Deep Dive on Panel Making

It is easier than ever to produce projects with nice enclosures thanks to 3D printing and laser cutting. However, for a polished look, you also need a labeled front panel. …read more

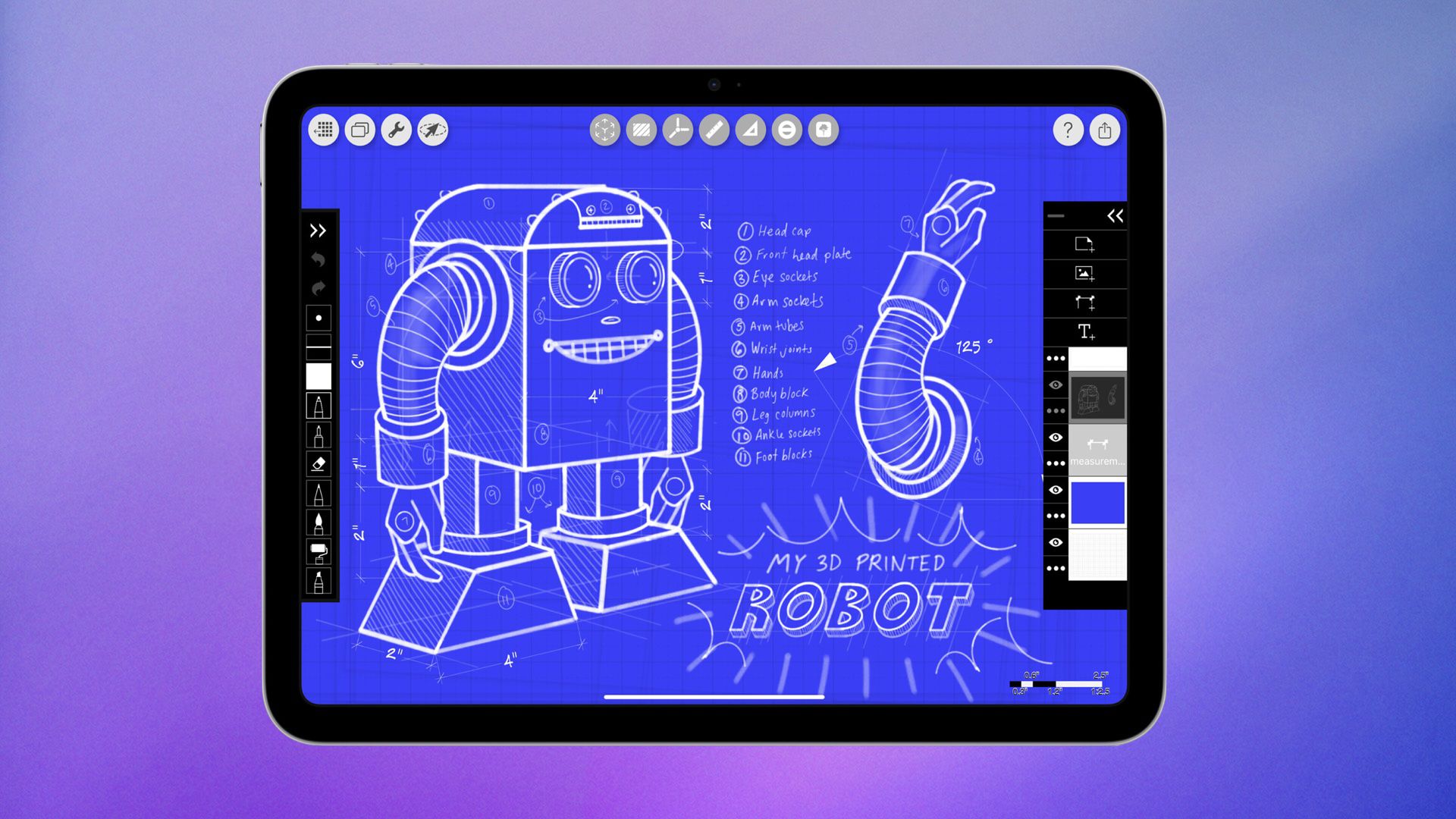

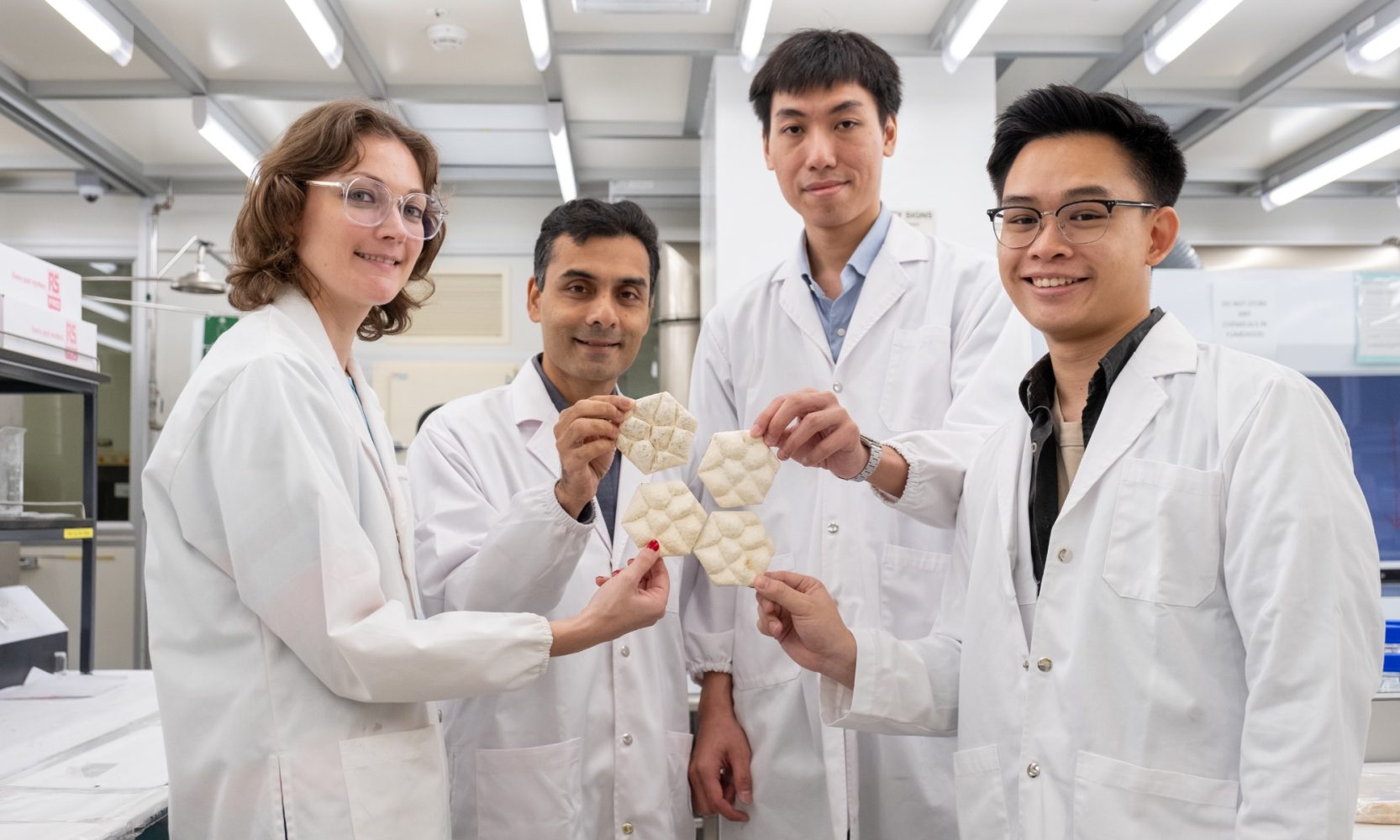

It is easier than ever to produce projects with nice enclosures thanks to 3D printing and laser cutting. However, for a polished look, you also need a labeled front panel. We’ve looked at several methods for doing that in the past, but we enjoyed [Accidental Science’s] video showing his method for making laminated panels.

His first step is to draw the panel in Inkscape, and he has some interesting tips for getting the most out of the program. He makes a few prints and laminates one of them. The other is a drill guide. You use the drill guide to make openings in the panel, which could be aluminum, steel, plastic, or whatever material you want to work in.

The laminated print goes on last with just enough glue to hold it. Is it a lot of work? You bet it is. But the results look great. There are a number of things to look out for, so if you plan to do this, the video will probably save you from making some mistakes.

