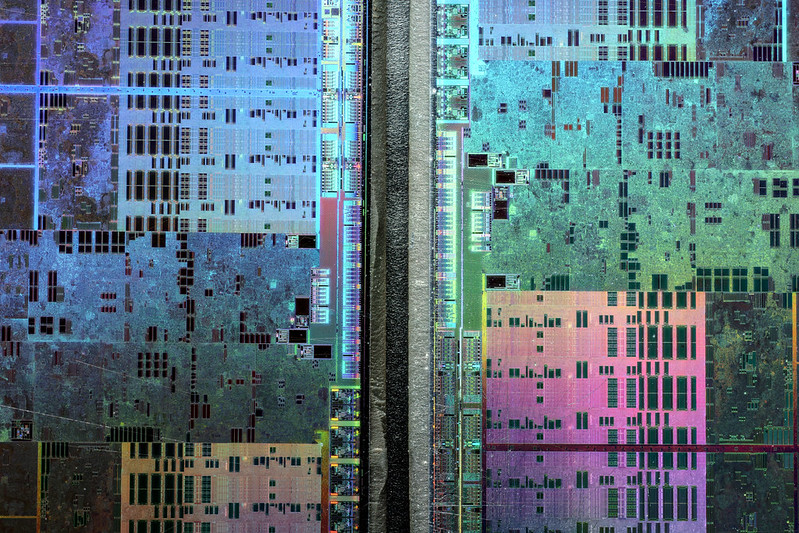

- Precision assembly of electronics.

- Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

![[The AI Show Episode 144]: ChatGPT’s New Memory, Shopify CEO’s Leaked “AI First” Memo, Google Cloud Next Releases, o3 and o4-mini Coming Soon & Llama 4’s Rocky Launch](https://www.marketingaiinstitute.com/hubfs/ep%20144%20cover.png)

![Rogue Company Elite tier list of best characters [April 2025]](https://media.pocketgamer.com/artwork/na-33136-1657102075/rogue-company-ios-android-tier-cover.jpg?#)

.webp?#)

![Here’s the first live demo of Android XR on Google’s prototype smart glasses [Video]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/04/google-android-xr-ted-glasses-demo-3.png?resize=1200%2C628&quality=82&strip=all&ssl=1)

![New Beats USB-C Charging Cables Now Available on Amazon [Video]](https://www.iclarified.com/images/news/97060/97060/97060-640.jpg)

![Apple M4 13-inch iPad Pro On Sale for $200 Off [Deal]](https://www.iclarified.com/images/news/97056/97056/97056-640.jpg)