There are many ways to get this job done. We’ve asked you for ideas before and, as usual, you came through. If you want a different take on laminated panels, there are a few different tips you can glean from this project.

![[The AI Show Episode 143]: ChatGPT Revenue Surge, New AGI Timelines, Amazon’s AI Agent, Claude for Education, Model Context Protocol & LLMs Pass the Turing Test](https://www.marketingaiinstitute.com/hubfs/ep%20143%20cover.png)

![[DEALS] Koofr Cloud Storage: Lifetime Subscription (1TB) (80% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

![Is this too much for a modular monolith system? [closed]](https://i.sstatic.net/pYL1nsfg.png)

-The-Elder-Scrolls-IV-Oblivion-Remastered---Official-Reveal-00-18-14.png?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

_roibu_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

CISO’s Core Focus.webp?#)

![Apple Smart Glasses Not Close to Being Ready as Meta Targets 2025 [Gurman]](https://www.iclarified.com/images/news/97139/97139/97139-640.jpg)

![iPadOS 19 May Introduce Menu Bar, iOS 19 to Support External Displays [Rumor]](https://www.iclarified.com/images/news/97137/97137/97137-640.jpg)

![Apple Drops New Immersive Adventure Episode for Vision Pro: 'Hill Climb' [Video]](https://www.iclarified.com/images/news/97133/97133/97133-640.jpg)